Salient Features:1. The air clutch brake system has been designed to actuate with low current and as "inching", "single stroke" and "continuous running". Except "inching", the machine will always stop at the backward position of the main slider while operating in largest space.2. Two sorts of transfers system for customer to choose: swing type (general equipped) and universal type (optional), equipped with pneumatic gripper, it can simplify the demand of operation, and is more stable when the machine runs at high speed.

3. Main motor is equipped with speed-adjust transducer, PLC control system, computer automatic man-machine interface system(Optional), these equipment make lots of convenience for customer to adjust the dimension of the non-standard products.

4. Feeding wheel and claw system are both drived by cylinder, the claw can stretch automatically when it goes back in order to reduce abrasion and noise. Feeding material and stop feeding material are controlled by two claws, the feeding material system is equipped with device for avoiding material draw back.

5. Perfect inspection system: short material inspecting and eliminating, inspection of the low location of oil pressure and air pressure, transfer system floating inspection system, overload, and lightload stop system to protect the lathe and dies and prolong the service life of them.

6. When the customer prepare to adjust the side cutting screw, they only need to adjust side cam's station position, then they can achieve side cutting purpose. When the workpieces need not side cutting, customer can reset it to achieve the change from side cutting to former station.

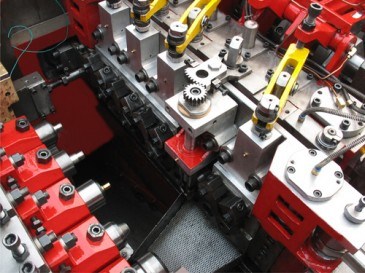

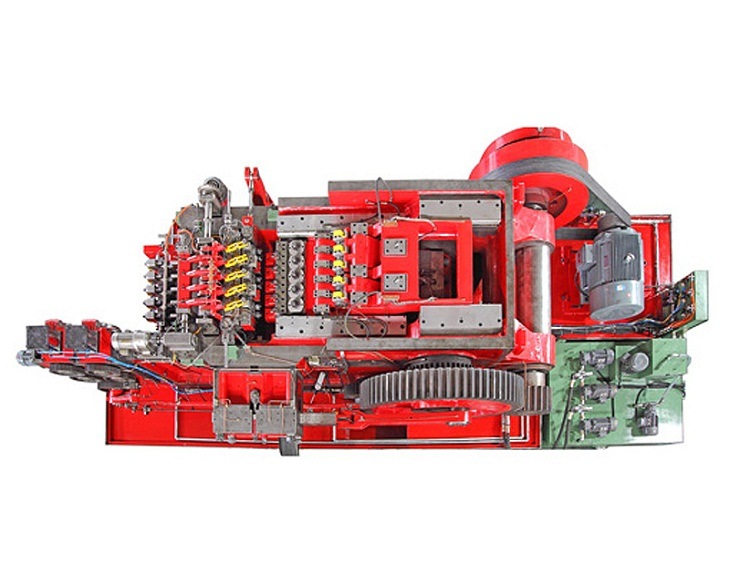

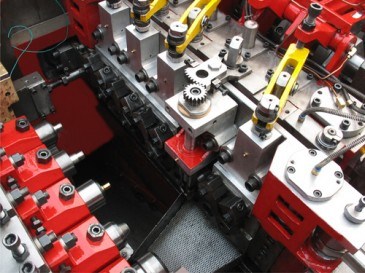

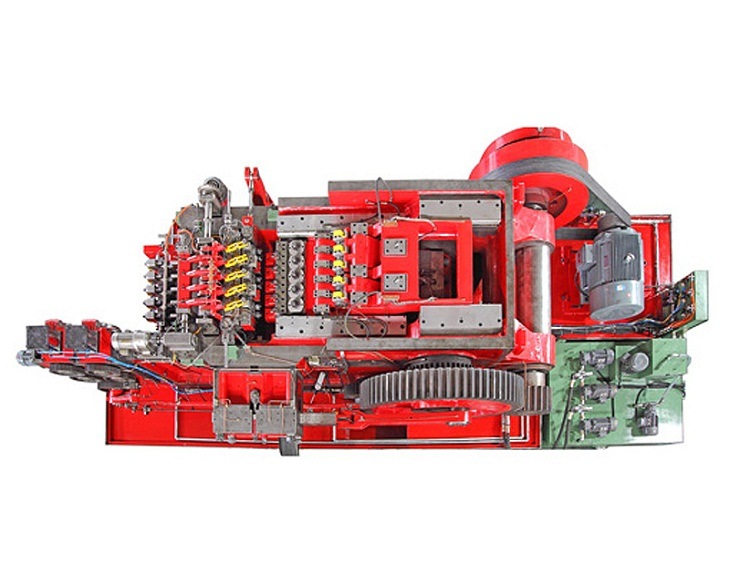

7. High strengthened-material lathe bed, lengthened main and subsidiary slider structure and "pedrailtype" slider which is adopted domestically for the first time realize "zero space" assembling which assures the precision of the main slider movement and lengthens their service life of dies.

8. The main parts of all type machines have adopted strict casting procedure and annealing disposal to assure its steel hardness and precision.

9. Circle cutting die station assures the sheared material shouter than billet diameter which also can achieve accurate right angle cutting.

10. Auto sizing material stopper can adjust the precision of material size in the state of machine running.

11. P.K.O synchronized knock out system makes the choice of molding technics flexible.

12. Transfer finger moving and cutting cams are calculated via professional computer software to make machine stable in state of high speed forging.

Three Station Screw Machine:| SPECIFICATION MODEL | SRH-63S | SRH-83S | SRH-83L | SRH-103S | SRH-103L | SRH-133S |

