| Prod Model: |

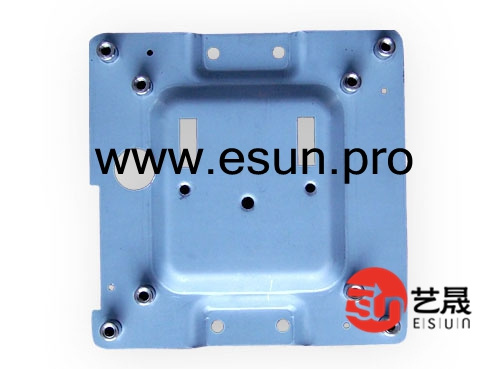

SD049 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Material: |

Alumium,Brass,Iron Sheet,and So on. |

| Finish: |

PVC Powder Coating, Dichromate Plating |

| Package: |

Single Polybag, Bubble Bags, Wooden Case |

| MOQ: |

Trial Order Without MOQ |

| Quality Control: |

ISO/9001:2008 |

Product Description

Stainless Steel Deep-Drawn for electronic component

Esun Design and manufacture various Deep-Drawn, Steel Deep-Drawn, Stainless Steel Deep-Drawn, deep drawn parts, Deep Drawn Stamping Part, Deep Drawing Part, stamping parts, sheet metal parts, plastic injection parts and other mechanical parts, including washer parts, dryer parts, automotive parts, bicycle parts, kitchen equipment parts and plastic parts, etc.

Description of metal stamping 2:

1. Material: Carbon steel (cold rolled steel, hot rolled steel), galvanized steel, stainless steel, brass, aluminum, aluminized steel, etc.

2. Process: Stamping, deep drawing, punching, bending, welding, riveting, finish, etc.

3. Surface Treatment: All kinds of surface treatment is available: Polishing, zinc plating, nickel plating, chrome plating, powder coating, electrophoresis and others

4. Equipment: We have 635T hydraulic press machine, 500T hydraulic press machine, machining center, as well as the machines for stamping, bending, grinding, milling, drilling, welding, polishing, injection, molding and other equipments for mechanical usage.

5. Size: According to customer's design or sample

6. Mould: We are capable and experienced in designing, developing and manufacturing mold by our own.

7. Sample confirmation: We will modify the mould untill customer satisfied

8. Packing: According to customer's requirement

9. Delivery: On time delivery, by sea or by air

|

Equipment |

1) Stamping machine & hydraulic press machine |

2) Spot welding machine, Argon arc welding machine,

3) Gas welding machine |

3) Spring machine, CNC Milling and Turning, Grinding, Honing,

4) Lapping, Broaching and other secondary Machining, Meter Lathes |

|

4) Line-cutting Machine, Laser-cutting Machine |

|

Test Equipment |

Hardness tester, Chemical analysis, Digital Measuring Projector,

Dynamic Balancing Tester, Plating Tester |

|

Material |

Carbon steel (cold rolled steel, hot rolled steel), galvanized

steel, stainless steel, brass, aluminum, aluminized steel, etc. |

|

Process |

Stamping, deep drawing, punching, bending, welding, riveting,

finish, etc. |

|

Surface Treatment |

Polishing, zinc plating, nickel plating, chrome plating,

powder coating, electrophoresis and others |

|

Service |

OEM orders are welcomed, Small Order Allowed,

Sample Product Available, Competitive Price, High quality. |

|

certificate |

ISO9001-2000 |

|

Packing |

According to customer' s requirement |

|

Delivery time |

On time delivery. |

|

Payment terms |

TT, L/C |

|

|

In 2006, Hongkong: Esun Industry started business of metal project, mainly supplied Toshiba lighting of Japan die casting and CNC parts, and some assemble lighting parts.

In 2008, China: Esun Industry found the first die casting factory MY in dongguan city, which is speaclizing in die casting parts.

In 2010, MY passed ISO9001: 2008 quality system.

In 2011, Oversea office set up in Australia, dealing with die casting, CNC and metal sheet fabrication.

In 2014, China: Esun Industry found the second factory TC hardware-electric in dongguan city, which is speaclizing in assembling Lighting.

In 2014, China, TC passed ISO9001: 2000 quality system.