|

|

|

Index of Isotatic Graphite |

|

Grade |

JIC1-BD |

JIC2-SJ |

JIC3-LZ |

JIW4-GC |

|

BD |

BD2 |

SJ1 |

SJ2 |

SJ3 |

LZ1 |

LZ2 |

LZ3 |

LZ4 |

GC1 |

GC2 |

|

Bulk Density ≥g/cc |

1.85 |

1.80 |

1.80 |

1.75 |

1.70 |

1.85 |

1.80 |

1.75 |

1.70 |

1.80 |

1.85 |

|

Electric Resistivity µΩm |

10~12 |

11~13 |

15 |

15 |

15 |

15 |

15 |

15 |

15 |

13 |

13 |

|

Compressive Strength Mpa |

90 |

86 |

80 |

65 |

55 |

90 |

86 |

65 |

55 |

70 |

85 |

|

Flexural Strength Mpa |

45 |

40 |

37 |

28 |

25 |

45 |

40 |

28 |

25 |

40 |

45 |

|

Shore Hardness |

60 |

50 |

55 |

50 |

50 |

60 |

55 |

50 |

50 |

45 |

56 |

|

Ash Content PPM |

500/50 |

500/50 |

700/50 |

700/50 |

700/50 |

700/50 |

700/50 |

700/50 |

700/50 |

800 |

800 |

|

Average Granularity µ m |

22 |

22 |

22 |

22 |

22 |

22 |

22 |

22 |

22 |

13 |

13 |

|

Coefficient of Thermal Expansion ×10-6/centigrade |

4.3 |

4.1 |

4.0 |

3.8 |

3.6 |

4.3 |

4.0 |

3.8 |

3.5 |

3.2 |

3.5 |

|

Young's Modulus Gpa |

11.5 |

10 |

11.5 |

10.5 |

9.5 |

11.5 |

11.5 |

10.5 |

9.5 |

11 |

11 |

|

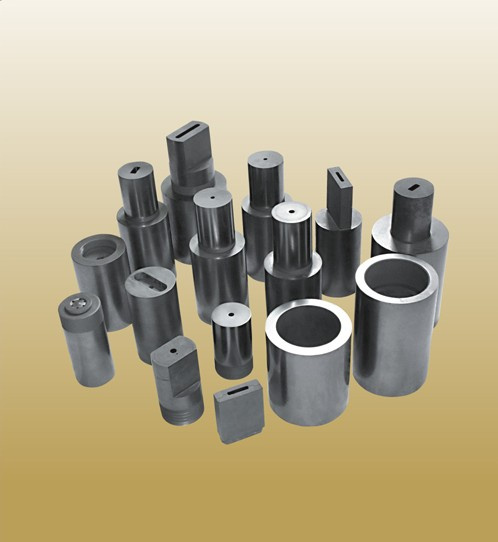

Applications |

Semiconductor(Monocrystalline silicon),ceramic sinter,vacuum furnace,electronic products sinter,continuous casting |

cemented carbide sinter,vacuum furnace,diamond sinter,precious metals smelting,sealing products,graphite moulds,continuous casting etc |

kinds of graphite moulds in continuous casting,precious metals smelting,glass,electronic industry,etc |

Semiconductor,photovoltaic, nuclear, aviation and aerospace |

Scientific research,atomic energy,nuclear reactor |

|

Size |

cylindric rods:Φ400x450mm, Φ450x450mm,Φ480x500mm, Φ500x600mm,Φ520x350/600mm, Φ560x500mm,Φ590x600mm, Φ610x520mm,610x600mm, Φ640x630mm,Φ680x650mm, Φ750x650mm,Φ810x700mm |

cylindric rods: Φ400x450mm, Φ450x450mm,Φ480x500mm, Φ500x600mm,Φ520x350/600mm, Φ560x500mm,Φ590x600mm, Φ610x520mm,Φ610x600mm, Φ640x630mm,Φ680x650mm, Φ750x650mm,Φ810x700mm |

cylindric rods:Φ400x450mm,Φ450x450mm, Φ480x500mm,Φ500x600mm,Φ520x350/600mm, Φ560x500mm,Φ590x600mm,Φ610x520mm, Φ610x600mm,Φ640x630mm,Φ680x650mm, Φ750x650mm,Φ810x700mm |

cylindric rods:Φ770x650mm,Φ700x650mm, Φ640x615mm,Φ565x525mm,Φ515x355/550mm, Φ410-470x800mm,Φ410x415/525mm,Φ470x415/525mm, Φ610x600mm,Φ640x630mm,Φ680x650mm,Φ750x650mm, Φ810x700mm |

|

Rectangular blocks: 400x400x400mm,400x400x500mm, 400x400x600mm,1000x500x290mm, 1300x500x300m |

Rectangular blocks: 400x400x400mm,400x400x500mm, 400x400x600mm,1000x500x290mm, 1300x500x300m |

Rectangular blocks: 400x400x400mm,400x400x500mm, 400x400x600mm,1000x500x290mm, 1300x500x300m |

Rectangular blocks: 1300x650x310mm,1300x510x410mm, 1000x410x330mm,1100x1100x310mm, 910x310x210/310mm,770x210x140/150mm |