| Prod Model: |

HSJ-218 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Material: |

Aluminum, Alloy, Stainless Steel, Brass, Copper, S |

| Process: |

Die Casting |

| Standrd: |

ISO,SGS |

| Place Of Origin: |

Shenzhen |

Product Description

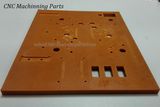

Iron Die Casting Process Precision Machined Components

1. Part Description:

Metal machining parts

Material: Aluminum, Alloy, Stainless Steel, Brass, Copper, Steel

Process: Die casting

MOQ: 1-10 PCS

Delivery time: 7-30days

2. Our Service:

Mechanical Parts and Fabrication Services for Customized Request We are professional in NC & CNC machining service and molding service for OEM and ODM parts. Types include turning, milling, grinding, stamping, bending, welding, die casting, drilling, tapping and plastic injection.

3. Our Factory:

Mechanical Parts and Fabrication Services for Customized Request

The machines are come from Taiwan, Japan as well as Germany. High precision and quality part is our always target, the tolerance we can reach +/-0.01mm(for meta part), +/-0.03mm for plastic part.

4. How to do business with us:

Mechanical Parts and Fabrication Services for Customized Request

5. Product Inspection:

Every part will be inspected during the machining and we will offer you the QC report before arrange shipping, Sure that all parts you received will meet your request.

6. ISO9001 2008 quality certificate approval:

High quality and best service is our habit, we have the specification machining and inspection process, do believed that our product will satisfied you.

7. Parts Information:

(1). Applicable Material---Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel

(2). Surface treatment---polishing, zinc plating, nickel plating, chrome plating, anodizing.

(3). Drawing format---IGS, SLD, X_T, STEP, CAD and PDF

(4). Tolerance: Plastic part can reach +/-0.03mm, metal part can reach +/-0.01mm

(5). Payment Terms: L/C, T/T, Paypal&Western Union is acceptable.

(6). Packagings: Standard package/ Pallet or container/As per customized specifications.

(7). Shipment Terms: Express&air freight priority/sea freight/ As per customized specifications.

8. Our Advantages:

(1). Advance machine and the skillful workers

(2). Low MOQ (1-10PCS is even acceptable in some special conditions)

(3). Short lead time (7-30days according to order qty)

(4). Customized size and drawing is available

(5). Near Shenzhen and HK, convenient transportation

(6). Have own the factory and the material price from wholesale

9. Currently market:

USA, Argentina, Canada, Australia, New Zealand, UK, France, HK, Singapore, Malaysia and so on...

We established strong relationships with our customers with unsurpassed customer support and a total commitment to quality and on time delivery. From the design phase to the parts and components being delivered to our customers, we take pride in the fact that we offer unprecedented integration and service to our customers.

10. FAQ:

(1). Question---Are you the trading company or factory?

Answer-----We have our own factory!

(2). Question---What`s the production capacity for your company?

Answer---Normally can reach 20, 0000 pieces annual.

(3). Question---How about the delivery time?

Answer---The delivery time will according to the part quantity, usually sample will need 7-10 days, and part production will need 25-30 days!

(4). Question---What`s the Scrap rate for the part?

Answer---Normally, the scrap rate is 3%~4%. However, we won't send you any scrap part, all the part will be 100% inspected by our quality department to make sure no available ones.

(5). Question---What we should do if we check out the part problem?

Answer---If you have received any unqualified part, please show us the pictures, after our engineers and QC department check, we will choose to help you repair or redo within 10~15 days according to rejected quantities.

Established in 2006, Shenzhen HongSheng Ji Technology Co., Ltd is a professional manufacturer specialize in the manufacturing precision machinery components and parts. We produce products in many field, such as electronics, optical communication, automotive, aerospace, industrial sensors, medical devices, mechanical component and sports

We have dozens of support equipment in our workshop, such as CNC milling machine/Horizontal CNC milling machine/4 Axis CNC Milling machine/5 Axis CNC milling machine/CNC Turing machine/Grinding machine/wire Cut machine, also have inspection equipment such as Two dimensional and three dimensional measuring instrument, digital projector, viedo measuring system, surface finishing testing machine...We're equipped to manufacture, inspect, assemble and deliver virtually any precision component as customer desire

From our establishment, ShenZhen HongShengJi has always put quality first, customer first, pioneering and innovative, and sustainable management, we commiten provide good service to our customer and become partner of many famous enterprise, We believe it is our responsibility to take all steps necessary to protect our environment.

We are looking forward to build long-term business relationships with you for mutual benefit. Customers from worldwide are warmly welcome to contact us. Welcome you to visit our factory for your business!