| Prod Model: |

AWS ECu |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Length: |

300mm-450mm |

| Diameter: |

2.5mm/3.2mm/4.0mm |

| Operating Current: |

International Standard |

| Welding Current: |

International Standard |

| Operating Temperature: |

International Standard |

| Application: |

Welding of Copper Structures |

| Packaging: |

5kg/Box 15kg/CTN |

| Delivery: |

25days |

| Certificates: |

CE, ISO |

| OEM: |

Is Acceptable. |

| Type: |

Cu (',Copper/Copper-Alloy Welding Electrode) |

| Material: |

Copper / Copper Alloy |

| Function: |

Gravity Electrode |

Product Description

The copper alloy brass (AWS ECu) belongs to cast iron electrode. Copper alloy brass wire meet AWS standard with CE, ISO and SGS certificates. Brass wire is used for welding copper structures and surfacing of marine corrosion carbon steel parts.

1. Details about the Copper and Copper Alloy Welding Electrode (AWS ECu)

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Ocean Welding

Model Number: ECu

Material: Copper / Copper Alloy

Length: 300mm-500mm

Diameter: 2.0mm,2.5mm,3.2mm,4.0mm

Application: All grades of castings, Pumps casing, gear housing, Engine

2. Specifications

Welding of copper structures and surfacing of marine corrosion carbon steel parts.

