Sh2500/9.5-255/ 14 Aluminum (Alloy) Rod Continuous Casting and Rolling Line

| Price: |

US $ 400000/Set |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T,Western Union |

1. Brief Introduction

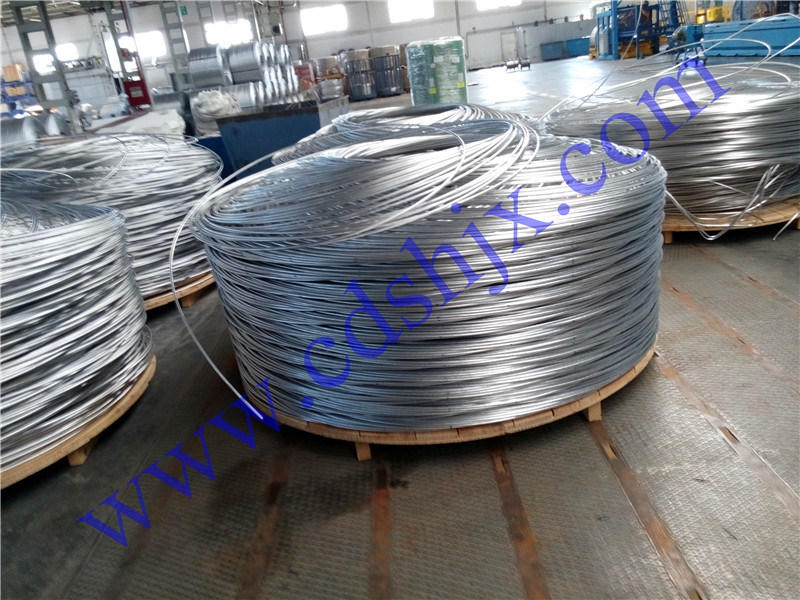

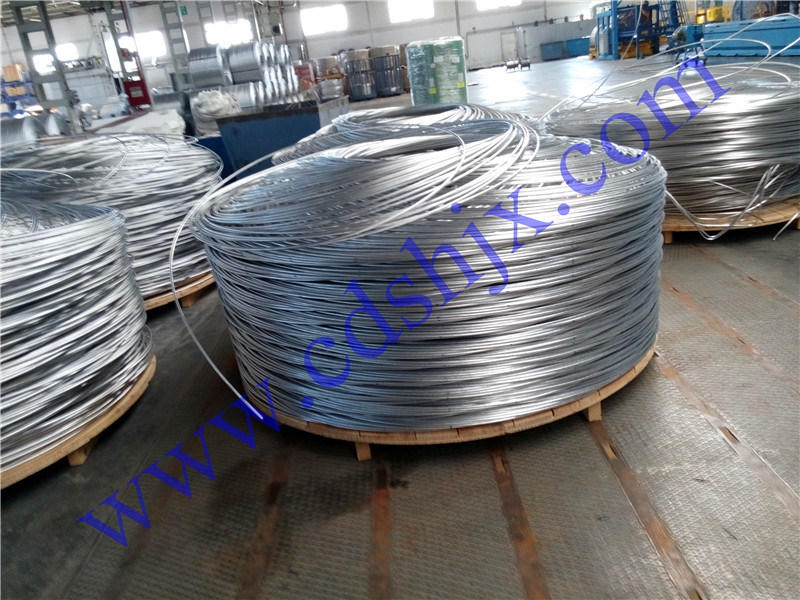

SH2500/9.5-255/14 aluminum (aluminum alloy) rod continuous casting and rolling line has our patent technology. There are many features as convenient dismantlement, high production efficiency, low energy consumption and good quality of aluminum (aluminum alloy) rod. It can produce aluminum rod and φ 9.5 mm aluminum alloy rod in the same situation.

It adopts process of continuous casting and rolling and produces aluminum (aluminum alloy) rod of 9.5mm from aluminum ingot with the casting sectional area of 2, 330 mm² . The raw material of aluminum rod is common aluminum ingot while the raw material of aluminum alloy rod is aluminum alloy ingot.

This line is composed of aluminum (aluminum alloy) refining furnace, (holding furnace), filtration device (the equipment mentioned above should be provided by the customer), Four-wheel continuous casting machine, ancillary, continuous rolling mill, quenching and collecting unit, oil emulsion cooling system, oil lubrication system and electrical control system etc.

