| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Deformation Temperature: |

Hot Forging |

| Molding Style: |

Forging |

| Molding Technics: |

Pressure Casting |

| Casting Method: |

Sand Casting |

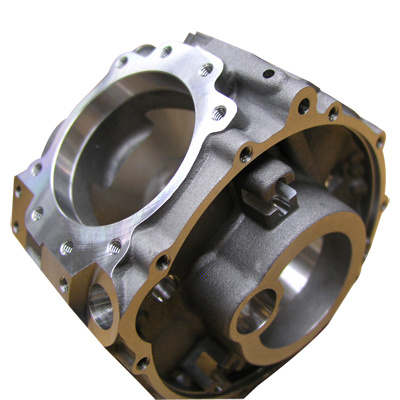

Product Description

1. Type of casting: Lost -wax casting

2. Material: Aluminium, brass, stainless steel, alloy

3. Size: From 1mm to 300mm

4. Weight: From 1g to 50kg

|

Product name |

Die casting mould |

|

Material of mould |

45#/P20/H13/718HH/S136/SKD61/S45/P20/H13/3C117/2136 |

|

Product material |

aluminimum, copper, steel, stainless steel, carbon, iron ect. |

|

Standard |

Nonstandard JIS, DIN, BS, ASTM, SAE |

|

Mould base |

LKM, HASCO |

|

Runner |

Hot |

|

Cavity |

single/multi |

|

Design software |

UG, PROE, Solidworks, CAXA, Cimatron, |

|

For use |

machine parts |

|

Processing facilities |

provide casting , stamping, CNC machine, heat treating and finish treatment |

|

Step: |

|

|

1. Clients offer 3D /2D drawing and enough information about mould and product. |

|

2. We will offer the quotation for mould and plastic according to client’ s requirement within 4 hours |

|

3. Client confirm the price and give us your advice and make agreement with the price , delivery , package, payment terms and so on. |

|

4. After signing the contract and accepting customer’ s prepayment, we will arrange for designing and manufacturing the mould according to the second confirmed drawing. |

|

5. Trial samples or products will be sent to client and get client confirment and feedback, and see if there is any modification before finished products. |

|

6. We will finish the products in regulated time. |

Our company was founded in 1992, as a private joint-stock enterprise. We are the member enterprise of China Association Of Mold, with the existing staff of 50 people and a plant area of 4000 square meters. Our factory is equipped with all kinds of mold manufacturing equipment, including four sets of large machining centers, 10 sets of machine tools, 3 sets of CNC EDMs, milling / planning / grinding / bending machines, shears, 10 sets of 1-100T punches, and others.

Xinglong Mold is able to skillfully manage milling, planning, grinding, drilling, EDM, wire cutting, and CNC machine operators and has extensive practical experience in mold assembly and technical personnel. We hire more than 10 mold technicians with rich practical experience. The users can only provide sample parts or product drawings, and then we can offer high quality mold products to meet customers' requirements. Our firm can design and manufacture and process components as per users' needs.