| FORGING STATION | 3 |

| PRODUCT | SIZE | 1/4( M6 ) | 5/16( M8 ) | 5/16( M8 ) | 3/8( M10 ) | 3/8 ( M10 ) | 1/2 ( M12 ) |

| MAX.L(mm) | 50 | 65 | 90 | 75 | 120 | 125 |

| MIN.L(mm) | HEX | 10 | 14 | 14 | 12 | 14 | 20 |

| SOCKET | 10 | 14 | 14 | 12 | 14 | 20 |

| CUT OFF DIA.MAX(mm) | 8 | 10 | 10 | 12 | 12 | 15 |

| CUT OFF LENGTH.MAX(mm) | 70 | 100 | 125 | 115 | 140 | 165 |

| KICK OUT LENGTH.MAX(mm) | 60 | 80 | 95 | 90 | 130 | 145 |

| P.K.O LENGTH.MAX(mm) | 16 | 16 | 18 | 20 | 25 | 25 |

| CUT OFF QUILL( DXL )(mm) | 26×28 | 35×56 | 35×56 | 40×60 | 45×59 | 46×80 |

| MAIN DIE HOLE( DXL )(mm) | 50×65 | 60×85 | 60×120 | 80×105 | 75×135 | 95×165 |

| DIES PITCH(mm) | 60 | 87 | 87 | 93 | 92 | 114 |

| PUNCH HOLE( DXL )(mm) | 40×77 | 45×49 | 45×115 | 50×102 | 53×115 | 60×120 |

| RAM STROKE(mm) | 120 | 140 | 160 | 160 | 190 | 240 |

| FORGING POWER(ton) | 28 | 50 | 60 | 65 | 80 | 85 |

| MAX OUTPUT( pcs /minute) | 250 | 210 | 200 | 180 | 180 | 150 |

| MAIN MOTOR(hp) | 10 | 15 | 19 | 20 | 22 | 40 |

| APPROX.WT(ton) | 6 | 9 | 10 | 13 | 15 | 20 |

| SPECIFICATION MODEL | SRH-133SL | SRH-163S | SRH-203S | SRH-203L | SRH-253S | SRH-253L |

| FORGING STATION | 3 |

| PRODUCT | SIZE | 1/2( M12 ) | 5/16( M16 ) | 3/4( M20 ) | 3/4( M20 ) | 1( M24 ) | 1( M24 ) |

| MAX.L(mm) | 300 | 150 | 200 | 300 | 250 | 300 |

| MIN.L(mm) | HEX | 100 | 25 | 40 | 100 | 60 | 125 |

| SOCKET | 100 | 25 | 40 | 100 | 60 | 125 |

| CUT OFF DIA.MAX(mm) | 15 | 18 | 23 | 23 | 29 | 29 |

| CUT OFF LENGTH.MAX(mm) | 340 | 200 | 270 | 355 | 320 | 370 |

| KICK OUT LENGTH.MAX(mm) | 325 | 175 | 240 | 335 | 290 | 340 |

| P.K.O LENGTH.MAX(mm) | 60 | 30 | 35 | 60 | 60 | 60 |

| CUT OFF QUILL( DXL )(mm) | 46×80 | 60×100 | 75×120 | 75×120 | 90×140 | 90×140 |

| MAIN DIE HOLE( DXL )(mm) | 93×350 | 100×195 | 125×240 | 125×360 | 160×294 | 160×370 |

| DIES PITCH(mm) | 114 | 126 | 138 | 138 | 174 | 174 |

| PUNCH HOLE( DXL )(mm) | 60×250 | 75×165 | 90×197 | 90×232 | 105×232 | 105×235 |

| RAM STROKE(mm) | 460 | 280 | 360 | 500 | 440 | 500 |

| FORGING POWER(ton) | 90 | 155 | 200 | 220 | 320 | 350 |

| MAX OUTPUT( pcs /minute) | 65 | 100 | 80 | 60 | 60 | 55 |

| MAIN MOTOR(hp) | 50 | 75 | 100 | 125 | 125 | 150 |

| APPROX.WT(ton) | 30 | 43 | 52 | 90 | 100 | 110 |

Four Station Screw Machine:| SPECIFICATION MODEL | SRH-64S | SRH-64L | SRH-84S | SRH-84L | SRH-104S | SRH-104L | SRH-134L |

