| Prod Model: |

QC12Y |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Forging Forming Method: |

Tire Mold Forging |

Product Description

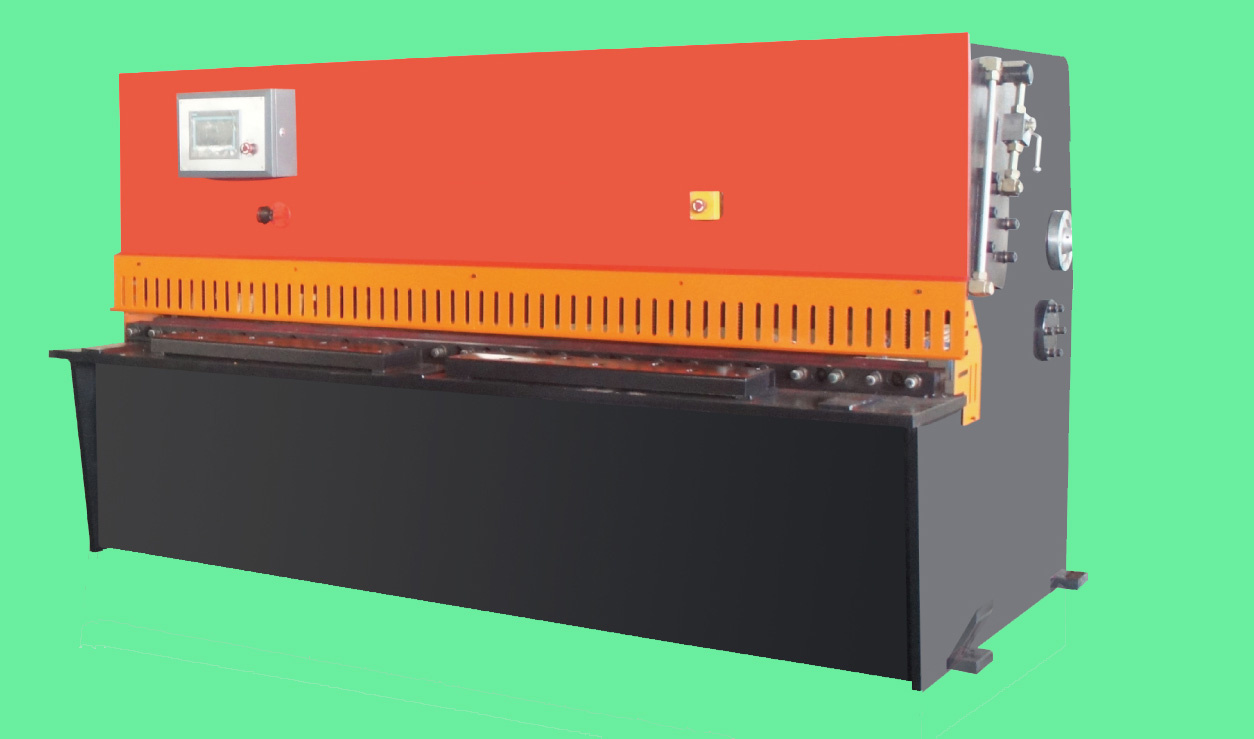

Features and Specifications of hydraulic cutting machine

1. The machine employs hydraulically-driven swing beam, the steel plate welded structure, and accumulator -based pullback cylinder with steady and reliable operation.

2. Indicator-based adjustment of gap of blade is convenient and fast.

3. The machine is equipped with lighting alignment device, and uses stepless control for the stroke of up tool carrier.

4. The machine uses protection fence for safe operation.

5. Digital display device for size of back gauge and shearing times available.

Main deployments of hydraulic cutting machine

1. NC controller: E10S NC System

2. Main motor: Siemens Germany

3. Major Low voltage electrical: Schneider France

4. Gear pump: Boschrexroth Germany

5. Seal ring: Valqua Japan

6. Hydraulic system: Boschrexroth Germany

| Model | Shear angle(°) | Strokes(min-1) | Back gauge(mm) | Main motor(KW) | Dimension (mm) |

| L | W | H |

| 4×2500 | 1.5 | 14 | 20-500 | 3 | 3200 | 1650 | 1620 |

| 4×3200 | 1.5 | 14 | 20-500 | 5.5 | 3900 | 1650 | 1620 |

| 4×4000 | 1.5 | 12 | 20-500 | 5.5 | 4700 | 1900 | 2000 |

| 6×2500 | 1.5 | 18 | 20-500 | 7.5 | 3200 | 1650 | 1620 |

| 6×3200 | 1.5 | 14 | 20-500 | 7.5 | 3900 | 1650 | 1620 |

| 6×4000 | 1.5 | 12 | 20-500 | 7.5 | 4700 | 1850 | 1700 |

| 8×2500 | 1.5 | 14 | 20-500 | 7.5 | 3200 | 1650 | 1620 |

| 8×3200 | 1.5 | 12 | 20-500 | 7.5 | 4000 | 1650 | 1620 |

| 8×4000 | 1.5 | 10 | 20-500 | 11 | 4800 | 1800 | 1700 |

| 10×2000 | 1.5 | 18 | 20-800 | 11 | 2630 | 1800 | 1700 |

| 10×2500 | 1.5 | 10 | 20-500 | 11 | 3200 | 1800 | 1700 |

| 10×3200 | 1.5 | 10 | 20-500 | 18.5 | 3900 | 1950 | 1900 |

| 10×4000 | 1.5 | 8 | 20-800 | 18.5 | 4700 | 2200 | 2100 |

| 12×2500 | 1.75 | 11 | 20-600 | 18.5 | 3200 | 2127 | 2235 |

| 12×3200 | 1.75 | 10 | 20-600 | 18.5 | 3900 | 2127 | 2235 |

| 12×4000 | 1.75 | 8 | 20-800 | 18.5 | 4700 | 2250 | 2100 |

| 16×2500 | 2.5 | 8 | 20-600 | 18.5 | 3200 | 2400 | 2100 |

| 16×3200 | 2.5 | 7 | 20-600 | 22 | 4000 | 2400 | 2100 |

| 16×4000 | 2.5 | 6 | 20-800 | 22 | 4700 | 2500 | 2300 |

| 20×2000 | 2.75 | 7 | 20-800 | 37 | 2700 | 2330 | 2520 |

| 20×2500 | 2.75 | 6 | 20-800 | 37 | 3200 | 2100 | 2750 |

| 20×3200 | 2.75 | 5 | 20-800 | 37 | 3900 | 2350 | 2750 |

| 20×4000 | 2.75 | 4 | 20-800 | 37 | 4800 | 2400 | 2750 |

| 25×2500 | 3 | 5 | 20-800 | 37 | 3500 | 2400 | 2500 |

| 25×3200 | 3 | 4 | 20-800 | 37 | 4000 | 2400 | 2500 |