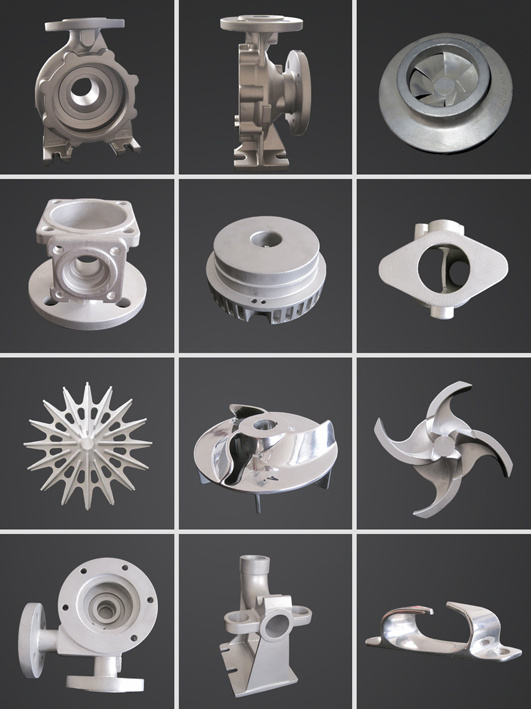

Stainless Steel Investment Casting Impeller

| Price: |

US $ 8/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

10/Piece |

| Pay Type: |

L/C,T/T,D/P |

Reference photo: Stainless steel investment casting

Material: SS 316

Process: Investment casting (silicon-glue)

Weight: 3 Kg

We can supply products with following features:

Material: Alloy steels, Carbon steel, Stainless steels, Grey iron, Ductile iron, Non-ferrous alloys, etc.

Processes: Investment casting/Lost wax casting (silicon glue, water glass, multilayer), Lost foam casting, Sand casting (resin sand casting, green sand casting), Shell-molding casting, Automatic molding line, etc.

High pressure die casting, Low pressure die casting, Gravity die casting, Centrifugal casting, etc.

Open die forging and close die forging, etc.

Plastic injection, Stamping, Assembling, etc.

Weights: 0.1 Kg , 000 Kg

Standard: ANSI, ASTM, DIN, JIS. BS

Inspection: 100 % self-inspection. 3rd party inspection available.

Certificate: EN 3.1 B certificate; ISO certificate, etc.WHY BUY FROM US

- We have our own factory and 15 cooperative factories, so supply the best quality mechanical products with the most competitive prices.

- All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. We also could provide RT, UT, MPI, WPS&PQR, etc. as per request.

- We will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request

- Our products manufactured according to standard schedule strictly, with stable quality and timely delivery.

- Hope our manufacture and service could benefit you some day in near future!

- If you are looking for this kind of products right now , please do not hesitate to contact us by any of below methods:

Riancy Wang (sales manager)

Website:www.sydensen.com

Phone: +86 159 9818 5665

| Prod Model: |

SYDN-IC-006 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Product Name: |

Stainless Steel Investment Casting |

| Material Applications: |

Carbon Steel, Alloy Steel, Stainless Steel |

| Manufacture Process: |

Investment Casting |

| Size: |

as Per Drawing |

| Weight: |

0.1-200kg |

| Surface Finish: |

Shot Blasting, Sand Blasting, Polishing |

| Casting Tolerance: |

ISO8620 CT7-9 |

| Quality Control: |

Nde, Interprocess and Final Inspection |

| Surface Preparation: |

Polishing |

| Material: |

Stainless Steel |

| Casting Method: |

Thermal Gravity Casting |

Shenyang New Densen Casting and Forging Co., Ltd., the export sales company of Shenyang Densen Group of Companies (which including 8 own foundry, forging factory and machining factories) and its more than 15 sub-contractors.

The product single weight could be from 0.01KGS to 240, 000 KGS; Manufacture processes could be casting, forging, stamping, machining, fabrication; Material could be various steel, iron and non-ferrous metals; Industries cover oil & gas, mining, food machinery, agriculture, transportation, aerospace, military and universal industries.

All factories are ISO 9001 certified. Some of them were awarded by IS O/TS16949, PED, and other professional certificates. New Densen also could provide RT, UT, MPI, WPS & PQR, and other inspection service as per request. 3rd party designated is accepted.

With the help of our distinguished customers, reliable factories, and responsible staffs, Densen has been supplying products successfully to America, Australia, Belgium, Canada, England, France, Finland, Germany, Italy, Japan, Poland, Sweden and Spain.

Densen will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special designed products available upon request.

To be one-stop sourcing base, to be customer' S reliable quality and cost control center for our customers is Densen' S principle all the time.

Just inform us what you want, we will help you to finish the other work.