| FORGING STATION | 4 |

| PRODUCT | SIZE | 1/4(M6) | 1/4(M6) | 5/16(M8) | 5/16(M8) | 3/8(M10) | 3/8(M10) | 1/2(M12) |

| MAX.L(mm) | 60 | 75 | 75 | 90 | 100 | 120 | 150 |

| MIN.L(mm) | HEX | 10 | 10 | 16 | 14 | 16 | 15 | 40 |

| SOCKET | 10 | 10 | 16 | 14 | 16 | 15 | 40 |

| CUT OFF DIA.MAX(mm) | 8 | 8 | 10 | 10 | 12 | 12 | 15 |

| CUT OFF LENGTH.MAX(mm) | 80 | 95 | 110 | 125 | 140 | 140 | 185 |

| KICK OUT LENGTH.MAX(mm) | 65 | 80 | 90 | 95 | 120 | 130 | 180 |

| P.K.O LENGTH.MAX(mm) | 12 | 12 | 20 | 19 | 35 | 20 | 30 |

| CUT OFF QUILL(DXL)(mm) | 30×45 | 30×45 | 35×56 | 35×50 | 40×66 | 45×59 | 46×80 |

| MAIN DIE HOLE(DXL)(mm) | 50×85 | 50×110 | 60×105 | 60×120 | 80×135 | 75×135 | 93×190 |

| DIES PITCH(mm) | 60 | 60 | 87 | 80 | 93 | 92 | 114 |

| PUNCH HOLE(DXL)(mm) | 32×60 | 40×90 | 45×110 | 45×115 | 50×111 | 53×115 | 60×170 |

| RAM STROKE(mm) | 120 | 132 | 150 | 160 | 160 | 190 | 270 |

| FORGING POWER(ton) | 30 | 40 | 65 | 60 | 85 | 80 | 120 |

| MAX OUTPUT(pcs/minute) | 280 | 250 | 180 | 180 | 150 | 160 | 125 |

| MAIN MOTOR(hp) | 15 | 15 | 20 | 22 | 30 | 30 | 50 |

| APPROX.WT(ton) | 7.5 | 10 | 11 | 12 | 17.5 | 18 | 28 |

| SPECIFICATION MODEL | SRH-134S | SRH-164S | SRH-164L | SRH-204S | SRH-204L | SRH-254S | SRH-254L |

| FORGING STATION | 4 |

| PRODUCT | SIZE | 1/2 (M12) | 5/8(M16) | 5/8(M16) | 3/4(M20) | 3/4 (M20) | 1(M24) | 1(M24) |

| MAX.L(mm) | 125 | 150 | 200 | 200 | 250 | 150 | 250 |

| MIN.L(mm) | HEX | 20 | 25 | 50 | 40 | 60 | 40 | 60 |

| SOCKET | 20 | 25 | 50 | 40 | 60 | 50 | 60 |

| CUT OFF DIA.MAX(mm) | 15 | 18 | 18 | 23 | 23 | 29 | 29 |

| CUT OFF LENGTH.MAX(mm) | 165 | 200 | 270 | 270 | 320 | 220 | 320 |

| KICK OUT LENGTH.MAX(mm) | 145 | 175 | 230 | 240 | 285 | 185 | 290 |

| P.K.O LENGTH.MAX(mm) | 42 | 45 | 36 | 35 | 60 | 30 | 60 |

| CUT OFF QUILL(DXL)(mm) | 46×80 | 60×100 | 60×120 | 75×120 | 75×120 | 90×140 | 90×140 |

