1.Product Name: wind power turbine shaft

2.Processes: Investment casting, Lost wax casting, Precision casting,Water glass casting, Silica sol casting, Sand casting, Furan resin sand casting

3.Material Range:Steel,S355,S355J2G3,ST52,ST52-3,Q345,Q235,NM360,Hardox 400,Hardox 500,SS304,SS316,etc.

4.Certification system : ISO 9001 Registed;Strict material inspection;Exact dimension control;100% quality control

5.Prompt quote & Lead time guarante:30 -40 days

6. Application Fields: Ship,Construction, Industry, Train,Excavator etc

7.Payment Term: T/T, Sight L/C,etc.

8. Trade Terms: FOB Ningbo or Shanghai,China, CIF xx etc

9.Material Standard: ASTM, AISI, ASME, SAE,NF EN, DIN EN, ISO, BS EN, SS, etc.

Software for Specification Drawings: PDF, JPG, Auto CAD. Pro/E, Solid works,

10.Inspection Equipment: Spectrograph, Tensile Strength Test Machine, Impact Test Machine, Rockwell Hardness Tester, Brinell hardness Tester, Leeb Hardness Tester, Vickers Hardness Tester, HX-MIAS, Magnetic Defect Detector, Ultrasonic Flaw Detector, X-Ray Test.

11.Machining Equipment: 3150Ton hydraulic machine, 1Ton&2Ton & 5Ton& 8Ton Drop forging,CNC Machining Shop, Lathe, Milling Machine, Drilling Machine, Boring Lathe, Grinding Machine, Heat Treatment Furnaces.

12.Dimension Inspection: Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge, three coordinates measuring instrument.

13. Packing: Wood Carton, Cardboard carton, or according to customers' requirements.

14.Surface Heat Treatment: Quenching, Oil Quenching, Water Quenching, Normalizing, Temper,Annealing,etc

15. Annual Output: 8000-10000 Ton

16.Export Markets: Australia wind power turbine shaft,America,United States. U.S.A. wind power turbine shaft, Canada wind power turbine shaft; U.K. England, Britain wind power turbine shaft,Germany wind power turbine shaft,France wind power turbine shaft ;Italy wind power turbine shaft,Espana,Spain wind power turbine shaft, Holand wind power turbine shaft,South Africa wind power turbine shaft;Danmark wind power turbine shaft; Sweden wind power turbine shaft Finland wind power turbine shaft ;Belgium wind power turbine shaft; Romania wind power turbine shaft; Russia wind power turbine shaft; Brazil wind power turbine shaft; Argentina wind power turbine shaft .

17.Supplier:China Ningbo wind power turbine shaft factory; China Ningbo wind power turbine shaft company; China Ningbo wind power turbine shaft co.,ltd; China Ningbo wind power turbine shaft inc; China Ningbo wind power turbine shaft corporation; China Ningbo wind power turbine shaft manufacturer; China Ningbo wind power turbine shaft Supplier; China Ningbo wind power turbine shaft part; China Ningbo wind power turbine shaft foundry

18.If you are interested in our products, please do not hesitate to contact us.

19.Nord Engineering Machinery Co.,Ltd is a very good wind power turbine shaft supplyer ,who can produce all kinds of wind power turbine shaft according to your drawings or samples.We has been engaged in producing wind power turbine shaft for many years. Our goal is to provide great prices on quality items while providing excellent service to our customers.We sell wind power turbine shaft to all over the world,our customers are always satisfied with wind power turbine shaft quality. High production rate assure low production cost.No matter what kind of wind power turbine shaft you need,just contact us,we can quote a favorable price for you.Don't hesitate,let us put our expertise to work for you.

Ningbo Yinzhou Nord Machinery Co., Ltd. is a compositive strength company, engaged in different fields of parts manufacturing. Now we successfully own three subsidiaries, they are Parfect Casting Limited, Parfect Forging Limited & Parfect Engineering Machinery Co., Ltd.

Casting parts are made by Lost-wax, Lost-foam, sand-casting, Investment casting and precision casting process, such as spares of the pumps, mining equipments, construction machinery, and transportation equipments like trains & ships.

