| Prod Model: |

MFS-100 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

Product Description

Specifications

1. Adopt IGBT

2. Steady performance

3. Small volum

4. Environmental protection

5. Well adapted 6. Heating fast

Applications:

1)M. F. Hot forging furnace is used for the heating of bars and rods larger than Φ 12, the material can be steel, stainless steel, copper, brass, Aluminum and so on.

2)The heating can be the whole rod, end of the rod or middle part of the rod.

3)Hot forging example: Fastening, screw, nut and so on

Structure characteristics:

The furnace includes medium frequency generator, compensating cap, working table, induction coil, coil cover, rod feeder and so on.

For some special applications, the infrared sensor, temperature controller and automatic rod feeding systems can also be included.

Main features of the M. F. Hot forging furnace:

1) Wide frequency range from 2KHZ to 20KHZ, frequency can be designed to satisfy different size of the heated rods.

2) The heating coil can be 500mm to 1 meter long, several pieces are heated at the same time to make sure the penetrating effect.

3) In the continuous heating process, the load inside the coil is stable, thus to overcome high heating power change caused by large change of the load during the heating course from room temperature to 1100 degree. The actual power can reach more than 85% of the rated power of the machine.

4) Even when heating non-ferrous metals like copper or aluminum, the actual power can also reach more than 85% of the rated power of the machine by design the coil properly and match the compensating cap correctly. 3.5KG copper or brass can be heated to 700 degree per kilowatt in an hour.

| Models | Rated output power | Frequency rage | Input current | Input voltage | Duty cycle | Water flow | Weight | Dimension |

| MFS-100 | 100KW | 0.5-10Khz | 160A | 3P 380V 50Hz | 100% | 10-20m³/h | 180kg | 620×680×1630mm |

We are specialized in the researching and manufacturing of transistor type medium and high frequency induction heating machine and related equipments. Our company was established in 1998 and is privately held.

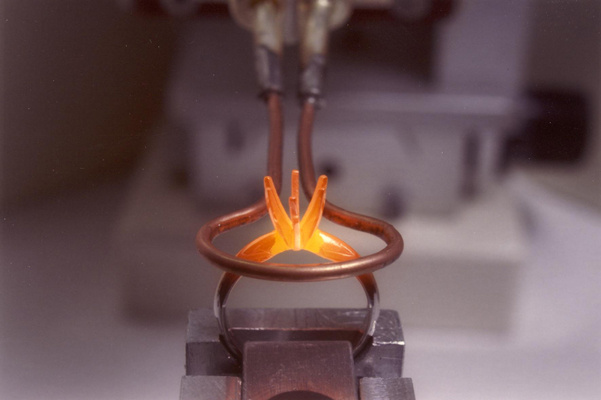

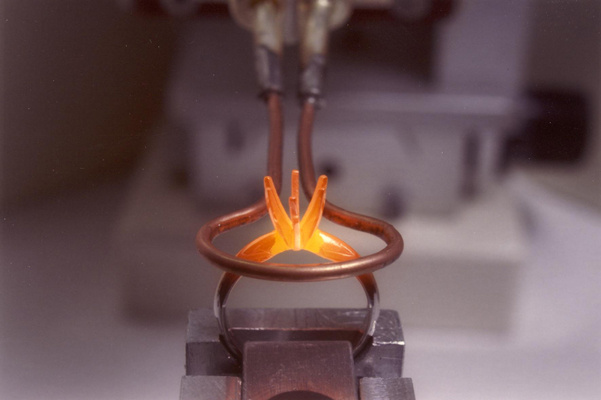

Precision induction heating solutions are our specialty. Use induction heating to improve the effiency and effectiveness of your industrial heating process. That are used for application such as brazing, heat treating, annealing, hardening, bonding, hot forging, melting, shrink fitting etc.

Our induction heating machines are available from 2kw to 750kw deliverable output power with 0.5kHz to 1.1MHz operating frequency range. And 100% solid state technology. All our products are divide into three major series according to the frequency:

Medium Frequency series (MF series)

High Frequency series (HF series)

Ultrahigh Frequency series (UF series)

Depend on our advanced technologies, reliable solutions and excellent after service, our induction heating machines are sell well at home and abroad.

Welcome to enquiry more information, any questions or technique support, please contact us via e-mail for details. Your satisfaction are our team's goal.