Key Specifications/Special Features:

Production flow:

Drawings→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product check→ packing →delivery strict

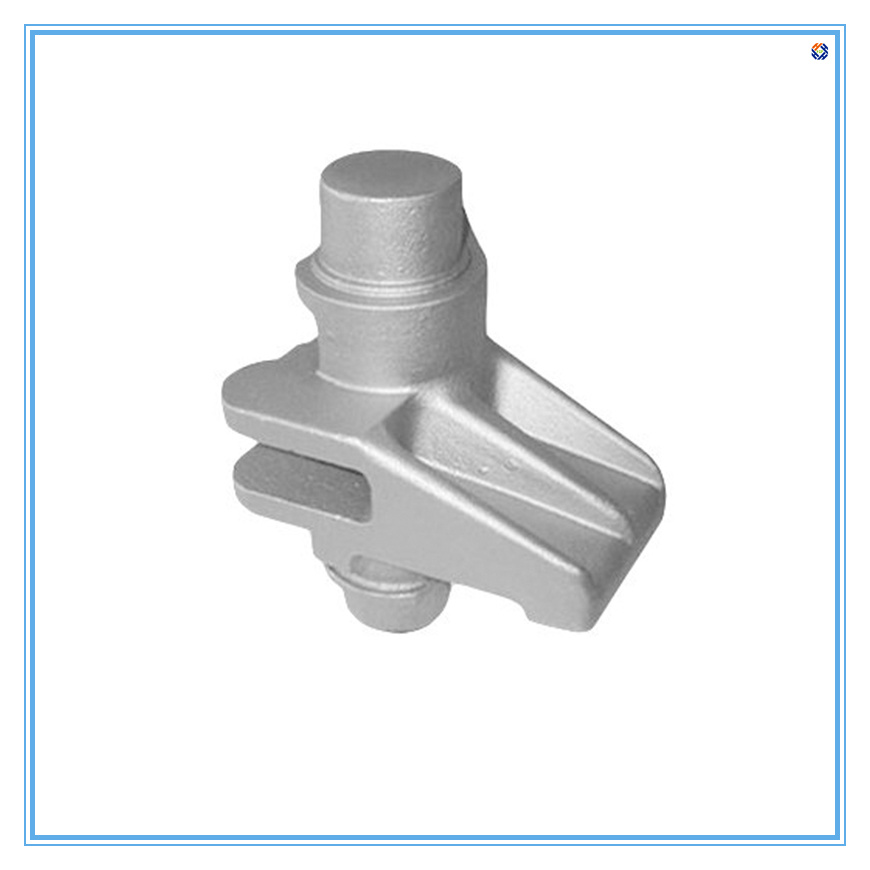

About the product

Aluminum die casting

Casting process

Sand casting, investment casting

Casting material

Aluminum, aluminium alloy

Standard

ISO 9001:2008

Machining and processing

Heat treatment, polishing, sand blasting, painting, electro-plating, chemical plating, and other machining processing

Inspection equipments

Spectrum analysis instrument, metallurgical analysis, tensile strength tester, hardness tester, roughness tester, deflection tester, impact test machine, projector, altimeter, scale micrometer, pressure tester

Quality control:

(1) Machinery properties and chemical components testing after raw casting

(2) Hardness checking after heat treatment

(3) Dimensions testing after machining

(4) Quality control checks though all the following flow:

Drawings→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product check→ packing →delivery strict

Service

(1) OEM and custom-made service

(2) Full machining, primer painting, and surface treatment

(3) Full material testing process

(4) Quality control

Inspection:

Inspection: in-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: three-coordinates measuring machine,hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

| Material | Aluminum alloy A380,A360.ADC12,Zinc alloy 3#zinc,5#zinc and 7#zinc,etc |

| Designs | 1.As per the customer's drawings

2.As per the customer's samples |

| Surface treatment | 1.Sand blasting

2.Power coating

3.Painting

4.Anodization

5.Electrophoresis

6.Zinc plating

7.Black oxidation |

| Software | Pro/E, Auto CAD, CAXA UG, CAD/CAM/CAE |

| Certificate | ISO9001:2008, ROHS,SGS |

| Service | OEM service available |

| Products | All kinds of aluminum &zinc alloy casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

| Advantage | 1.With 8 years in Aluminum & zinc alloy casting;

2.Near Q Port and Air Port;

4.Passed ISO9001:2008/Rosh/SGS

5.From Casting to Finished surface, Owned casting, polishing and plating workshops, We can offer Good quality and strict delivery time.

6.With samples and order: We can offer dimension report,Chemical composition and Mechanical properties |

| Inspection | 1.Foundry in-house

2.Third Party inspection available upon requirement |

| Packing | Pearl cotton bag inner and plastic pallet and export carton |

| Payment | T/T,L/C

|

Qingdao Haozhifeng Machinery Co., Ltd is a professionally managed hardware company with more than10 years experience in exporting business. It has five Branches which specializes in Casting parts, Auto parts, Forging parts, Stamping parts, and Machining parts. The company owns two factories besides of 100 close cooperated subcontractors. We have the capability to ship up to 80 20FT containers per month to Europe and the United States.

ISO9001, achieved in 2008, ensures that orders are carefully and expertly handled by our team of graduate engineers who understand the importance of timetable, the quality of the goods and the quality of the packing.

Our administration department is very efficient so from the time you order until the time you receive the goods we monitor the order progress and give our customers regular feedback.

You can order the complete range and get one stop service from us, as we have an advanced warehouse storage system.

Choosing Qingdao Haozhifeng as your supplier will be a good choice for you just as it is for our many exisiting international customers