| Prod Model: |

GC-14 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Weight: |

Ranging From 0.01 Kg to 100kg |

| Service: |

OEM and ODM |

| Surface Ttreatment: |

Polishing, Anodising, Powder Coating etc |

| Product Capacity: |

1000000 PCS/Month |

| Export Markets: |

Global |

| Delivery Time: |

30 Days After Receiving The Payment |

| Material: |

Aluminum Alloy |

Product Description

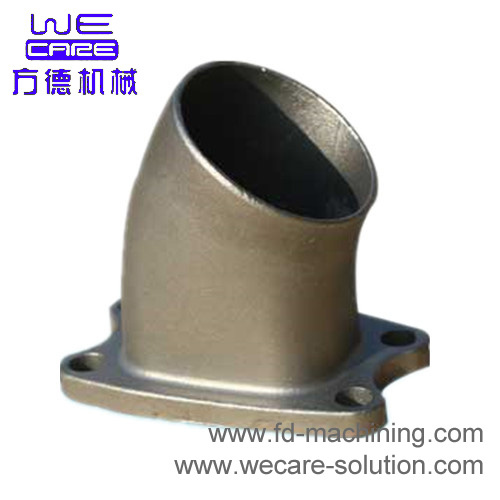

Good Quality Gear House of Gravity Casting in China With CE Certification

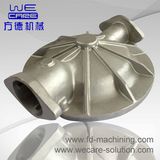

The die casting process provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical castings can be produced in a very short time.

Die castings have a long service life because they are durable, dimensionally stable, and heat resistant.

Die cast parts are stronger than plastic injection molded parts having the same dimensions. Die castings can be produced with thinner wall sections that are not possible with other casting methods.

Die castings can be smooth or textured and they are easily plated or painted with a minimum of surface preparation.

Die castings offer simplified assembly by providing integral fastening elements such as bosses and studs. Holes can be cored and made to tap drill sizes or external threads can be casted.

Permanent molding is desired by those requiring an aluminum casting with good density and superior mechanical properties. Castings made with this method are much more dimensionally accurate and repeatable than those made using sand methods. This reduces or eliminates much of the machining that may be required.

Advantages: Very repeatable, sound density, can utilize cores in the casting design, short lead times, excellent appearance, tight tolerances, perfect for high volume.

| Process available | silica sol,sodium silicate (soluble glass) and compound process |

| Material available | Duplex stainless steel,stainless steel,carbon steel, Alloy Steel, and etc. |

| Standard | ASTM or as your requirement |

| Product | all kinds of casting(unit weight ≥0.1kg) |

| Surface finish | Passivation,polishing or as your request |

| Applied software | Pro/E, Auto CAD, Solid Work 2001,CAXA, UG, CAD/CAM/CAE |

| Production capacity | more than 2,000MT per year |

| heat treatment: | anneal, quenching, normalizing, carburizing,polishing, plating |

| Machining | CNC and NC machining, turning, milling, drilling, boring, threading, grinding machines and test facility |

| Certification | ObtainISO9001:2008Quality System Certified and CE/PED Certified by TUV |

Wecare Industrial Company is a world leader in the custom design and manufacture of metal component parts.

We are a full-service company. Our experienced engineers and manufacturing staff are ready to assist you with the design of your custom industrial components and produce the finished part. Our manufacturing capabilities include machined parts, die castings, sand casting and investment castings using the most advanced equipment.

Our services including the following;

. Engineering design of your custom component part

. AutoCAD and Solidworks 3-D support and service

. Production process support and quality control

Please give Wecare an opportunity to work with you. We pride ourselves on the high quality of our engineering and manufacturing, superior quality control and on-time delivery of your parts. Just as important is that we offer very aggressive prices in an effort to build a strong, long term relationship with our customers. We can provide you with a list of our customers upon request.

Wecare is headquartered in the city of Changzhou, Jiangsu Province, China. We have a satellite office in New Jersey for the benefit of our many USA customers.

What concerns you, What we care and focus.

You Trust, We care

We care quality-consistency and timely delivery;

We care to save your costs, to increase your competitiveness;

We care not only present cooperation, but future and long-term collaboration as well