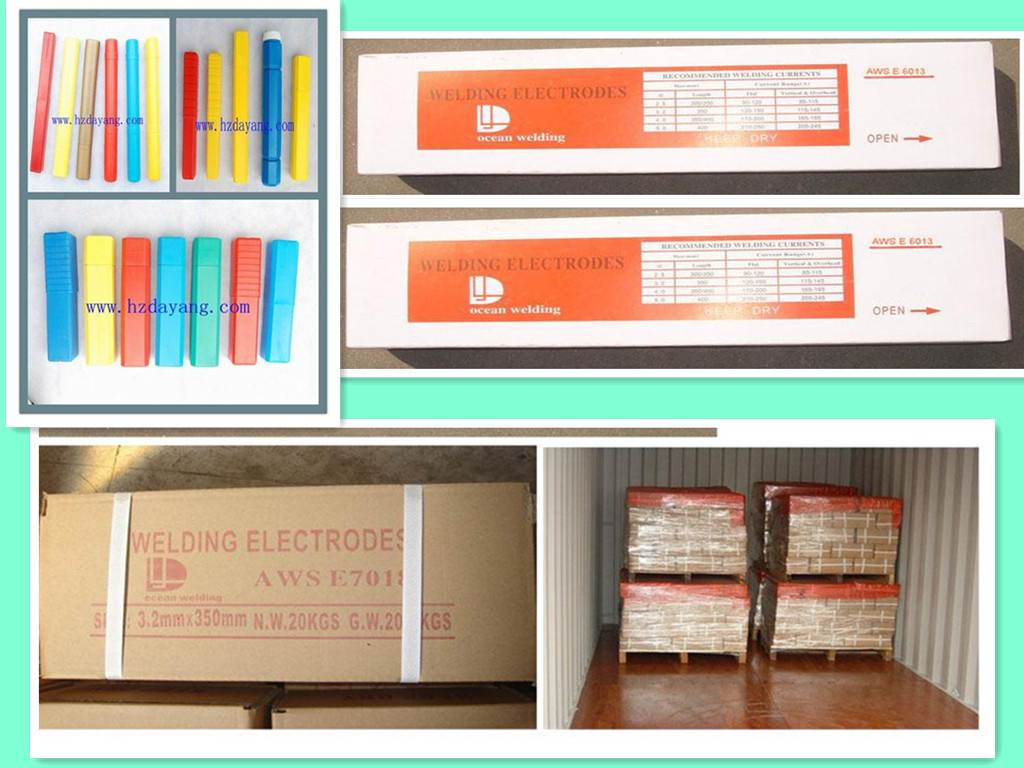

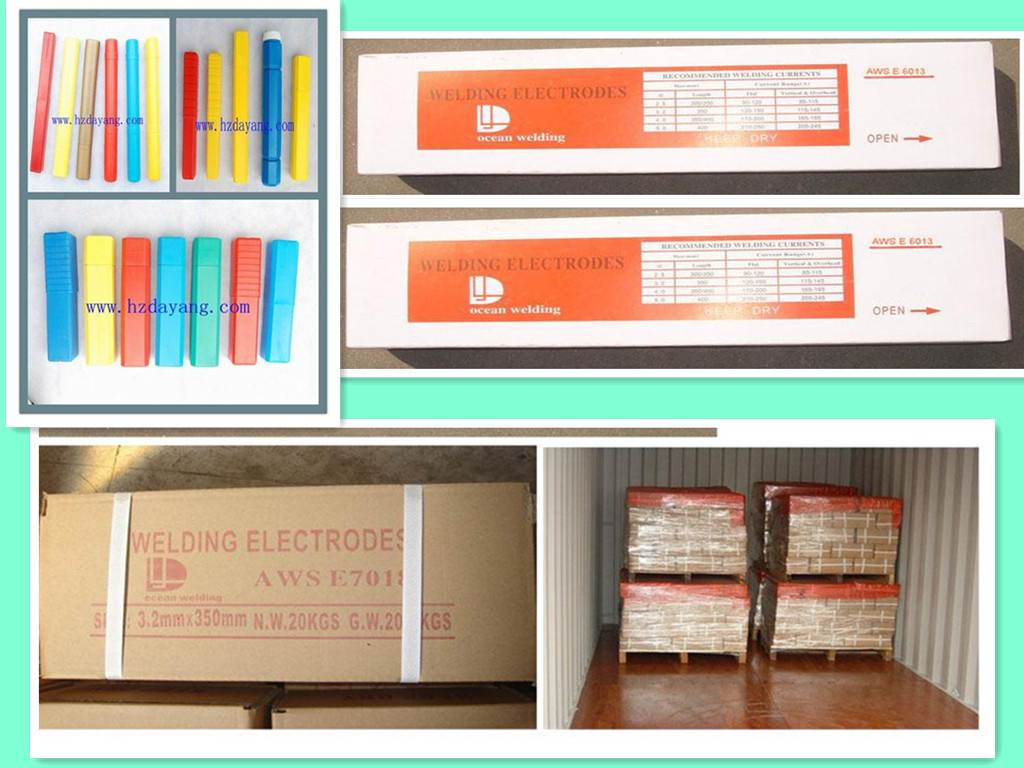

3. Packaging Details:

5kg/box, 20kg/carton

Delivery Detail: 20-25days

4. Our services

OEM is acceptable.

