| Prod Model: |

XL-2015-001 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Mid East,Eastern Asia,Western Europe |

| Application: |

Communication Industry |

| Material: |

Steel |

Product Description

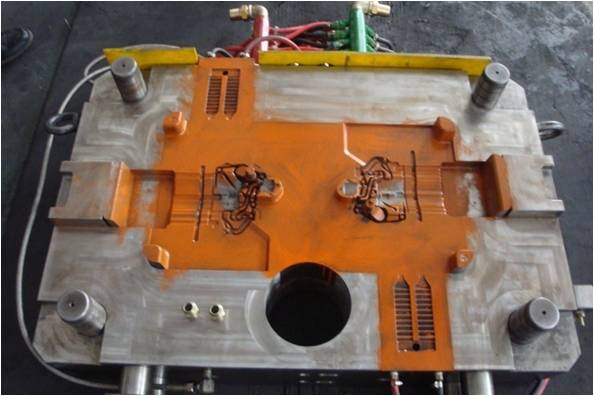

products: die casting mould of oil pump housing

customer: magna

mould material: dievar

mould frame: p20

cooling: water cooling

service life: 100, 000shots

die casting machine: 800T

| item | description |

die casting mold

parts | die casting mold products model | xinlinmold |

| die casting mold products molding technics | die casting mold |

| part material: | adc12, a380, , a390

and many other aluminium alloy are all acceptable., magnesium alloy |

| die casting mold products dimension | as drawings or samples |

| die casting molds | die casting mold cavity | single or multiple |

| die casting mold material | h13, dievar, 8407, skd61,

45#steel, etc. |

die casting molds

heat treatment | hardened, nitriding |

die casting molds

hardness | hrc50~55 |

die casting molds

feature | advanced design, novel structure, high precision,

quality materials, long lifetime, short delivery time |

die casting mold making equipment and

die casting moulds checking machine | cnc precision machining, die casting moulds engraving machine, cnc forming machine,

cnc turning, edm, linear cutting machine, die spotting machine(100~300t),

die casting machine(180t~800t), lathe, grinding machine;

cmm, material detector, hardness test device, spectrograph, etc. |

| die casting mold design software | cad, ug, pro/e, jscast of japan, , etc. |

die casting molds

quality certification | iso9001: 2008 |

die casting moulds

advantage |

die casting molds

quality | insist on making every detail carefully always |

die casting molds price | reasonable and competitive price |

die casting molds delivery time | never later than the delivery time in contract |

die casting molds service | 1.6x8 hrs helpline

2. commissioning

3. training

4. technical on-site support

5. repairs

6. spare parts distribution

7. tele-service

8. condition of your machine

9. maintenance |

die casting molds r&d | plentiful experience and skillful technique on die casting |

die casting molds team | united and positive team |

|

| aluminum die casting mold making process. how to make die cast molds? |

| 1. r&d | we support customer r&d. make the files or improve the design if you needed. |

| 2. negotiation | the quality, price, material, delivery time, payment item, ect. |

| 3. place an order | according your own design or you chooses our design. |

| 4. mould | 1. mold design

2. mold making

a. cnc machining

b. cavity heat treatment ( quenching)

c. grinding

d. cnc fine machining

e. edm (electron discharge machining)

f. wedm(wire electrical - discharge machining)

g. cavity polishing

h. assembly mold, mold spotting

3. trial mold

4. mold delivery |

| 5. sample shoot | if the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

| ↓ |

| 6. products in store | if your quantity is beyond our storage, we will provide lead time to you. |

| ↓ |

| 7. delivery | delivery goods by sea or by air, according customers requirement. |

Ningbo Beilun Xinlin Electromechanical Mould Co., Ltd. Is located in Chunxiao, Beilun, Ningbo where has a world-famous port and is well-known as 'Land of Die-casting Moulds'. We have two plants, one is in Chunxiao, the other is in Daqi High grade Mould park.

The company was founded in 2003 and in the same year it passed the strict certification of ISO9001 quality management system. The company has more than 20 senior technical personnel and specializes in design and manufacture of various precision aluminium, magnesium and vacuum die-casting moulds and also has a production capacity of 200 sets of medium and large die-casting moulds annually.

Now the company has successfully provided many sets of die-casting moulds as support parts for a number of foreign-funded enterprises in China, including GF and SEW in Suzhou, BSH and ZF in Nanjing, Sensus in Yangzhou, WABCO in Jinan and BorgWarner and ABB in Beijing. Also the company's die-casting moulds have been exported to many foreign companies such as Ariston in France, Polaris in USA and TVS in India.

Hardworking makes us be excellent and strictness makes our clients be satisfying. We will keep on improving our work in order to exceed our customers' expectations.