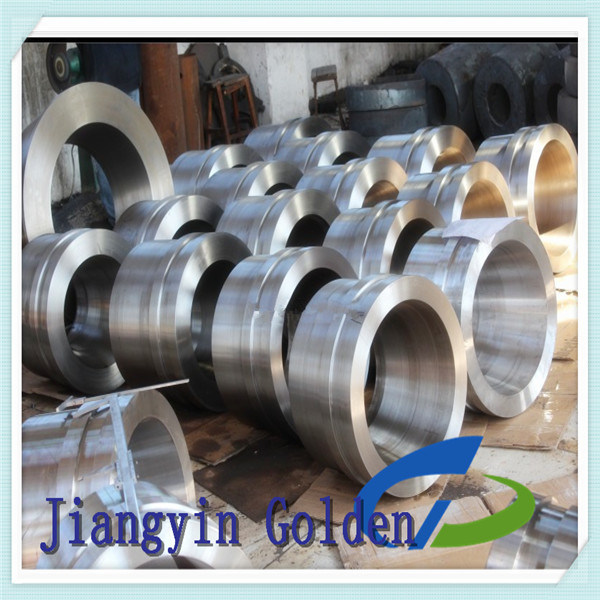

Die forging steel pipe

Specifications

OEM precision forging pipe

P265 GH, 42CrMo4, 45c, 4340, 4140, sJ355, forged pipe,

Rough machining or finishing machining forging pipe

FORGING THE FUTURE, WE DO THE BEST

OUR COMMITMENT: COMPETITIVE PRICE, HIGH QUALITY AND GOOD SEVICE

General PIPE:

Specification:

1: Die forged tube

2: Materials: Carbon, stainless and alloy steel

3: Measurement: Within 12meters

High quality flexible material forging steel PIPE:

Specification:

1: Forging steel tube

2: Materials: Carbon, stainless and alloy steel

3: Measurement: Per customer's drawing

Detail description:

1: Name: General forging steel tube

2: Certificates: ISO9001-2008, SGS, PED

3: Products ability: 3000 ton/month

4: Surface: Polishing or per customer's requirement

5: Proces: Hot forging

Quality Control:

1: On line inspection, we perform 100% on line inspection during production not to release any problem during production.

2: 100% inspection on each finished products.

3: Customer's own inspection.

4: Third party inspection.

5: UT( Ultrasonic Testing), MT, X-ray test, Spectrometer, Tensile strength, Impact test machine, Hardness tester

Packing method:

WOODEN PACKAGE

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

Forging weight is from 50 kg to 20 ton. Many kinds of materials, free size.

Smelting Process: EF+LF + VD+VC The process as follow: Ingot → Heat → Forging → Heat treatment (Normalizing+ tempering) → Inspection → Rough machining→ UT → 2th Heat treatment → Finishing machining → Inspection

Applications: The heavy forging: Forged ring, shaft, roller, flange, or gear is widely used for various industries For example: Metallurgy, mining, power station and so on.

Specifications:

Description

The heavy forging: Forged ring, shaft, roller, flange, or gear

Material

Alloy steel or stainless steel

Material standard

ASTM or GB/T3077-1999

Specification

As per specified requirements

Weight

Max. 250 ton

Smelting Process:

EF+LF + VD+VC

Process

Ingot→ Heat → Forging → Heat treatment (Normalizing+ tempering) → Inspection

→ Rough machining→ UT → 2ND Heat treatment → Finishing machining → Inspection

UT standard

EN10228, ASTM A388 or JB/T 5000.15-1998

Competitive Advantage:

The heavy forging is manufactured by large scale stated enterprise. Advanced technical process from smelting steel to forging and heat treat guarantees the product quality. Closed relationship with several famous stated enterprises guarantee "in-time delivery" and competitive price.

Excellent product quality and service, competitive price, "in-time" delivery