1. Multiple changes of immerged nozzles the product can quickly change immerged nozzles for several times during the online pouring of tundish, enabling the continuous pouring by one tundish for several furnaces.

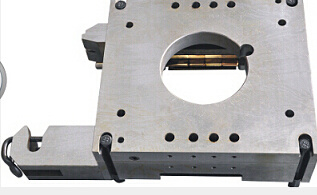

2. Instant change of immerged nozzle without stop of continuous casting the product can change an old immerged nozzle with a new one within 1.5sec during the online pouring of tundish.

3. Change of immerged nozzle without lifting the product can quickly change an immerged nozzle without lifting the tundish during its online pouring so as to keep the liquid level stability of casting mold.

4. Effective means to prevent blockage and oxidation reaction during nozzle operation the product supplies two circuits of argon and one circuit of compressed air: one circuit of argon is for blowing argon to the upper nozzle, the other is for argon sealing at the joint between upper and lower nozzles, and the compressed air system puts the main components under effective protection, thereby improving the reliability of mechanical operation and extending the service life.

5. Quick and reliable accident response and safe and clean handling for casting ending when the tundish is in normal pouring, the blind plate equipped at the immerged nozzle can cut off the molten steel instantly in case of pouring accident, providing the basic condition for emergency response; the blind plate is used to cut the residual flow of molten steel at the end of pouring, facilitating a safe and civilized production.

6. Full series of sizes the products are available in small, medium and large sizes for tundish quick changes at various steel throughputs for medium and small slabs and plates.

Maanshan Shuangyi Machinery Manufacturing Co., Ltd. Was established in October 1999 and has a registered capital of 21million yuan. It first passed the certification of ISO 9001 quality management system in 2002 and the affirmation of Anhui high-tech technology enterprise in 2005. The Company now owns more than 20 patented products and high-tech products and is a technology-guided private enterprise integrating design, manufacture and sales of metallurgical electromechanical equipment.

For years, the Company has been centering on science & technology-based development and has continuously increased the input in innovation, kept a close cooperation with domestic universities and major national scientific research institutes, constantly made product updating and expansion based on its original products such as tundish nozzle quick-change facilities for continuous casting, cable reels, rotary cars for coke dry quenching and RE running-water coolers, expanded the product system, developed technically advanced full-process automatic ladle capping system, automatic casting mold flux feeder, slag stopping device for converter, wire feeder and installing device for ladle bottom argon blowing, and gradually formed and perfected its four series of products, namely, molten steel flow control, metallurgy ancillary equipment, cable reels and vehicle wheels for rail transit.

In the molten steel flow control field, its tundish nozzle quick-exchange devices characterized by reliable performance, advanced technology and exchangeability with foreign products are the only domestic product that can replace imported ones. Of the metallurgy ancillary equipment, its coke dry quenching car and full-process ladle capping device of the company characterized by stable and reliable performances and domestic pioneering technology can fully replace imported products. In the urban rail traffic technological field, the company majors in the application technology of vehicle wheels for urban rail transit and the third-party logistic service of processing, delivery, intermediate repair, warehousing and transition as required by customers.

During its rapid development, the Company has also participated in the establishment of Maanshan Yijiang Refractory Ceramics Manufacturing Co., Ltd., whose leading products are high grade refractory materials for steelmaking_ long nozzles, upper and lower nozzles and stopper rods, which are used with the product of Shuangyi Machinery to form a complete molten steel flow control system for continuous casting.

The Company will continue its efforts, grasp the good development opportunity brought about by the national policy of reviving equipment manufacturing industry, provide better products to customers by its first-rate management, excellent technical and perfect service, and strive to build itself into a modern equipment manufacturing enterprise in the along-Yangtze River region in Anhui.