| Prod Model: |

FM-25 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Method: |

Hydraulic Pressure |

| Processing: |

Brick Production Line |

| Product: |

Brick |

| Brick Raw Material: |

Cement |

| Type: |

Construction Machine |

Product Description

Foam Concrete Machine FM-25 FM-25 is professional equipment for foam concrete.

1. StructureFM-25 includes four parts, a belt conveyor, a mixer, a pump and a built-in foam generator inside the pump. The equipment is easy to install, dismantle, transport, and construct at site. The equipment has been fully debugged in factory. After assembling the three parts and hose, it is ready to use after plug the power.

2. Features1) Dual-cylinder hydraulic propelling system with high discharge pressure, the machine can pump to high rise building floors. It reduces labor intensity.

2) Raw material input ratio is semi-automatic; therefore, foam concrete density is only a button press process.

3) Siemens motor and superior quality parts, guaranteed stable quality;

4) Domestic and overseas training services available

5) Superior quality foaming agent, low construction cost.

6) Flexible mobile and positioning ability with wheels,

7) Unique pump head, easy to dismantle and clean

8) 1000 L mixer and high power motor, fast mixing and large output. Unique mixer blade design, no damage to the foam. Saves foaming agent dosage while enhancing foam concrete quality.

9) It is applicable for both making foam concrete products and on-site casting.

10) 80 meters long casting hose, saves labor cost and reaches high rise building casting needs.

11) It is capable of casting foam concrete with sand content. Cheap sand reduces production cost.

12) Convenient design, decent paint and appearance.

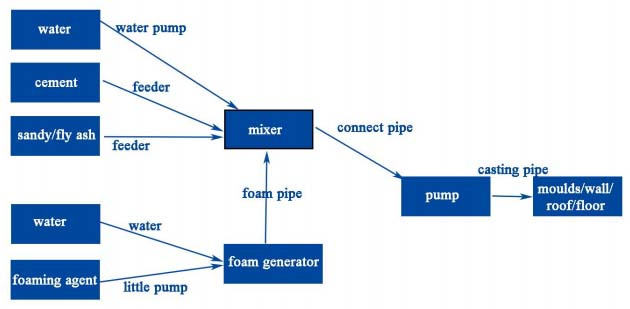

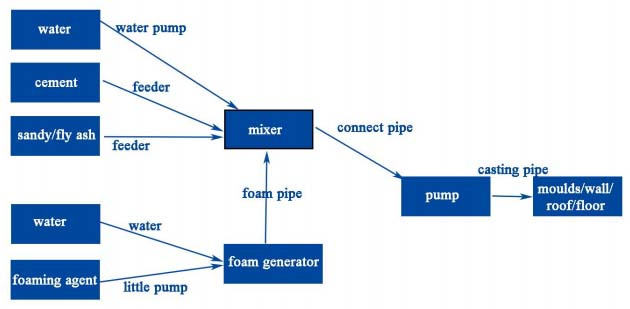

3. Work Flow  4. Application Area

4. Application AreaFloor/roof casting

Block

Wall panel

Framed wall and house structure casting

Subway and coal mining backfill

5. Technical Parameter:

Term |

Unit |

FM-25 |

Power |

kw |

30 |

Max. Productivity |

m3/h |

25 |

Vertical Delivery Distance |

m |

150 |

Horizontal Delivery Distance |

m |

500 |

Pumping Pressure |

Mpa |

5 |

Dimension (L*W*H) |

mm |

3800*1500*1500 |

Weight |

kg |

1800 |

Trinity Construction, a foam concrete machinery manufacturer and solution provider, is mainly engaged in foam concrete Total Solution machine, foam generator, foam concrete mixer and foaming agent research and fabrication. Its products had been exported to over 20 countries and areas, such as Australia, Canada, Vietnam, Honduras and the Middle East.

Adhering to the principle of "Pragmatic and exquisite, " it actively improves the product quality and service. The employees are dedicated and dependable, always ready to serve each customer with a warm pre-sale, sale and after-saless attitude, eager to supply you with a product that fits your needs.

Trinity Construction is a member of China Foamed Concrete Association and China Internaitonal Chamber of Commerce. Trinitt foam concrete machine had got six patents, and first company to get CE identification.

Now we use new technology and skills for machines, quality is better, types is more modernization.