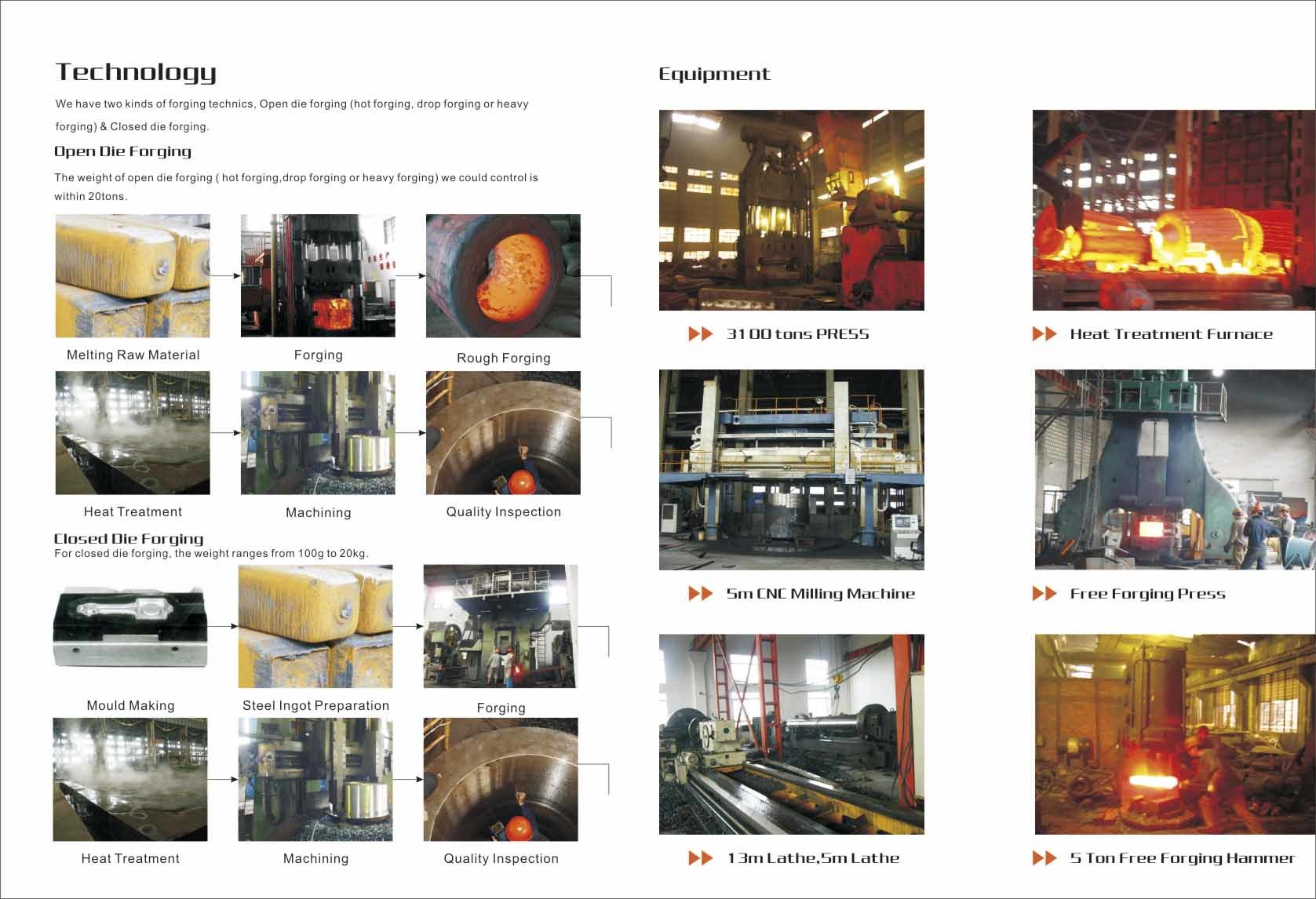

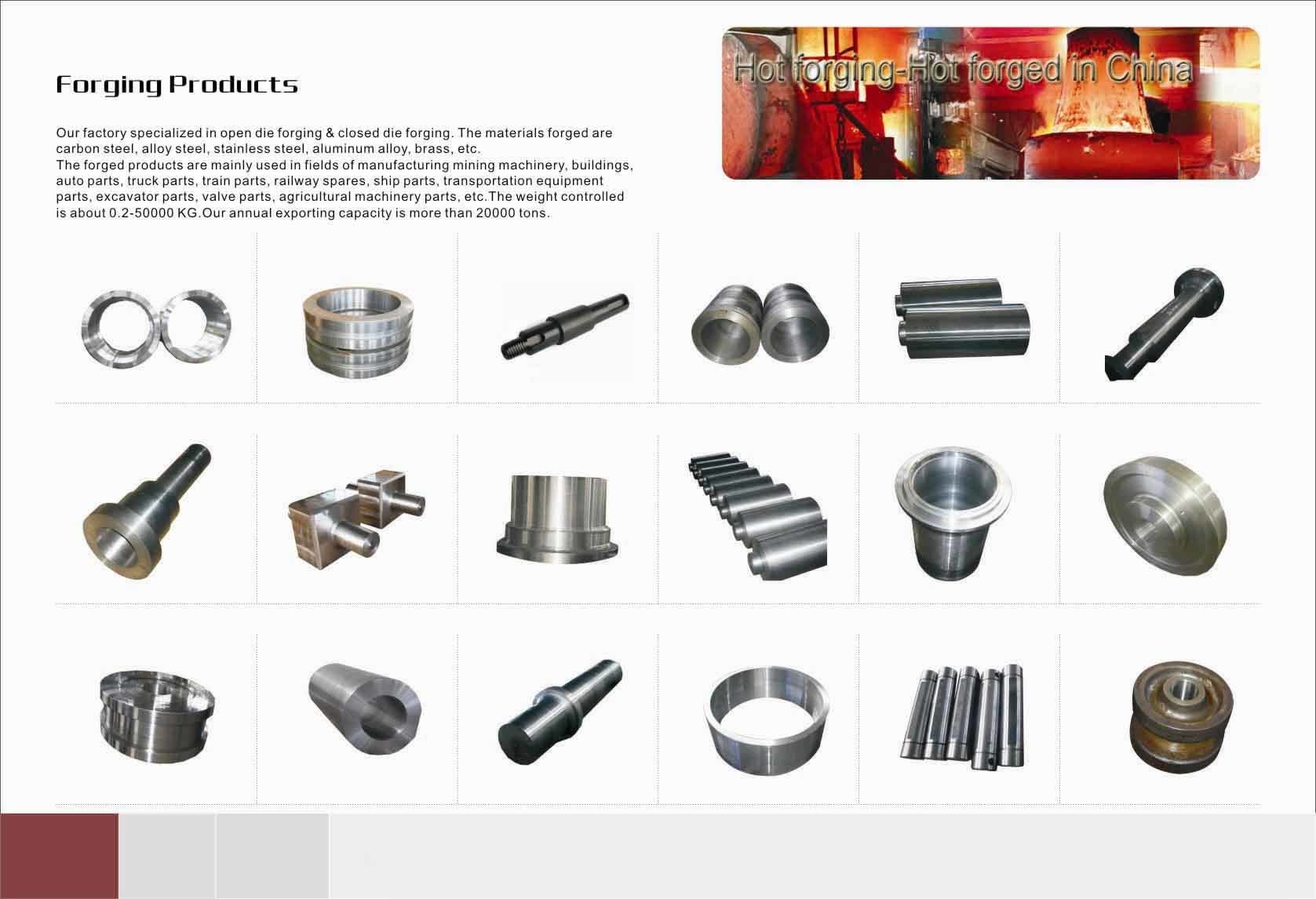

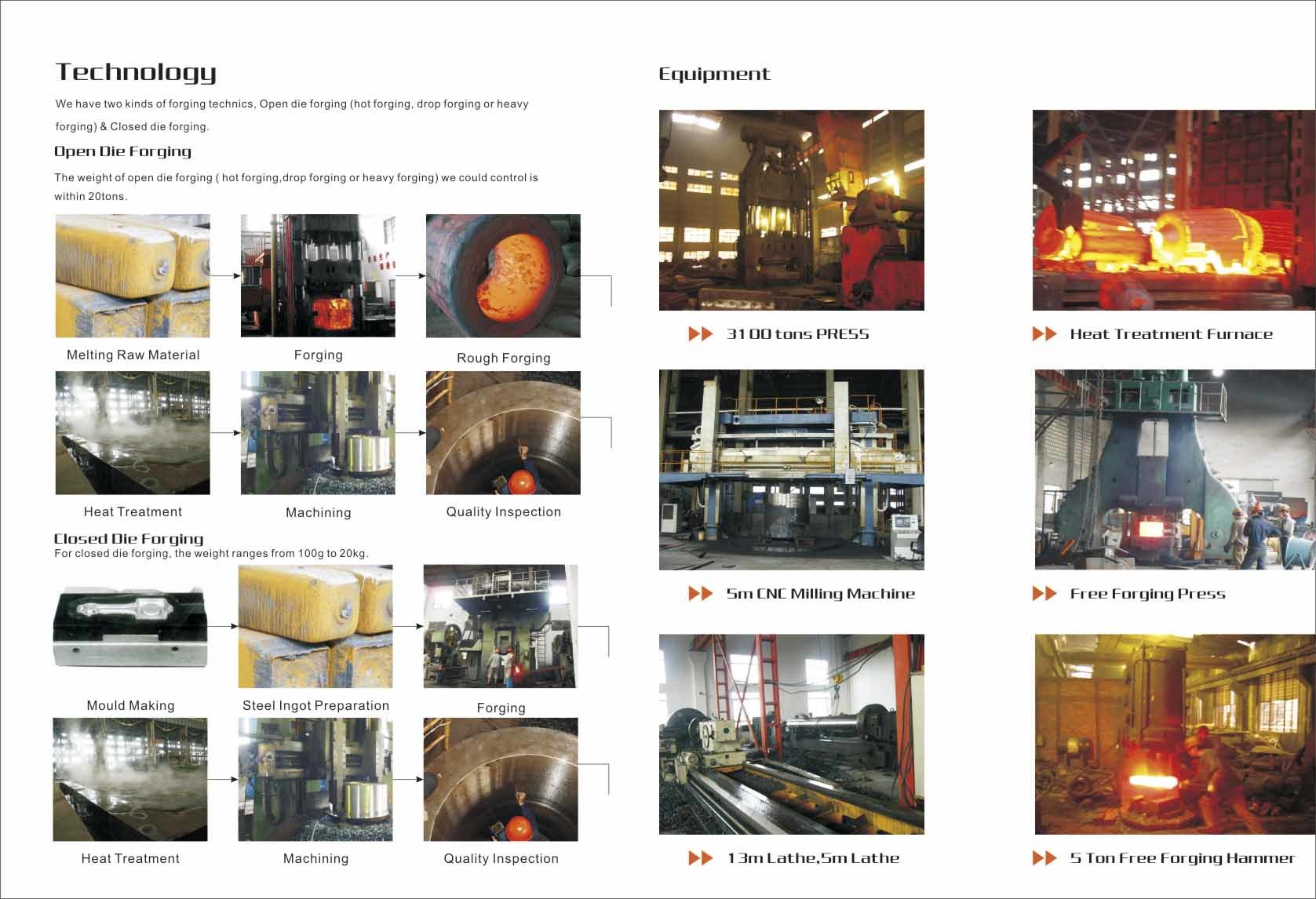

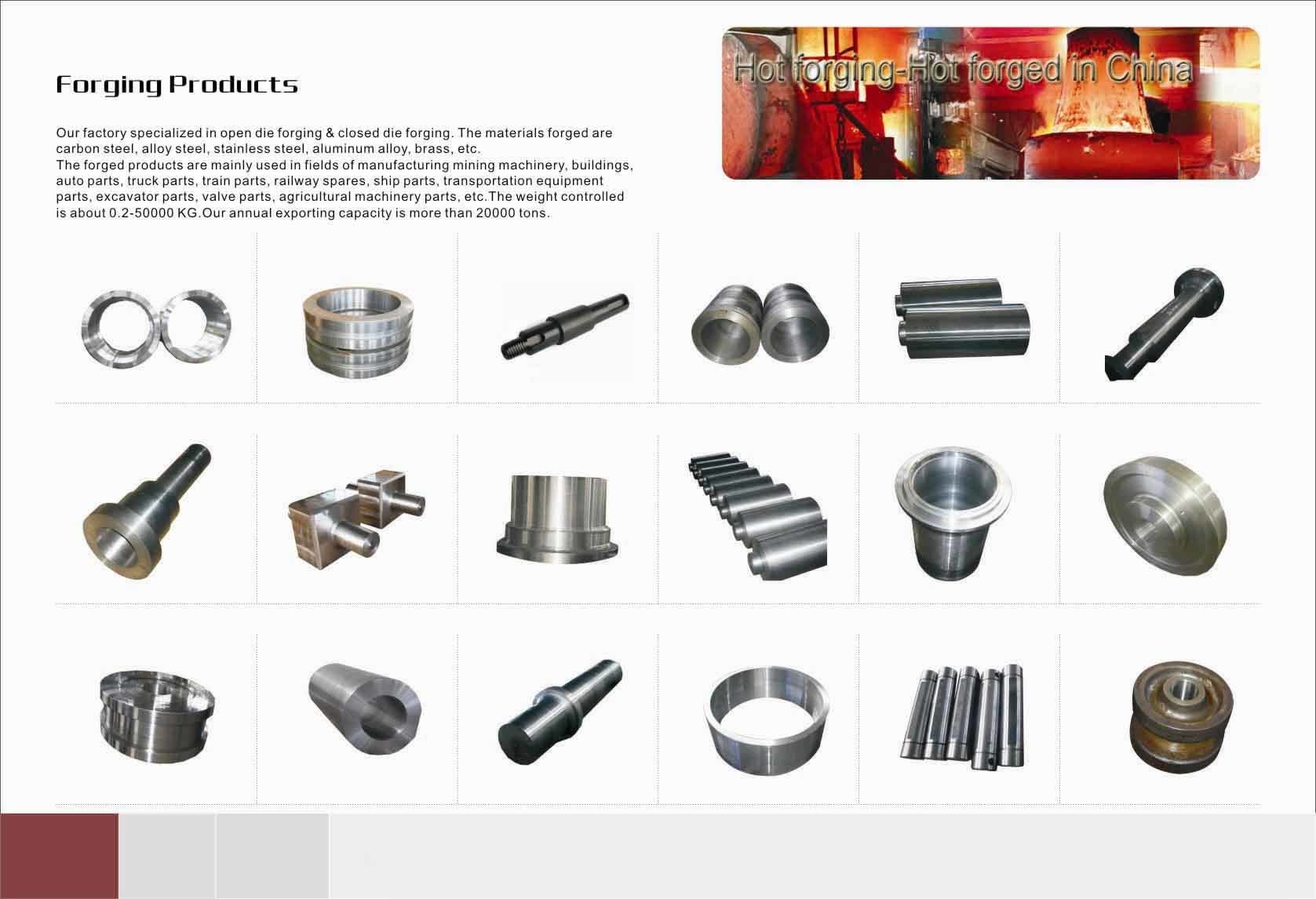

Different sizes of forging parts are made by open die forging & closed die forging, they are for mining equipment, shipbuilding, Engineering machine, oil & power transportation equipment.

Our welding capacity is best, we produce different kinds of excavator buckets, all kinds of metal weld fabricaton and a range of bucket attachments.

Please view our website, where you will find more information about our company and products.

ITEM: China investment casting/Sand Casting/Iron Casting

Our main product covers all kinds of gray iron casting, ductile iron casting and Vermicular cast iron casting, which wildly used in auto, train, texilty, printing machine and so on.

1, Product details as bellow:

2. Material:

Carbon Steel, Alloy Steel, Stainless Steel, Tooling Steel

3. Material Standard:

ASTM, AISI, ASME, SAE, NF EN, DIN EN, ISO, , BS EN, SS, etc.

4. Items:

FOB Ningbo or Shanghai, China

5. Lead time:

30~40 days

6. Place of origin

Ningbo, China

7. Software for specification drawings:

PDF, Auto CAD, Solidworks, JPG, ProE, etc.

