| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Process: |

Open Die Forging |

| Processing Object: |

Metal |

| Molding Style: |

Forging and Machining |

| Molding Technics: |

Normalizing+Annealing+Quenching+Tempering |

| Certification: |

API/Q1 |

Product Description

Products with Customers' Designs - Strong Machining & Heat Treatment Abilities - Strict Quality Control - Prompt Delivery

We are a reliable supplier that can make forging parts and casting parts. Here are some details of the products for your reference.

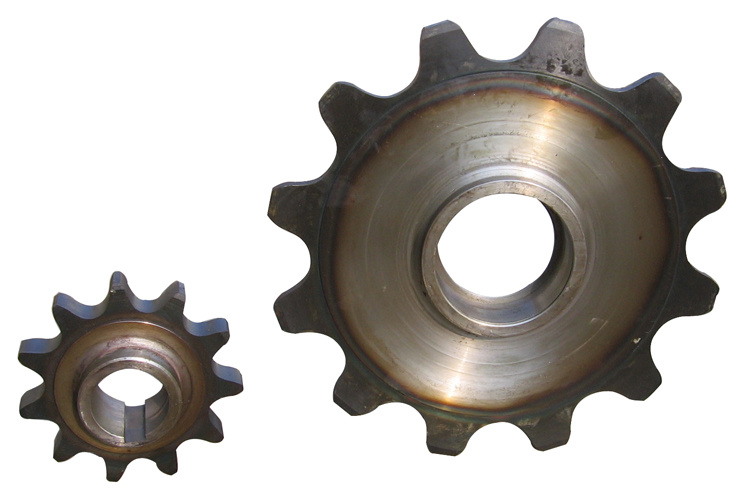

1. Main products: Custom Open Die Forging, Main Shaft, Wind Power Shaft, Stabilizer, Flange, Coupling, BOP Body, Tube Plate, Roller Forging, Roller Shell, Ring Forging, Gears, Gear Blank, Gear Shaft, Gear Wheel.

2. Materials: Carbon steel, Alloy steel

3.Supplying range: Shafts, Sleeves, Rings, Cylinders, Blocks, Modules etc

4. Process: Forging/Casting - Normalizing & Tempering - Proof Machining- Quenching & Tempering - Finish Machining

We can offer you in various process conditions.

5. QA DOC.: Chemical Composition Report, Mechanical Properties Report, UT Report, Heat Treatment Report, Dimensions Check Report

The data on chemical composition report and mechanical properties report are approved by third party, Luoyang Ship Material Research Institute, CSIC.

UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.

Heat Treatment Report: provide original copy of heat treatment curve/time table.

Steel Ingot: EAF-LF-VD/ESR. Material Certificate according to En10204-3.1 is requested from ingot supplier.

6. Specifications of Forging:

Shape | Diameter(m) | Length(m) |

Shaft | ≤2.5 | ≤15 |

Block | ≤4.0 | / |

Ring | ≤4.9 | ≤3.5 |

Cylinder | ≤1.5 | ≤8.0 |

7. Standards: GB, JIS, AISI, SAE, ASTM/ASME, EN, DIN, GOST

8. Certification: ISO9001: 2000, CCS

9. OEM and Customized service offered

Hongfeng can provide the products with the single weight up to 11mt and diameter up to 3m, such as tube sheets, rings, cylinder and shafts, etc. The material includes Austenitic stainless steel, Martensitic stainless steel, Duplex Stainless Steel, Carbon steel and Alloy steel. Their products widely used in transmission, mould, metallurgy, petrochemical, valve, shipbuilding, and cars. Our company has more than 18years experience, with the ability to provide a series service of blanking, heating, forging, heat-treatment, CNC, inspection, surface-treatment, packing and shipping.

Since establishment, Hongfeng develops year by year; The main equipments are as below: 1 set for each 11mt & 5mt electro-hydraulic hammers, 1set for each 3mt, 1.5mt, 1mt and 750kgs air hammers; 5 sets of gas heat furnaces; 3sets of electrical heat treatment furnaces; 2 sets for each 16mt&10mt and 4sets of 5mt cranes; 5 sets of Large sawing machines ( the sawing length up to 3m), 12sets of common sawing machines; 4sets of vertical lathes(¢ 3m*2.5m), 3sets of 10m*¢ 1.4 and 8sets of 1m*¢ 800mm horizontal lathes. The production capacity can reach 20000mt; The products are strictly according to the standard. From the beginning to the end of every order, we have detailed records for every process.