| Prod Model: |

DR182 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Process: |

Forging and Machining |

| Molding Style: |

Forging |

| Processing Object: |

Metal |

| Molding Technics: |

Hot Forging |

Product Description

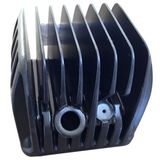

customized carbon steel die forging part for auto

1,material: carbon steel, stainless steel, alloy steel, aluminium alloy, zinc alloy etc.

2,surface treatment: sand blast, polishing, electroplating, electroless nickel plating, hot galvanizing, spray coating, dacromet etc.

3,heat treatment: quenching, annealing, tempering, normalizing etc.

4,process: die casting, investment casting, gravity casting, hot forging, maching, stamping etc.

5,packing: as customer's require

Delron Profile

Capability:

Technical assistance and consultation services are also available to serve customer's needs for prototyping and design optimization.

Multiple Manufacturing Capabilities:

l High-accuracy CNC Machining

l Turning

l Milling

l Grinding

l Honing

l Passivation

l Annealing/Heat Treating

l Etching/Passivation

l Chemical Cleaning

l Ultra-sonic Cleaning

l Shot-blasting

l Anodizing

Main products:

1, Auto parts: connecting rod, shaft, gear, banjo fitting, fastener etc.

2, Machinery parts

3, Electronic Accessories : LED light Radiators & Housings ect.

4, Agricultural Machinery Parts

Facility:

A wide range of horizontal and vertical machining centers with 3, 4 and 5 axis capabilities.

CNC lathes with milling and drilling capabilities, and various manual machines for grinding, turning, milling, drilling, cutoff and honing.

Quality & Testing

Monitored by detailed First Article, In-process, Final Inspection procedures and formal documentation.

All materials are inspected and documented upon arrival from approved suppliers.

Statistical process control techniques are used throughout manufacturing facilities, and attained TS 16949 and ISO 9001 certification.

Test equipment includes, Projector, Profile Meter, Metallography Instrument, Roughness Meter, Digital Caliper, No-go Gauge, etc.

| Services | Casting, forging, machining etc. |

| products | Connecting rod, rocker arm, shaft, bushings, flanges, gear, housing etc. |

| material | Carbon steel, cast steel, ductile iron, aluminium alloy, brass, stainless steel etc. |

| Surface treatment | Polishing, spray coating, deburring, electroplating, oxygenation etc. |

| CE | ISO9001, TS16949 |

| services | casting, forging, machining etc. |

| products | connecting rod, rocker arm, shaft, bushings, flanges, gear, housing etc. |

| material | carbon steel , cast steel, ductile iron, aluminium alloy, brass, stainless steel etc. |

| surface treatment | polishing, spray coating, deburring, electroplating, oxygenation etc. |

| CE | ISO9001, TS16949 |

Located in Ningbo China, Delron Industrial Co., Ltd. Has specialized in metal processing and precison machining since 1990. Our manufacturing capabilities and services consist of CNC machining, turning, milling, honing, forging, casting and product assembly. And our products include bushing, flange, connecting rod, housing and gear etc.

We provide quality products, delivered on time, at the lowest possible cost for our customers from a variety of background such as automobile, sewing, electrical tool, transportation, aviation and other industrial markets. Our manufactured custom made parts, range from 'one off's' to high quantities and can assist customer in solving the most challenging CNC machining assignments.

Recognizing that skilled people and technological growth is the keystone for success in today's global marketplace, Delron continues to commit resources to remain a leading place in the industry. From product concept development to contract manufacturing and Kan Ban delivery, Delron contributes all efforts to driving increased value for our customers