| MAIN DIE HOLE(DXL)(mm) | 95×165 | 100×195 | 100×240 | 125×240 | 125×294 | 160×210 | 160×294 |

| DIES PITCH(mm) | 114 | 126 | 126 | 138 | 138 | 174 | 174 |

| PUNCH HOLE(DXL)(mm) | 60×120 | 75×165 | 75×200 | 90×197 | 90×232 | 105×180 | 105×232 |

| RAM STROKE(mm) | 240 | 280 | 360 | 360 | 430 | 300 | 440 |

| FORGING POWER(ton) | 120 | 175 | 200 | 220 | 285 | 360 | 320 |

| MAX OUTPUT(pcs/minute) | 150 | 100 | 100 | 80 | 70 | 80 | 60 |

| MAIN MOTOR(hp) | 50 | 75 | 75 | 100 | 125 | 125 | 125 |

| APPROX.WT(ton) | 26 | 49 | 51 | 64 | 76 | 86 | 100 |

Five Station Screw Machine:| SPECIFICATION MODEL | SRH-65S | SRH-65SL | SRH-85S | SRH-105S | SRH-135S | SRH-165S | SRH-205L |

| FORGING STATION | 5 |

| PRODUCT LENGTH MAX(mm) | 35 | 50 | 60 | 110 | 90 | 95 | 205 |

| CUT OFF DIA.MAX(mm) | 12 | 8 | 16 | 17 | 22 | 26 | 30 |

| CUT OFF LENGTH.MAX(mm) | 45 | 70 | 60 | 140 | 70 | 80 | 250 |

| KICK OUT LENGTH.MAX(mm) | 45 | 60 | 70 | 120 | 100 | 110 | 220 |

| P.K.O LENGTH.MAX(mm) | 10 | 13 | 20 | 30 | 20 | 30 | 45 |

| MAX CHUCK TURN LENGTH(mm) | 20 | 30 | 40 | 40 | 50 | 60 | 100 |

| CUT OFF QUILL(DXL)(mm) | 40×60 | 28×46 | 50×80 | 50×80 | 70×75 | 85×90 | 95×120 |

| MAIN DIE HOLE(DXL)(mm) | 50×85 | 50×65 | 75×110 | 80×150 | 90×140 | 100×160 | 125×240 |

| DIES PITCH(mm) | 69 | 60 | 87 | 93 | 114 | 126 | 138 |

| PUNCH HOLE(DXL)(mm) | 40×80 | 40×80 | 50×90 | 50×120 | 65×120 | 75×155 | 90×220 |

| RAM STROKE(mm) | 100 | 120 | 140 | 200 | 175 | 200 | 360 |

| FORGING POWER(ton) | 55 | 45 | 110 | 140 | 185 | 220 | 300 |

| MAX OUTPUT(pcs/minute) | 160 | 240 | 140 | 160 | 120 | 90 | 65 |

| MAIN MOTOR(hp) | 15 | 15 | 30 | 40 | 50 | 100 | 125 |

| APPROX.WT(ton) | 11 | 9.5 | 16 | 24 | 26 | 45 | 77 |

Six Station Screw Machine:| SPECIFICATION MODEL | SRH-66S | SRH-86S | SRH-106L | SRH-136S | SRH-256S | SRH-256L | SRH-276L | SRH-306S |

