Item: Worm Transmission Soft Sealing Gate Valve (Z545X-10/16Q)| DN | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 |

| L | 457 | 508 | 660 | 720 | 780 | 840 | 960 |

| Hmin(full close) | 1480 | 1665 | 2200 | 2800 | 2800 | 3000 | 3000 |

| Hmax(full open) | 1650 | 1900 | 2350 | 2950 | 2950 | 3150 | 3150 |

Feature of Soft Sealing Gate Valve1. Flat bottom, less dust accumulated, flow smoothly, switch easily.

2. Surface is coated with EPDM, no water or rust corrosion. Connected well with the board, not easy to drop off, and with good flexibility memory. Reliable sealing, anti-wear and no leakage.

3. Internal and external of Valve use nontoxic coating resin, enhance decay resistance capability, eliminate the second polluton to water.

4. The seal design uses three O-rings, which can make replacement and maintenance during water supplying.

Our Advantages:1. High quality material, more resistant to moisture and open-air environment.

2. Hand wheel surface thermal spaying epoxy resin powder coating, good looking and easy for cleaning, corrosion-resistant, perfect combination with valve life.

3. Copper Parts use HPb59-1 bar by forming multi-channel hot forging process, not annealed after forging, dense and weather resistance, no cracking, no internal stress.

4. Seals of EPDM rubber, water aging performace, life int he water longer than the NBR, guaranteed for 50 years.

5. Rubber vulcanization using advanced technology to ensure that iron is not exposed, don't contact water, no rust.

6. All valve flow cavity use heat pure epoxy powder coating, with small flow resistance. Pass 1500KV spark test, no rust, effectively prevent the second pollution from cast to water.