Samples are provided for free.Product Display

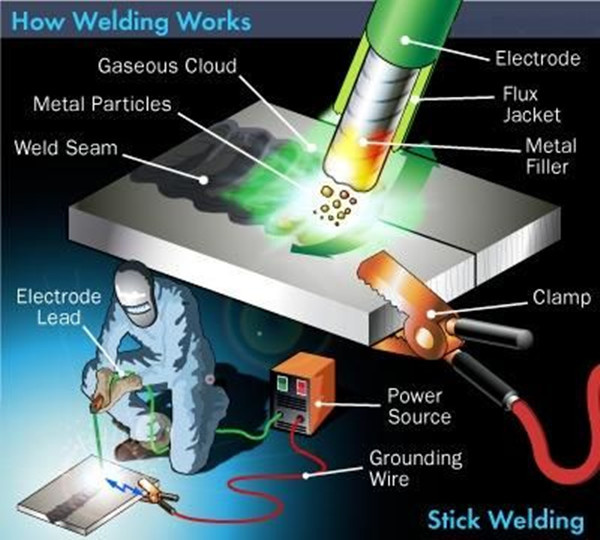

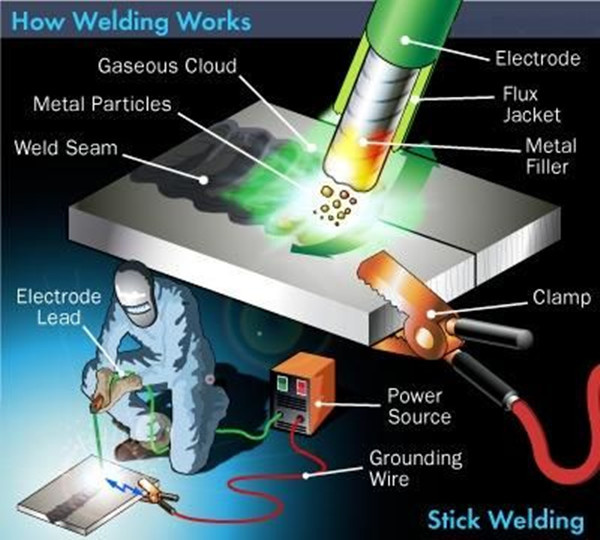

How welding works?

Package

Package

Company Information

Company InformationLin'an Dayang Welding Material Co., Ltd., located in the western part of Hangzhou, was established at the beginning of this century. We possess a production line of oil pressure unit, which can produce 5000 ton stainless steel welding electrodes. Our company owns rich technical resources to design, research and mainly produce special type of electrodes with complete models.

The electrodes are mainly exported and the amount is up to 2000 tons per year on average. Our customers are mainly from Germany, Indonesia, Singapore, Philippines, Vietnam, Thailand, Bengal, and Egypt. They think highly of our products all the time.

In the days of 21st century, we will be stricter with ourselves and have continuous technical innovation which will spur us on to higher quality products for our users. Customers at home and abroad are sincerely invited to visit, call and hold talks on internet.

|

Product Name |

Copper or Copper Alloy Electrode |

|

Product No. |

MHAE411-WE076 |

|

Standard |

|

GB |

AWS |

JIS |

DIN |

|

ECu |

ECu |

|

|

|

Type of Covering |

Low hydrogen Red copper core |

|

Welding Position |

F |

|

Chemical Composition of Deposited Metal (%) |

|

Chemical Composition |

C |

Mn |

Fe |

P |

S |

Si |

Pb |

Ti |

other |

|

Guarantee |

>95.0 |

≤3.00 |

_ |

≤0.30 |

_ |

≤0.50 |

≤0.020 |

_ |

Fe+Al+Ni+Zn

≤0.50 |

|

Mechanical Properties of Deposited Metal |

|

Test Item |

Tensile Strengh

Rm (MPa) |

Elongation

A4 (%) |

|

|

Guarantee |

≥170 |

≥20 |

|

|

Reference Current (DC) |

|

Electrode Diameter(mm) |

3.2 |

4.0 |

5.0 |

|

Welding Current(A) |

120-140 |

150-170 |

180-200 |

|

Instructions |

|

1.The Electrodes must be baked under 200 for an hour before Welding and used as soon as baking is completed. |

|

2.The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before Welding. |

|

Application |

Mainly for welding copper structures, such as conductive lugs, heat exchangers, and it could surface marine corrosive

carbon steel parts also. |

Hangzhou Lin'an Dayang Welding Material Co., Ltd., located in the western part of Hangzhou, was established at the beginning of this century.

It possesses a production line of oil pressure unit, which can produce 1600 ton stainless steel welding electrodes.

The company owns rich technical resources to design, research and mainly produce special type of electrodes with complete models.

The electrodes are mainly exported and the amount is up to 800 ton per year on average. The customers are mainly from Germany, Indonesia, Singapore, Philippines, Vietnam, Thailand, Bengal, Egypt, etc. and they think highly of our products all the time.

In the days of 21st century, we will be stricter with ourselves and have continuous technical innovation which will spur us on to higher quality products for our users.

Customers at home and abroad are sincerely invited to visit, call and hold talks on internet.

Package

Package Company Information

Company Information