| Prod Model: |

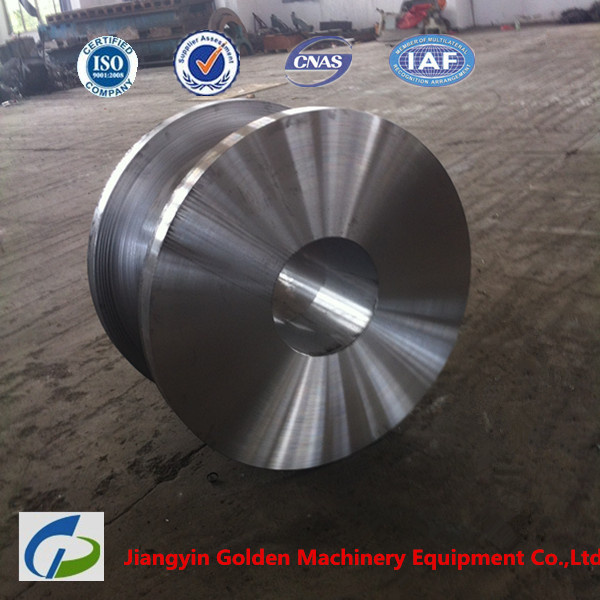

st52 lifting rope wheel |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size: |

300-1500mm |

| Color: |

Depend on Ral Table |

| Processing Object: |

Metal |

| Molding Style: |

Forging |

Product Description

Name: St52/Q345b high quality casted lifting rope wheel

SIZE: Ring forging/forged ring/annular forging/gear forging/steel sleeve/steel cylinder

| Diameter(mm) | Height(mm) | Single weight(kg) | Material |

| 800~3500 | 100~500 | 4200 or less | Carbon structure steel/alloy structure steel/low alloy steel/alloy steel/spring steel/stainless steel/heat resistant steel/high temperature alloy steel |

Standard: ANSI, JIS, BS, DIN, UNI, EN, GB, AWWA, API

Certification: ISO19001-2008, ISO14001:2004,GB/T28001-2001(OHS18001:1999)

Seamless Rolled Ring Forging Process

I. Upsetting

The ring rolling process begins with the upsetting of the starting stock on flat dies at its plastic deformation temperature.

II. Piercing

Piercing involves forcing a punch into the hot upset stock displacing metal radially and leaving a thin web of metal at the bottom.

III. Shearing

A subsequent operation, shearing, removes the thin web producing a completed hole through the stock.

IV. Preforming

This stock, referred to as a blank or preform, is now ready for the ring rolling process.

V.Forming

The doughnut-shaped preform is placed over the mandrel.

As the preform is rotated in the mill, the mandrel begins to apply pressure toward the main roll. At the same time, the axial cones apply pressure toward each other.

As a result of the radial and axial pressure, the ring's OD and ID gradually increase while the thickness and wall section are reduced.

forged seamless rolled rings used in

ball and roller bearings

power transmission

wind power gear ring

power generation

textile machinery

pulp & paper

pressure vessel

wind turbine bearing

steel fabrication

aerospace industries

products catalog:

Axial forging/ forged shaft

| Diameter(mm) | Height(mm) | Single weight(kg) | Material |

| 180~1000 | 500~8500 | 12000 or less | Carbon structure steel/alloy structure steel/low alloy steel |

| 180~650 | 500~6000 | 10000 or less | alloy steel/spring steel/stainless steel/heat resistant steel |

| 150~400 | 400~3000 | 10000 or less | high temperature alloy steel |

Ring forging/forged ring/annular forging/gear forging/steel sleeve/steel cylinder

| Diameter(mm) | Height(mm) | Single weight(kg) | Material |

| 800~3500 | 100~500 | 4200 or less | Carbon structure steel/alloy structure steel/low alloy steel/alloy steel/spring steel/stainless steel/heat resistant steel/high temperature alloy steel |

Module forging/forging block

| thick(mm) | width(mm) | Single weight(kg) | Material |

| 100~600 | 100~1600 | 18000 or less | Carbon structure steel/alloy structure steel/low alloy steel/alloy steel/spring steel/stainless steel/heat resistant steel/high temperature alloy steel |

Forging bars

| Diameter(mm) | Height(mm) | Single weight(kg) | Material |

| 80~650 | 16000 | 12000 or less | Carbon structure steel/alloy structure steel/low alloy steel |

| 80~650 | 16000 | 10000 or less | alloy steel/spring steel/stainless steel/heat resistant steel/high temperature alloy steel |

Forging discs

| Diameter(mm) | Height(mm) | Single weight(kg) | Material |

| 150~1000 | 100~500 | 4200 or less | Carbon structure steel/alloy structure steel/low alloy steel/alloy steel/spring steel/stainless steel/heat resistant steel/high temperature alloy steel |

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

Forging weight is from 50 kg to 20 ton. Many kinds of materials, free size.

Smelting Process: EF+LF + VD+VC The process as follow: Ingot → Heat → Forging → Heat treatment (Normalizing+ tempering) → Inspection → Rough machining→ UT → 2th Heat treatment → Finishing machining → Inspection

Applications: The heavy forging: Forged ring, shaft, roller, flange, or gear is widely used for various industries For example: Metallurgy, mining, power station and so on.

Specifications:

Description

The heavy forging: Forged ring, shaft, roller, flange, or gear

Material

Alloy steel or stainless steel

Material standard

ASTM or GB/T3077-1999

Specification

As per specified requirements

Weight

Max. 250 ton

Smelting Process:

EF+LF + VD+VC

Process

Ingot→ Heat → Forging → Heat treatment (Normalizing+ tempering) → Inspection

→ Rough machining→ UT → 2ND Heat treatment → Finishing machining → Inspection

UT standard

EN10228, ASTM A388 or JB/T 5000.15-1998

Competitive Advantage:

The heavy forging is manufactured by large scale stated enterprise. Advanced technical process from smelting steel to forging and heat treat guarantees the product quality. Closed relationship with several famous stated enterprises guarantee "in-time delivery" and competitive price.

Excellent product quality and service, competitive price, "in-time" delivery