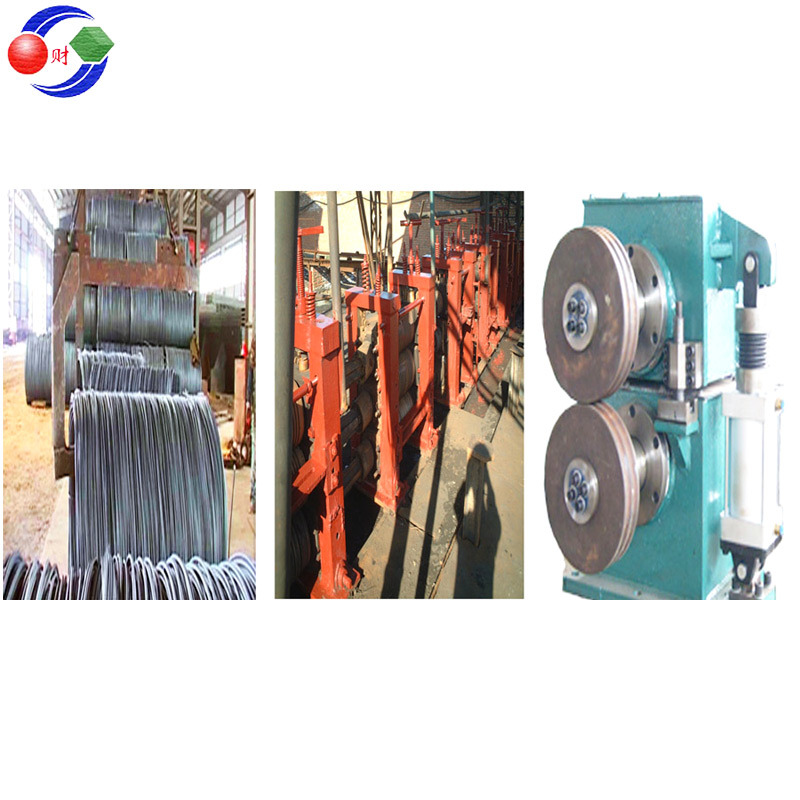

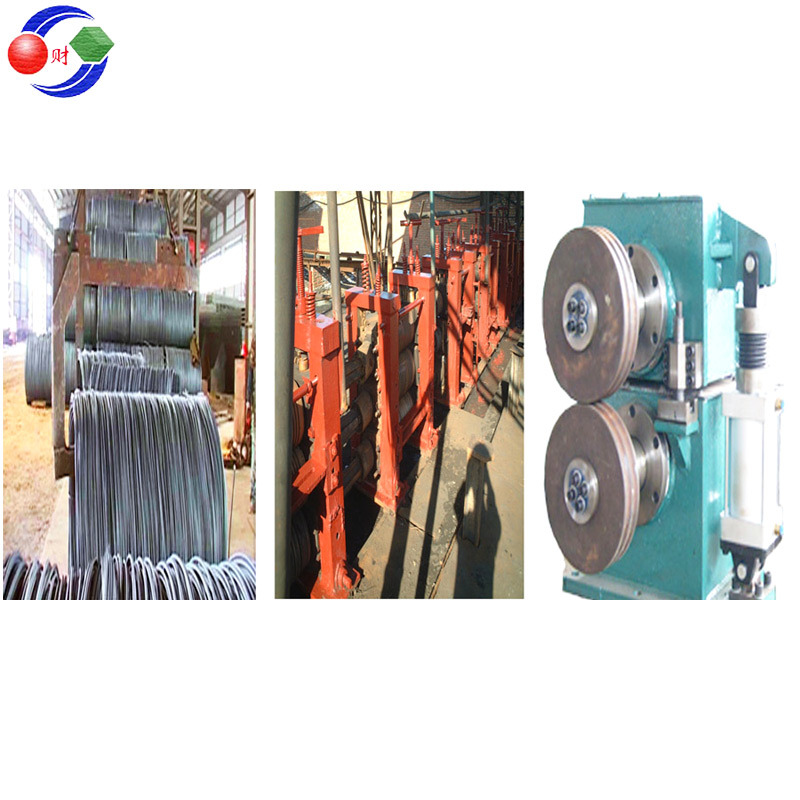

Anshan Ying Yat Trading Co., LTD, i. E. AnShan HongMing Metallurgical Machinery Co., Ltd. Is a large comprehensive group enterprise which combines scientific research, metallurgical equipments processing, steel manufacturing, commercial trading and so on. We process top-ranking scientific researchers as well as experienced team of production, management, and marketing.

We have our own right for machinery imports and exports, abundant technical force, numerous scientists and engineers, which combines design, making, installing, debugging, trial production, training and so on as a whole perfect service.

