Zinc & Aluminum Die Casting Mold

| Price: |

Negotiable/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

500/Piece |

| Pay Type: |

L/C,T/T,D/P,Paypal,Money Gram |

Due to metal aluminum and the aluminum has is good of liquidity and plasticity, and casting processing is in has pressure of die-cast machine in the casting, so aluminum die-cast can made various more complex of shape, thereby aluminum die-cast was widely application Yu car manufacturing, and engine production, and motorcycle manufacturing, and motor manufacturing, and pump manufacturing, and drive machinery manufacturing, and precision instruments, and gardens landscaping, and power construction, and building decorative, all industry.

| Product Description |

| Material | Aluminum alloy, A360, A380, ADC12 |

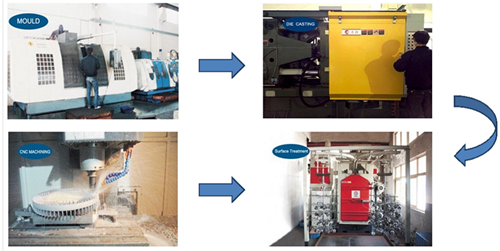

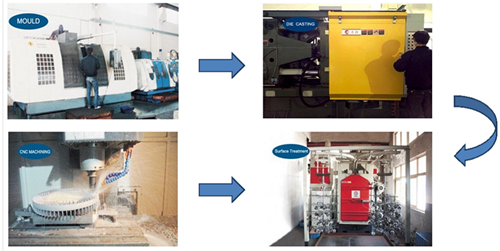

| Process | Mould, casting, Machining |

| Finish | Polishing, chorome/nickel/zinc plating, electroplating, painting, |

| Powder coating, anodizing, electrophoresis, sandblasting |

| Lead time | 30-50days |

| Software | Pro/E, AutoCAD, SolidWork2001, UG, CAM |

| Machine | CNC Machining Center, Die Casting Machine, CNC Lathe, CNC Milling Machines |

| Laser engraving machine |

| Testing Equipment | ROSH X-ray Analyzer, Precision roughness Tester, Salt spray Tester, |

| Electroplating thickness gause, Spray equipment |

| Certification | ISO19001 |

Contact us

We want to know:

1.What's the product you make

2.The product size and weight

3.Your special requirement

We will recommend you reasonable injection machine,make you max.benefit is our dream.

Thank you for your patient.

Smart Tech E Limited

Web:www.smartmoldtech.com

| Prod Model: |

D1607890 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Place Of Origin: |

Shenzhen, China |

| Mold Base: |

Lkm |

| Product Material: |

Aluminium Alloy ADC-12, ADC-12; A360, A380 |

| Tolerence: |

0.01mm-0.03 |

| Mold Material: |

718, 8407, S136, P20, Kd-61, Nak80 |

| Mold Life: |

10k-1000k |

| Mechanical Drawing: |

Step, Iges, Stl, Solidworks Ects |

| Product Surface Treatment: |

Color , Silk Screen, UV/Rubber Coating Ects |

| MOQ: |

500-1000 |

| Material: |

Aluminum |

| Surface Preparation: |

Oxygenation |

SMARTTECH is a plastic mold and molding company, based in HongKong with branches in GuangDong province. Our company is market oriented. We have machines and Secondard Operation process as below:

Plastic Injection centers

Injection machine: 60 sets.

EDM and wire cutting machines.

Vacuum forming machines.

Low-pressure injection molding machines.

CNC machining centers.

CNC milling centers.

Ultraviolet UV ovens.

Painting, silkscreen, electroplating, anodizing and other surface treatment facilities.

We can also carry on small batch production and a large scale of injection model appearance on painting

SMARTTECH is a leader in the domestic business field and is also highly competitive within many international markets. ShenZhen company was founded in May, 2006. Meanwhile, we are further developing international sales branches in ShenZhen and DongGuan. The development team has increased not only the number of staff but also the significant skill base. These include professional quotation operators, designers, figure file operators, and also several sales representative's fluent in English, Japanese, French, etc. Providing the most professional relative service for the clients all over the world. Many industrial design and rapid prototyping companies from South Korea, Japan, India, Canada, United State, United Kingdom, Norway, Czech, Slovakia, Ausralia, New Zealand have established long-term business relationship with SMARTTECH.

SMARTTECH is also a professional one-stop R&D engineering service provider, not only we were formed by a group of people who owned many years of practical R&D and manufacturing experience, but also we have the resource of special equipments and instruments for prototype PCBA making, testing and analyzing, product mechanical-structure prototype and tooling service, this will be a great help for your R&D departments, and increase the speed and effectivity for your new product development. Our service includes Product R&D prototype engineering service and added-value R&D engineering service.

We operation complies with ISO9001 quality system instruction and requirements since Oct, 2008. SMARTTECH designing has invested in advanced technologies and highly skilled work force. With these assets, we can model out of a very wide variety of materials including many sorts of plastic such as ABS, MABS, PMMA, PVC, PC, POM, PP, PA, PPT, PE, etc. Of course the same is true for as many metals including stainless steel, aluminium and copper.

Why choose us:

Standing at the forefront of the wireless communications industry, smartflair wins its customers with its rich experience and expertise in bluetooth, GPS, uwb, zigbee and other wireless communications related fields.

Strong ODM and OEM service capability proved and continually strengthened by international cooperation practices.

Flexible and effective business performing ability supported by a well-integrated internal management system.