We are manufacturing continues casting machine, continuous casting machinery, conticaster, metallurgy machine, CCM

We produce highly quality continues casting machine.

We are manufacturing continues casting machine, continuous casting machinery, conticaster, metallurgy machine, CCM

R6m, 3strands, 6meter billets

NO: R63L

I. Technical data

1. CCM

Casting radius: R6m

Billet specification: 125*125, 130*130, 150*150mm

Strand number: Strands 3 strands

Dummy bar: Rigid dummy bar

Ladle support: Ladle Rotor Tower

Cutting way: Automatic hydraulic cutting machines

Electrical system: Siemens Transducer, Siemens PLC, SCHNEIDER contactors. PLC automatic controlling

Billets Size: 6m

Pusher-type: Hydraulic pressure system, Mechanical car type.

2. Water system

A. Mould cooling water

Influent pressure: P≥ 0.9Mpfa

Influent temperature: ≤ 35c

Influent effluent temperature difference: 6-10c

pH: 7.5-9

Water total hardness: ≤ 150mg/L

Flow: ≥ 360Nm3/h

B. Secondary cooling water

Hydraulic: P≥ 0.6Mpa

Impurity particle size: ≤ 0.2mm

Flow: ≥ 80Nm3/h

C. Machinery cooling water

Hydraulic: P≥ 0.6MPa

Impurity particle size: ≤ 0.5mm

Flow: ≥ 60Nm3/h

3. Gas System

A. Oxygen

Pressure: P≥ 0.9Mpa

Purity: ≥ 99.5%

Flow: ≥ 4Nm3/min

B. Gas

Pressure: P ≥ 0.3MPa

Combustion value: ≥ 93700KJ/m3

Flow: ≥ 1.5Nm3/min

C. Compressed air

Pressure: P ≥ 0.5MPa

Flow: Q≥ 5Nm3/min

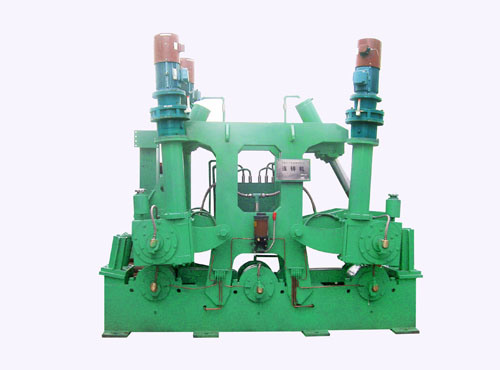

Withdrawal straightening machine

Power: 11KW

Rated revolution: 1500/min

Billet withdrawing force(max): 11000N

Straightening force (max): 220000N

Tension speed range: 0.3-3.0m/min

Dummy bar speed (max): 3.99m/min

4. Central hydraulic station

System pressure: P≥ 8.0MPa

System flow: Q=37.5L/min

II. Supply cope

1. On-line equipment list

No Equipment name Unit Qty. Remark

1 Ladle moving car PCS 2

2 Tundish moving car PCS 2

3 Tundish PCS 2

4 130sq. Mm mould PCS 3

5 Mould cover SETS 3

6 Oscillation device SETS 3

7 Secondary cooling manifold (stainless steel) and support SETS 3

8 Guide section for secondary cooling SETS 3

9 Steam drainage system in the secondary cooling system SET 1

10 Withdrawal straightening machine SETS 3

11 Dummy bar PCS 3

12 120sq Dummy head and transition head SETS 3

13 Dummy bar guide wheel SETS 3

14 Dummy bar storage device SETS 3

15 Dummy bar heat protetion cover PCS 3

16 Roller table before cutting Group 3

17 Transmit roller table Group 3

18 Discharge roller table Group 3

19 Transverse pusher SET 1

20 Cooling bed SET 1 Step by step

21 Overflow chute PCS 6

22 Hydraulic station system SET 1

23 Cooling water distribution system SETS 3

24 Electrical system SETS 3

A Power supply conbinet SET 1

B Frequency conbinet SETS 3

C PCL conbinet SET 1

D Main operating table SET 1

E Suspension operating box SETS 3

F Small operating box SETS 3

27 Steel structure platform Batch 1

A Main operating platform

B Temperature test platform

C Dummy bar storage platform

2\Auxiliary equipment

No. Equipment name Unit Qty. Remark

1 Water pipe, connector valve. etc Batch 1

2 Various cable, tube. etc Batch 1

3 Drainage gun PCS 3

4 Cutting gun PCS 3

3. Lead time: 100 days

4. Term of payment: 40% advance payment by T/T, 60% balance payment by T/T before date of shipment

5. Customer service: All the costs of seller's experts go and work at abroad for return air tickets, accommodation and meals, will be borne by the buyer. The buyer shall compensate the experts at USD 150 per engineer per day for debugging period. After normal operation the seller should be responsible to guarantee repair or change of the faulty components in 6 months, such as master control board, reactor, compensate capacitor, hydraulic device, breaker, and furnace shell

Delivery by 1 piece frame container, 1 piece 40HQ container, 5 pieces 40GP container.

Shanghai Electric Heavy Machinery Co., Ltd., Are affiliated company of Shanghai Electric Group Co., Ltd. (State company, turnover 100 billion USD We have been specializing in manufacturing, export and import electrical machinery, metallurgy equipment, turn key project for more than 50 years.

Our Main Products and Services

1. Metallurgy Equipment

Medium frequency induction furnace, houlding furnace, steel bar induction heating furnace, Ladle refinery furnace; Electric arc furnace(EAF, VD, VOD, ad/DC Eaf, vacuum electric arc furnace), Continues casting machine(CCM), rolling mills, vacuum furnace, cooling tower systems, dust collectors

2. AC / DC motors, pumps, vertical hollow shaft motor(VHS IEC strand and NEMA standard), vertical turbine pump, alternators/diesel generator sets, MW power generators, HFO (heavy fuel oil generator ) generators. Investment casting accessory; Insulation Materials

3. Office Products, Arts and Crafts products, hotel leather products, leather stationery.

4. Import and Export Agent or Purchase Agent/Office 2%-5% cost.

0UR products have been sold to and distributed in more than 50 countries and regions. SEMC(SMC) warmly welcomes customers from at home and abroad to further develop business relationships and partnerships for a prosperous future.