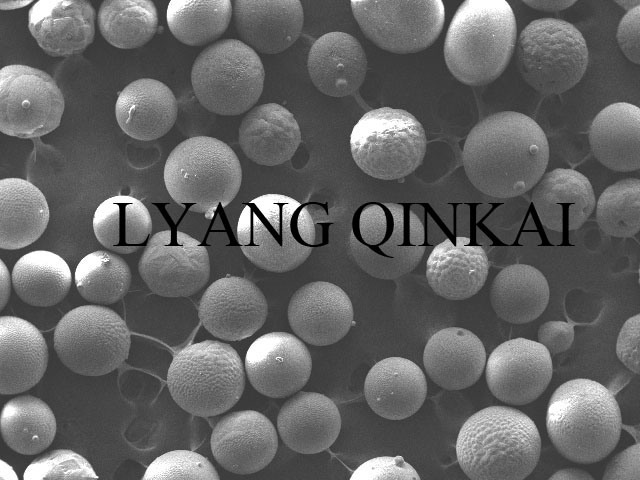

1. Round solid ball shape, saving binder addition;

2. High refractoriness and service temperature;

3. Good air permeability and excellent dispersibility;

4. Lower thermal expansion rate and thermal conductivity;

5. Lower bulk density, lower true specific gravity and lower specific surface area;

6. Standard particle sizes;

7. Easily reclaimed and lower breakage rate during dry crushing;

8. Single application, no need mix with other foundry sands;

9. To reduce pollution and protect environment.

Lyang Qinkai Trading Co., Ltd. has focused on producing and trading ceramic foundry beads, high silica fiberglass mesh filters, water based foundry coatings and alcohol based foundry coatings.

Our company's production equipment includes: 16 product lines of ceramic foundry beads with an annual production of over 25000 tons; 3 product lines of water based foundry coating and alcohol based foundry coating with an annual production of 3000 tons; And 3 product lines of high silica fiberglass mesh filter with an annual production of 20, 000sqm.