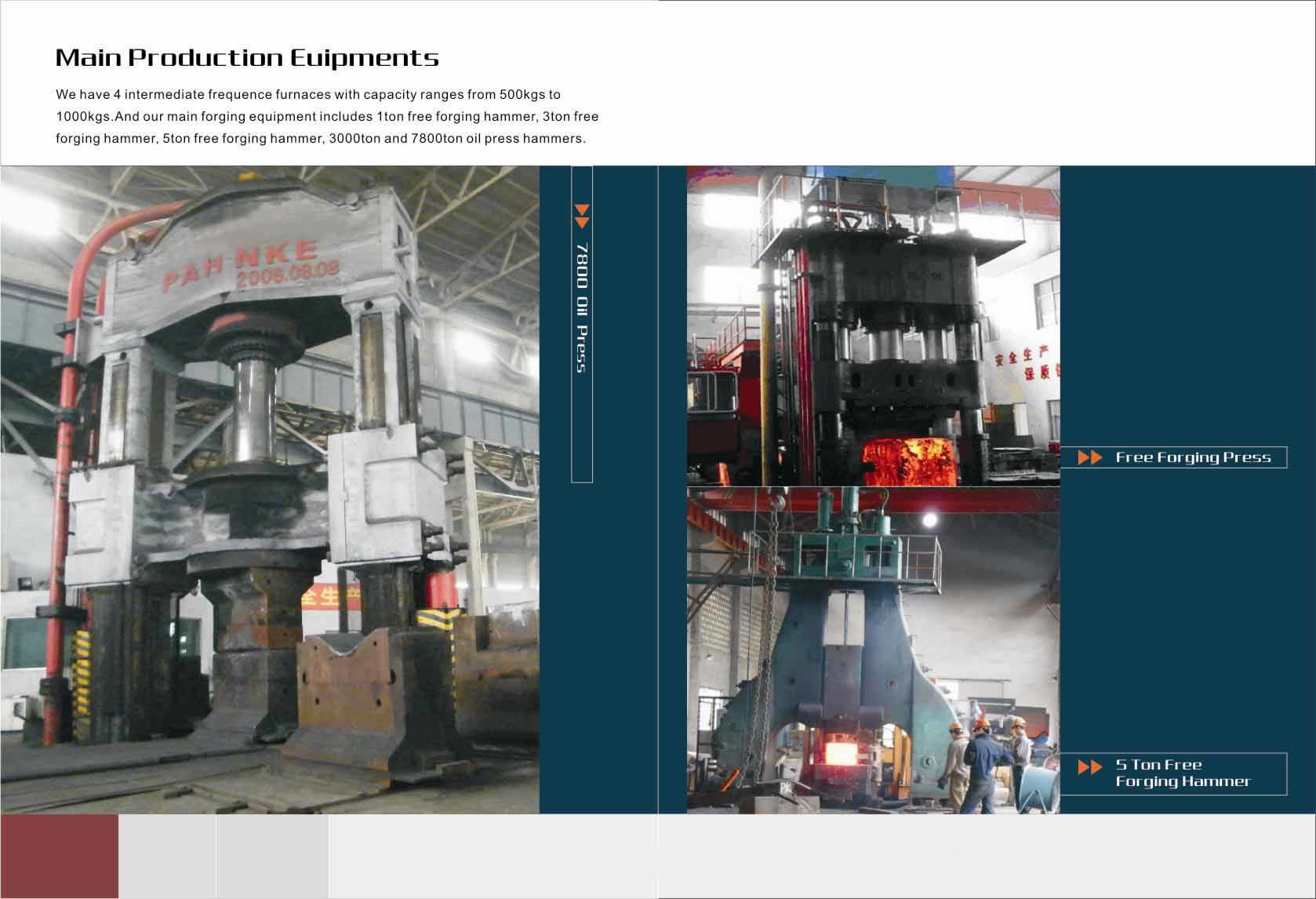

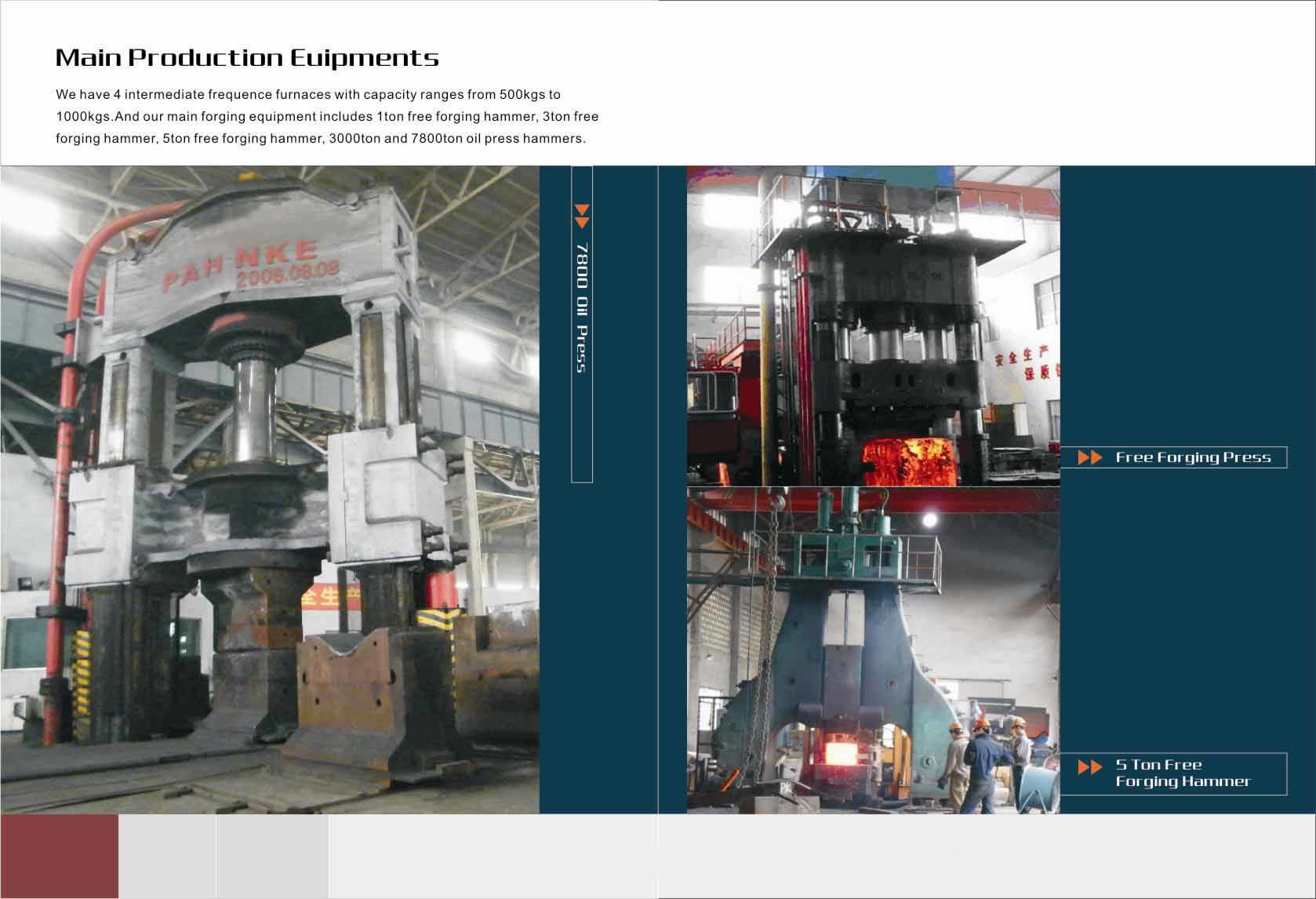

8. Main production equipments:

2 set of 1 ton forging hammer, 1 set of 3 ton forging hammer, 1set of 5 ton forging hammer, 1set of 3000ton and 1 set of 7800ton oil press hammers, CNC-machine-center, Lathe, Milling machine, Drilling machine,

Boring Lathe, Grinding Machine, Heat treatment Furnace.

9. Heat Treatment Machine:

Mesh-Belt-Furnace, Carburizing Quench Furnace, Chamer Furnace, etc.

10. Surface Treatment:

Cold/Hot Zn Plating, Blackening Treatment(Salt Spray Test 48-96 hours), Ni Plating,

Cr Plating, Spraying Undercoat, Anti-Rust Paint, Surface Paint, Plastic Paint,

Coated Anti-Rust Water, Anti-oil, etc.

11. Surface Heat Treatment:

Medium Frequence Quenching, High Frequence Quenching and Carburizing and

Quenching, Oil Quenching, Water quenching, Normalizing, Temper, Annealing, etc.

12. Dimension Inspection:

Calipers, Height Laugue, Micrometer Calipers, Inside Caliper Gauge, Angle

And R Gauge, Three coordinates measuring instrument.

13. Productivity:

50000 PCS / year

14. Packaging:

Wooden package after mandatory treatment or other

15. They are using for steamship mining equipment, Construction equipment,

Agricultural equipment, Train, Truck and others.

16. We make Open die forging and Closed die forging in Ningbo, China

If you have any other question, please feel free to contact us.