| Prod Model: |

Various |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Processing Type: |

Preheat Equipment |

| Capacity: |

300tpd |

| Certificate: |

ISO9001: 2008 |

| Keyword: |

Rotary Kiln / Cement Rotary Kiln / Cem... |

| Motor Power: |

115 Kw |

| Warrenty: |

1 Year |

| Type: |

Preheat Equipment |

| Mining Object: |

Metallic and Non-Metallic Ore Excavator |

| Object: |

Clay |

| Condition: |

New |

| Model: |

Φ2.2×20 |

| Voltage: |

380-450V |

Product Description

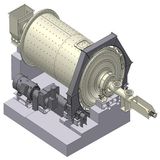

Vertical Preheater Introduction

Limestone system consists of vertical preheater, rotary kiln and cooler vertical compostion, the material from the pre-heater under the feed chute at the top of the silo by the preheater into the body.

Vertical Preheater Application:

Vertical preheater is one of the main equipments of active limestone. The main function is to send limestone materials sent by the upper part to the preheater body, while using the emitted high temperature gas (1150 ) after calcination, preheat the materials to about 900 evenly. During the preheat process, 30% CaCO3 is decomposed in the preheater, then by the hydraulic pressure stick putting into the rotary kiln to calcinate. This kind of technology not only shortens the calcined time in the kiln, but also can obtain higher degree of activity of the lime.

Structure

Vertical preheater system mainly consists of six main parts.

1, the upper feeding system: Includes the upper hopper, the next material possession, the next feeding method and structure can guarantee to the pre-heater of the body feeding to achieve security when closed, so that the cold air from outside can not enter into the preheater, and feeding can make use of valve rod to achieve continuous or intermittent feeding.

2, preheater body: It is to ensure that material preheated to 900 degrees Celsius of the most important part, it is by the warm room, hanging devices and brick lining (which does not belong to the scope of design and manufacturing equipment) and other parts. That part of the structure of most of metal structures, part of the material according to the need to use a heat-resistant steel, heat-resistant steel to 1100 degrees celsius in 1000 to work under high temperatures. In addition, the refractory bricks lining structure, novel design, sealing is good, can guarantee the material in pre-heater evenly and achieve pre-heating temperature preheating.

3, pusher devices: Mainly Tuitou, framework, and connecting rods and other parts of Tuitou using heat-resistant steel casting or welded together, can withstand high temperatures, using electronic control and hydraulic systems can be by putting the various hydraulic automatic control program to achieve sequential pusher.

4, the hydraulic system: Includes tanks, pumps, motors, solenoid valves, hydraulic tubing, etc., his main role is to control the pusher device to push the completion of material movement.

5, bottom feeding room: The main include slide tube, feeding the main room, feeding slip mouth and so on, its main role is to import the materials after preheating rotary kiln calcination.

6, Framework: It includes columns and ring beam and so on, the main role is to carry The upper part of the structure.

| Model | Capacity(t/d) | Power(kw) | Push rod qty | Materials of pusher |

| HX-2-6 | 200 | 18.5 | 6 | refractory steel |

| HX-3-8 | 300 | 18.5 | 8 |

| HX-4-8 | 400 | 22 | 8 |

| HX-5-12 | 500 | 25 | 12 |

| H-6-12 | 600 | 25 | 12 |

| HX-8-18 | 800 | 34 | 18 |

| HX-10-22 | 1000 | 45 | 22 |

Zhengzhou Hengxing Heavy Equipment Co., Ltd. is a joint stock corporation integrating research and manufacture sale with the targt at the large and medium sized series of heavy equipment for mine machinery, wall materies, formed coal, metallurgy and etc. The company is located at No. 8 Hongye Road, West Hehuan Street, High-Tech Development Zone, Zhengzhou, China.

Since establishment, our company has gathered a group of scientific elites with modernized management system and accurate production as well as independent innovation. Furthermore, our company has realized the computer informationization of management, production, and the CAD and CAPP of production research and process design within our company. Our company is equipped with powerful machines and equipment for machining, forging, rivet welding, and carburization heat processing. At the same time the company has established long-term cooperative relationships with many research institutes from at home and abroad. With advanced technology, we can process and develop new products and promote new technology.

We adhere to the guideline of "survive on high quality, develop by good credit" on the basis of market development and customer service. We have provided better social and economic benefits and attained ISO9001-2000 Certificate. Our products sell very well at home and abroad, enjoying very high appraisement from users.

We would like to offer the most advanced technology, reliable quality, and preferential prices centering on clients. Improving customer satisfaction, we sincerely hope to co-operate with new and old customers, jointly creating the new glorious century.