1) Material: Zamak 3, Zamak 4, Zamak 5 etc, according to customers' requirement;

2) Product weight from 0.02kg to 5kgs

3) Process: Die Casting + Machining

4) Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing

5) Surface Finish: Chrome plating, Zinc Plating, Sandblasting, Powder Coating...

6) OEM/ODM parts range: Auto parts, electronic parts, motor shell, pump parts, machinery Parts, light fittings, dental equipment, medical cases etc and other industrialuses

7) Applied software for specification drawings: PRO/E, auto CAD, solid work, CAXA, UG, CAD/CAM/CAE

8) Products shown on the website are OEM/ODM produced; For reference use only

Specific Zinc Die Casting Capabilities:

Automated equipment can handle high volume casting jobs of up to 100, 000 pieces per week

Manual machines for low volume jobs of as little as 500 pieces per year

Can cast from 0.02 to 5kgs

Single to Multiple Cavities

6 Sets of hot chamber die casting machines range from 88 tons to 280 Tons

Most zinc die casting alloys are offered such as Zamak 2, Zamak 3, Zamak 5, Zamak 7, ZA8, ZA27 etc

Specializing in Small, Big, Complex, Precision components

State-of-the-Art Cast Finishing

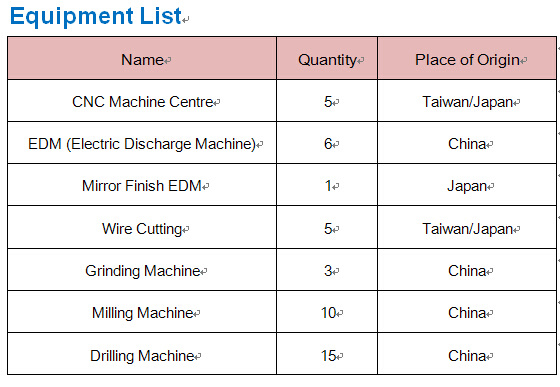

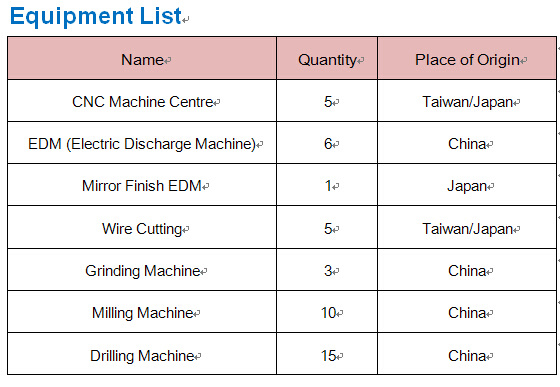

The STK facility offers a complete in-house, independent machining facility with the latest CNC mills and lathes to provide fully machined castings. Our sanding and surface finishing capabilities include:

Shot blasting

Parting line removal

Chrome Plating

Nickle Plating

Zinc Plating

Powder coating

Painting

PVD

We believe that the best way to ensure our success is by providing our customers consistent quality in a timely fashion and at a fair price.

Stick Industry was established in 2004, with factory located in Haicang district, Xiamen city, South East of China. The company has been in business for over 10 years, beginning as a small plastic mold and die casting mold workshop growing into an industrial leading, multi-plant molder with factory size over 10000 square meters and employees about 150.

Conveniently located in the south of China, our ISO 9001-2000 Certified facility economically services markets throughout the world including USA, Russia, Canada, Mexico, Brazil, Germany, Spain, Italy, Poland etc

In addition to outstanding growth in our die cast and injection molding department, our secondary machining operations have continued to grow to meet the varied needs of our customers, including: Drilling, tapping, turning, boring, milling, sanding, shot blasting, vibratory finish, and more.

From concept to final production, from mechanical and electronic design to components sourcing, and from prototype manufacturing to mold design, our engineer team can jump in at any stage to complete your valuable project on time.

Our service include: Moulds, plastic injection molding, Aluminum/Zinc Die casting, CNC Machining, Sheet Metal Forming, Surface Treatments, Assembly and packaging.

We will pay great attention to your any question or enquiry.

If any questions, please feel free to contact us at any time.

Tel: 86-592- 5209671

Fax: 86-592- 5209672

Ms. Anna Lin

Website: Www. Stickindustry. COM / www. Mould-casting. COM

Automated equipment can handle high volume casting jobs of up to 100, 000 pieces per week

Automated equipment can handle high volume casting jobs of up to 100, 000 pieces per week