Our Production Process

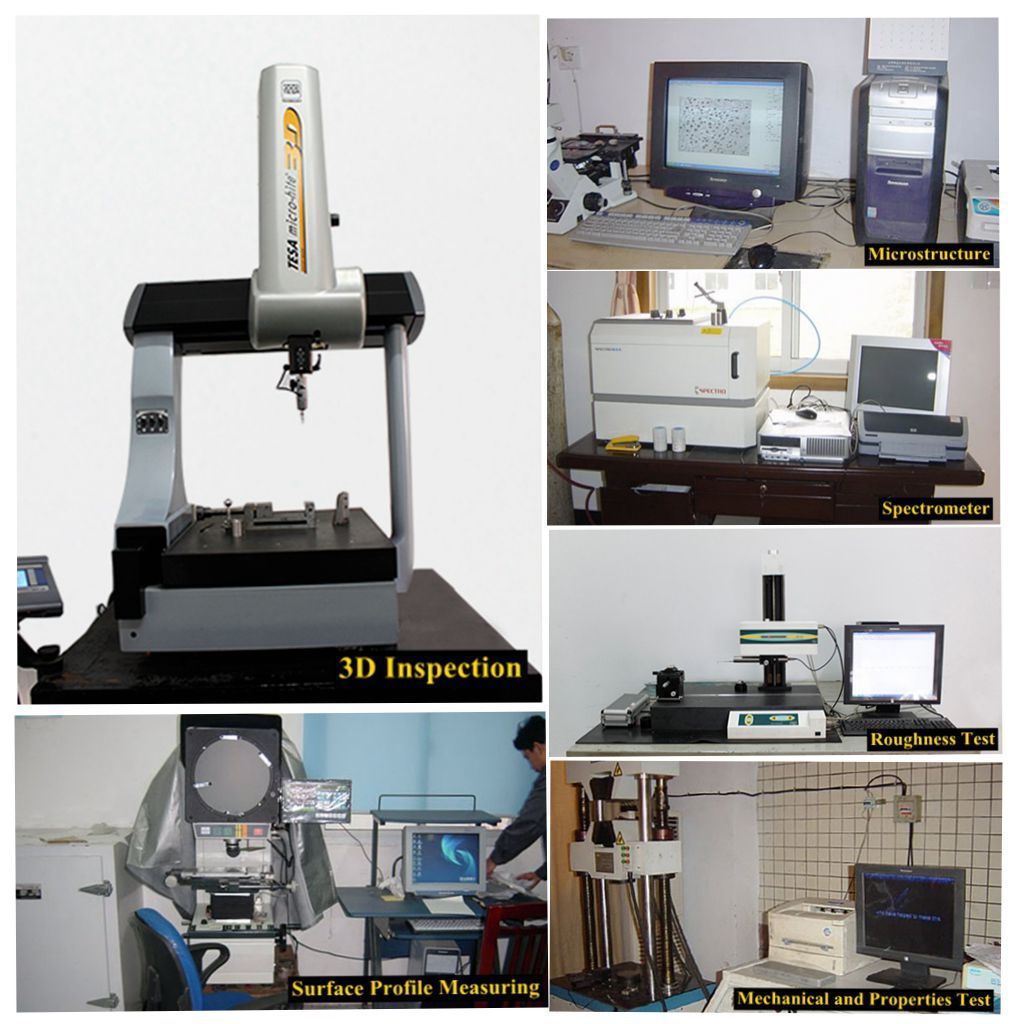

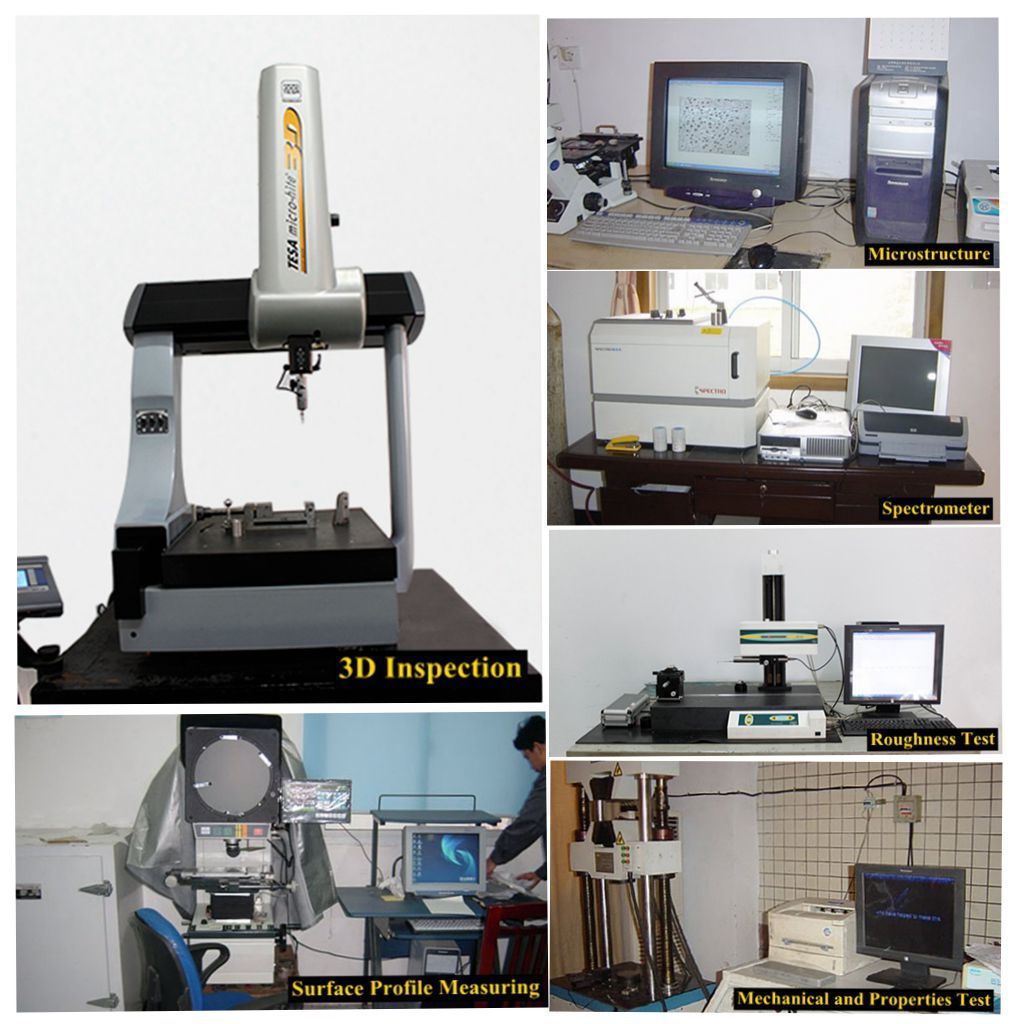

Our Quality Control

Our Quality Control

Our Customers

Our Customers

Changzhou East Foundry Technology Development Co. Ltd (EFT) was founded in Changzhou, China in 1993. At the beginning it was a technical service department of China Foundry Association, a group of high level foundry experts provided the technical consulting & technical service for foreign companies who wanted to buy castings from China and for local companies who wanted to sell castings abroad. EFT started to specialize in processing and exporting castings in 1999.

Mr. Qin Furu, the founder of company, engaged in foundry industry for 50 years, is expert consultant for China Foundry Association.

As a leading provider of high-quality casts and precision-machined parts, we offer One-stop Shopping with competitive solutions for all casting needs. Our wide selections have attracted big-name buyers from the United States, the United Kingdom, Germany, etc, in the construction, mining, auto-fitting and water supply industries. Our primary materials are copper alloy, aluminum alloy, stainless steel, alloy steel, grey iron and ductile iron.

Our factory is equipped with CNC machining centers, CNC lathes, drilling machines, and a variety of quality testing instruments. Supported by over 20 years' experience in casts manufacturing and exporting, we could ensure you high-quality products and timely delivery.

Our Customers

Our Customers