| Prod Model: |

UL+Z-1600+255/14 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

Product Description

Application and composition

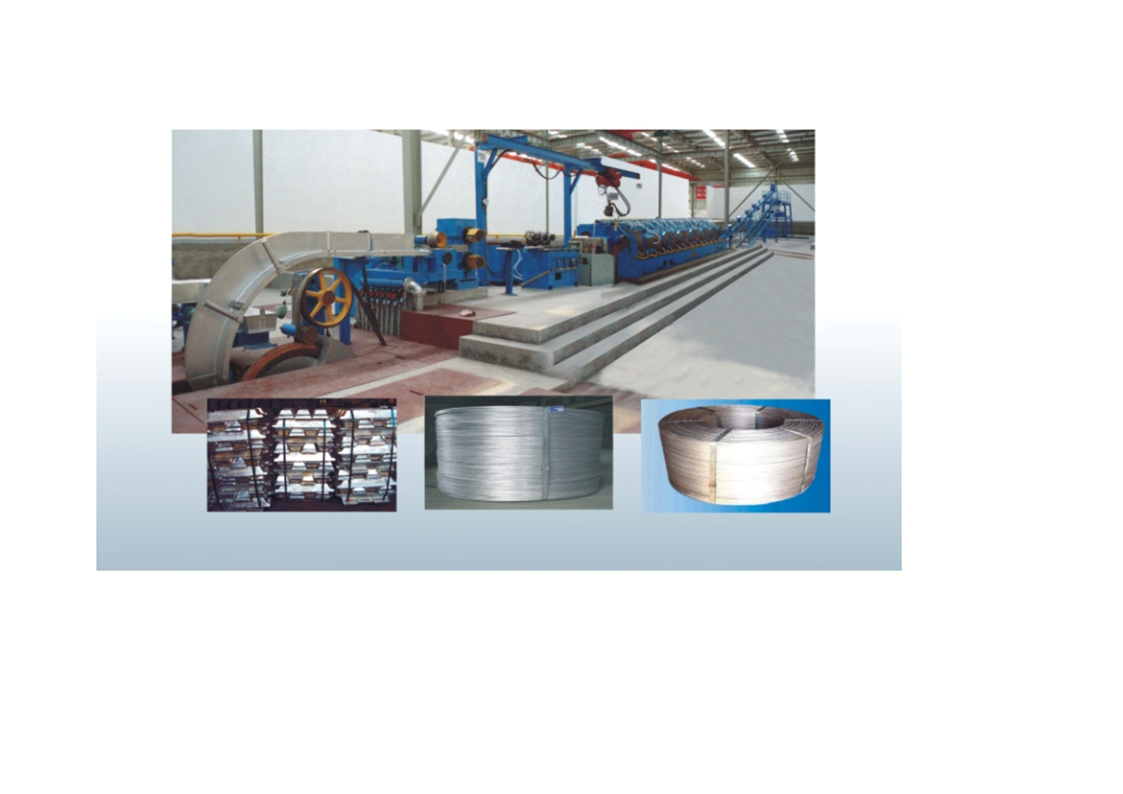

1. By means of continuous casting & rolling, this line works to produce diameter Φ 9.5mm or Φ 12mm pure aluminum rod, Al-Mg or Al-Mg-Si alloy aluminum rod with high conductivity.

2. It is mainly composed of a round shaped rapid energy-saving melting furnace with water-magnetic mixer, filtering and degassing device, five-wheel casting machine, roller shears, auxiliary hydraulic shears, motorized straightener, multi-frequency induction heater, rolling mill, oil lubrication system, emulsion lubrication system, quenching unit, coiler with two baskets and electric control system.

|

Main parts |

item |

specification |

|

Round shaped rapid energy-saving melting furnace |

Capacity |

2X12 t(Equipped with water-magnetic mixer) |

Filtering and degassing device

|

Degassing mode |

Degassing with inert gases through graphite rotor rotating and mixing |

|

Degassing capacity |

30~ 100kg /min |

|

Degassing efficiency |

50~70% |

|

Casting machine |

Casting wheel dia. |

1600mm |

|

Casting bar speed |

8~ 12m /min |

|

Casting bar section |

2300 mm 2 |

|

Roller shears |

Shearing length |

~ 700mm |

|

Motor |

15kw(AC) |

|

Motorized Straightener |

No. of straightening roller |

5 |

|

Power of motor for drive unit |

3kW |

|

Auxiliary hydraulic shears |

Max. shearing force |

14000kg |

|

Max. shearing stroke |

85mm |

|

Rolling mill |

Type |

Horizontal or vertical two-rollers stand for roughing rolling; Three-roller stand for finish rolling |

|

Outlet rod dia. |

9.5mm , 12mm |

|

No. of rolling stand |

14 |

|

Finished rolling speed |

4~ 6m /s |

|

Production capacity |

2.6~4 t/h |

|

Main motor |

355kw (DC) |

Quenching unit

|

Number of quenching box |

8 |

|

Temperature of outlet rod |

< 100ºC |

|

Consumption of cooling water |

50 m 3 /h |

|

Coiler with two baskets |

Drive speed |

7.5m /s |

|

Dia of coiling |

1400mm |

|

Motor for coiler |

4kw (AC) |

|

coiling basket |

1800mmX 1500mm |

|

Coil’s weight |

1500 -2000kg |

|

Multi-frequency induction heater |

Frequency of intermediate-frequency voltage |

350Hz |

|

Max. output power |

300kW |