2. Process Flow

2.1 Raw Material

Aluminum ingot and other elements required

2.2 Process Flow

Feeding, melting and refining- (holding furnace)-filtration system- launder-casting ladle-continuous casting (casting blank)-forward pulling-casting blank treatment unit (automatic shearer, ingot conveyer, straightening machine)-aluminum (aluminum alloy) bar induction heating-entering rolling mill (automatic feeding)-continuous rolling Oil refilling bag and leading duct Aluminum alloy rod quenching device-backward hauling-rod orbital coiler-finished product

2.3 Requirements for Production Circumstances

There are no special requirements for installation place. (Altitude, climate and environment)

3. Main Technical Parameters

| No. | Item | Specification |

| 1 | Casting Sectional Area | 2, 330 mm² |

| 2 | Aluminum (Aluminum Alloy) Rod Dia | φ 9.5mm |

| 3 | Production Capacity: ~for alloy 6201 | 3T/H |

| 4 | Rolling Speed | 7m/s |

| 5 | Height of Rolling Center | 902mm |

| 6 | Overall Dimensions of Main Equipment:(excluding aluminum melting furnace) | 40× 7.8× 5.1 m (L× W× H) |

| 7 | Overall Weight of Main Equipment | Approx. 83t |

| 8 | Power of Main Equipment | ~580KW+300KW (excluding aluminum melting furnace) |

| 9 | Compressed Air Volume | 5~6m m³ /h |

| 10 | Amount of Cooling Water (Soft Water) | 150 m³ /h |

| 11 | Amount of Emulsion | 170 m³ /h |

| 12 | Amount of Lubrication oil | (32#engine oil: 18 m³ /h) |

| Prod Model: |

Sh2500/9.5-255/ 14 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size: |

Customize |

| Certification: |

CE |

Chengdu Shuhong Equipment Manufacturing Co., Ltd (formerly Chengdu Shuhong

Machinery Corp., Ltd). is located in Qingbaijiang district of Chengdu, the beautifulland of abundance. The garden company was established in 1996, which is a self-R-D, manufacturing and mechatronics economic entity. The factory covers an area of 120, 000m2 with production workshops about 50, 000 m2. It owns various types of machining equipments, including floor-type CNC boring machine, vertical lathe, mill machine, planer, grinding machine, wire-electrode cutting, etc., lifting equipment such as 60T cranes, welding equipments, non-destructive testing equipments, and precision forging equipments.

Including: Two workshops 28313.10 m2

Office building 9479.50 m2

Stated Technology Center 4537.80 m2

Our company focuses on wire and cable equipments research and innovation, and becoming the leader of advanced technology in the industrialincreasingly. Depends on innovative technology, excellent products quality and thoughtful after-sales service, the copper/aluminum (alloy) rod CCR line with refining melting furnaces designed by Chengdu Shuhong have occupied about 80% domestic marketing share, products in the same industry in the country, even the first year sales. In the meanwhile, the products also have been exported to more than 20 countries and areas, including USA, Mexico, Turkey, India, Indonesia, Malaysia, Iran, Iraq, Syria, Algeria, Egypt, and Kazakhstan, etc., Chengdu Shuhong is a trusted partner for customers at home and abroad.

With years of rich service experience in the wire and cable industry, Chengdu Shuhong intakes the advanced technology from both domestic and overseas constantly, and has developed a series of new products to meet the full customer demand for unique personalized, such as: wheeL-belt type aluminum alloy ingot casting production line, 40-48t/h copper rod continuous casting and rolling line, 8t/h aluminum alloy continuous casting and rolling line, etc. The company has developed and produced of a grand total of more than 20 types products, including: non-ferrous metal rolling equipment, power cable equipment, submarine cable equipment, ferrous metal rolling equipment, environmental protection equipment, pressure vessel and so on. Chengdu Shuhong has got nearly 20 national patents and established the ISO9001: 2008 quality management system. ''SHUHONG'' is the provincial and municipal famous brand, China famous brand, and the main product has been promoted to be quality reliable products by China Electrical Equipment Industry Association.

Nowadays, Chengdu Shuhong has made great progress, and adhering to the concept of ''Innovation, professional manufacture, sincere service'', Chengdu Shuhong with full''enthusiasm and moving toward with a goal of becoming the world- leading electrical ''equipment manufacture. ''The chairman of company, Mr. Huang Hechang would like to invite all friends of different ''fields at home and abroad to our company, beautiful Chengdu city, and seek for mutual cooperation and together development.