| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Shaping Mode: |

Die-Casting Mould |

| Product Material: |

Polycrystalline |

| Product: |

Industry |

Product Description

All natural diamonds are strictly selected, grinded and polished by ourselves. The production of our wire-drawing dies is based on special technical processes, which result in slighter attrition of our high-quality wire-drawing dies. Also as outcome of these special technical processes, our tungsten carbide enameling dies are characterized to have surpassing leak-tightness. Furthermore, our extrusion tips and extrusion dies are famed for their extremely high concentricity and precision.

|

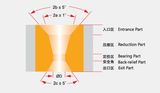

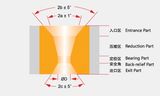

Reduction Angles & Bearing Length of Diamond Drawing Dies |

|

Area reduction |

Lead/ Zinc/

Argentine /Gold |

Aluminum / Nickel / Copper |

Brass / Bronze /Stainless steel |

High carbon steel |

Hot tungsten |

|

5-8% |

14° |

10° |

9° |

8° |

10° |

|

8-12% |

16° |

12° |

11° |

10° |

10° |

|

12-16% |

18° |

14° |

13° |

12° |

12° |

|

16-25% |

22° |

18° |

16° |

15° |

14° |

|

25-35% |

24° |

22° |

18° |

18° |

16° |

|

Bearing length |

0.2 - 0.5d |

0.3 – 0.8d |

Tolerance & Case of Diamond Drawing Dies

|

|

Diameter |

Tolerance |

Roundness |

Case |

|

inch |

mm |

mm |

mm |

mm |

|

≤ 0.0008 |

≤ 0.020 |

0.0006 |

0.0003 |

Φ 25× 6 |

|

0.0008 – 0.0019 |

0.020 – 0.050 |

0.0006 |

0.0003 |

Φ 25× 8 |

|

0.0020 – 0.0039 |

0.051 – 0.100 |

0.001 |

0.0005 |

Φ 25× 8 |

|

0.0040 – 0.0079 |

0.101 – 0.200 |

0.001 |

0.0005 |

Φ 25× 8 |

|

0.0080 – 0.0199 |

0.201 – 0.500 |

0.0015 |

0.0008 |

Φ 25× 8 |

|

0.0200 – 0.0399 |

0.501 – 1.000 |

0.002 |

0.001 |

Φ 25× 10 |

|

0.0400 – 0.0590 |

1.001 – 1.500 |

0.0025 |

0.0013 |

Φ 25× 12 |

|

0.0591 – 0.0866 |

1.501 – 2.200 |

0.003 |

0.0015 |

Φ 25× 14 |

|

0.0867 – 0.1299 |

2.201 – 3.300 |

0.004 |

0.002 |

Φ 28× 16

Φ 30× 16 |

|

0.1300 – 0.1810 |

3.302 – 4.600 |

0.005 |

0.0025 |

Φ 28× 18

Φ 30× 18 |

|

0.1811 – 0.2164 |

4.601 – 5.500 |

0.006 |

0.003 |

Φ 43× 26 |

|

0.2165 – 0.3150 |

5.501 – 8.000 |

0.008 |

0.004 |

Φ 43× 30 |

KINGTECH (KTC) MACHINERY GROUP Co., Ltd was founded in 1998, with the head center is located in the financial city of mainland China, Shanghai. Since the establishment of the company, we are professional in the machinery production and sales, here, KTC products include: metal sheeting processing, metallurgical equipment. KTC have 3 factories, with the metal sheet processing in the old capital city of China Nanjing, with metallurgical equipment in Shanghai and Xi'an. Shanghai Yaoli Electrical make Co., Ltd. Xi'an metallurgical equipment Co., Ltd; It is all belongs to the developed city with good transportation condition.