| FORGING STATION | 6 |

| PRODUCT LENGTH MAX(mm) | 35 | 60 | 150 | 90 | 135 | 135 | 300 | 165 |

| CUT OFF DIA.MAX(mm) | 12 | 16 | 17 | 22 | 34 | 34 | 38 | 42 |

| CUT OFF LENGTH.MAX(mm) | 45 | 60 | 140 | 70 | 140 | 280 | 400 | 180 |

| KICK OUT LENGTH.MAX(mm) | 45 | 70 | 120 | 100 | 150 | 260 | 340 | 180 |

| P.K.O LENGTH.MAX(mm) | 10 | 20 | 30 | 20 | 40 | 50 | 60 | 55 |

| MAX CHUCK TURN LENGTH(mm) | 20 | 40 | 40 | 50 | 90 | 120 | 140 | 100 |

| CUT OFF QUILL(DXL)(mm) | 40×60 | 50×80 | 50×80 | 70×75 | 110×155 | 110×155 | 110×140 | 115×140 |

| MAIN DIE HOLE(DXL)(mm) | 50×85 | 75×110 | 80×150 | 90×140 | 155×220 | 155×280 | 178×385 | 195×250 |

| DIES PITCH(mm) | 69 | 87 | 93 | 114 | 174 | 174 | 195 | 210 |

| PUNCH HOLE(DXL)(mm) | 40×80 | 50×90 | 50×120 | 65×120 | 110×220 | 110×240 | 120×250 | 135×280 |

| RAM STROKE(mm) | 100 | 140 | 200 | 175 | 280 | 400 | 500 | 320 |

| FORGING POWER(ton) | 65 | 135 | 170 | 220 | 550 | 550 | 800 | 900 |

| MAX OUTPUT(pcs/minute) | 150 | 130 | 120 | 110 | 60 | 60 | 35 | 50 |

| MAIN MOTOR(hp) | 20 | 40 | 50 | 75 | 150 | 175 | 200 | 300 |

| APPROX.WT(ton) | 13 | 18 | 27 | 30 | 108 | 128 | 220 | 155 |

HARBIN RAINBOW TECHNOLOGY Co., Ltd. Comes from China National Machinery Import and Export Corp. Harbin branch. By many years market development and experience accumulation, now we have became the biggest Chinese fastener equipment dealer and turnkey consultants of fasteners manufacturing project for abroad customers.

We are supplying high quality and reliable machines for the entire fastener industry with our professional and timely after sale service, our main products include wire drawing machine, Bolt Maker, Nut Maker, Part Former, Heading Machine, Thread Rolling Machine and Mesh Belt Furnace.

With our business reputation and professionalism, our company has experienced a significant growth in business during the recent years and invested in following companies: Zhejiang Shengrui Machinery Co., Ltd., Zhejiang Dongrui Machinery Industry Co., Ltd., Suzhou Industrial Park Wuzhong Electric Furnace Manufacturing Co., Ltd., and Wuxi Pingsheng Science & Technology Co., Ltd., etc. We do these factories' foreign market developing and have received highly praises from a lot of customers.

We have established reputation in countries such as India, Iran, US, Europe and Southeast Asia where we have core customer bases. Meanwhile, we are well respected by the domestic factories and the customers in the mechanical and electrical business.

We have the confidence, backed by our professional knowledge and experience in the mechanical and electrical business, to develop the foreign markets for our home enterprises and to open up the Chinese markets for the companies abroad.

We abide by the principles of honesty, credibility, and mutual-benefit, and do our best to serve clients and customers both at home and abroad. With our top-notch professional knowledge and trading experience, we have seen our market development ability and actual business growth with an increasingly faster pace. We sincerely look forward to working with you to facility your company's foreign market development and China market expansion. Let's build a great future together!