We undertake kinds of steel rolling equipment, electric arc furnace, refining furnace and all kinds of continuous casting mill.

The types of rolling mill which we can manufacture are shown as below:

Hot mill (medium-plate mill, sheet strip mill) cold rolling mill, kinds of high frequency welded pipe machine, channel steel, H-section, Angle, I-beam, deformed bar, wire rod and all kinds of high-tech mill.

The machining workshop, rivet welding workshop, casting / forging workshop and other branch factories what affiliated to our company can process kinds of work-pieces and equipments. For rolls, there are plate rolling mill roll, Section rolling mill roll, building materials rolling mill roll and various shafts.

Furthermore, we can produce reducer, coupler, universal joint, through water cooling, plate bending machine, trimming shears, lath cutter, flattening machine and so on. The material of work-piece are: Cast iron, high manganese, low alloy, high chromium-alloy, low chromium-alloy infinite chilling etc.

1. Smelting furnace

Electric arc furnace, intermediate frequency induction furnace, refining furnace.

2. Kinds of furnace for heat treatment

3. Continuous casting machine

R4M, R6M

4. Steel rolling production line

| MONI ROLLING MILL Equipment list:(billet size:1302x3000-12000mm finished products:φ screw thread10-φ32,speed:15m/s,φ screw thread 6-φ12,speed:90m/s,angle bar:,2.5-5#,flat bar :25×3-50×5, annual production:30000T) |

|

|

| NO. | Equipment list | Unit | QTY | UNIT WEIGHT | TOTAL WEIGHT | UNIT PRICE | TOTAL PRICE | Note |

|

|

| (T) | (T) | USD | USD |

|

|

| First, | Machinery and equipment around the heating furnace |

|

|

|

|

|

|

|

|

|

| 1 | Feeding bench | Group | 1 | 18 | 18 | 1283.333333 | 23100 |

|

|

|

| 2 | Into the furnace roller | Group | 3 | 8 | 24 | 1283.333333 | 30800 |

|

|

|

| 3 | Rack Pusher | set | 1 | 18 | 18 | 1750 | 31500 |

|

|

|

| 4 | Tapping machine | set | 1 | 7 | 7 | 1750 | 12250 | With sliding |

|

|

| 5 | roller before roughing rolling mill | set | 1 | 5 | 5 | 1283.333333 | 6416.666667 |

|

|

|

| Subtotal |

|

|

| 72 |

| 104066.6667 |

|

|

|

| Second, | Rolling district machine (Morgan Mill) |

|

|

|

|

|

|

|

|

|

| A | roughing rolling mill |

|

|

|

|

|

|

|

|

|

| 2 | Φ450Two roller bearings rolling mill(2V4V) | set | 5 | 27 | 135 |

|

| With sliding, Morgan closed style model, you can quickly change the roll, including a drum type universal shaft and bracket, bridge, guide and guard beams |

|

|

| B | Midle rolling mill |

|

|

|

|

|

|

|

|

|

| 1 | Φ350Two roller bearings rolling mill(9H10H11H12H) | set | 4 | 15.3 | 61.2 |

|

| the same as the above |

|

|

| C | finishing rolling mill |

|

|

|

|

|

|

|

|

|

| 1 | Φ320Two roller bearings rolling | set | 5 | 12.8 | 64 |

|

| the same as the above |

|

|

| 2 | Φ320Two roller bearings rolling(V) | set | 3 | 13.2 | 39.6 |

|

| 3 |

|

|

| 3 | Vertical looper | set | 5 | 2.2 | 11 |

|

|

|

|

|

| Subtotal rolling mill area |

|

|

| 310.8 | 1866.666667 | 580160 |

|

|

|

| Third, | Hardened reducer |

|

|

|

|

|

| Gear Material:20CrNi2MoA |

|

|

| 2 | φ450 Composite reducer | set | 5 | 20 | 100 |

|

| Hardened |

|

|

| 3 | φ350Composite reducer | set | 4 | 8.7 | 34.8 |

|

| Hardened |

|

|

| 4 | φ320Composite reducer | set | 8 | 4.7 | 37.6 |

|

| Hardened |

|

|

| 5 | Motor and gear reducer couplings | set | 17 | 0.5 | 8.5 |

|

|

|

|

|

| Subtotal Hardened reducer |

|

|

| 180.9 | 3033.333333 | 548730 |

|

|

|

| Fouth, | After cooling bed section |

|

|

|

|

|

|

|

|

|

| 1 | apron Front roller and air through roller | Group | 1 | 18 | 18 |

|

|

|

|

|

| 2 | Stepping cooling bed (11.5mX78m) | M | 78 | 5.3 | 413.4 |

|

| with roller, row steel chain, steel shift car, under the cooling bed conveyor roller |

|

|

| 3 | After cutting roller A | Group | 3 | 2.7 | 8.1 |

|

|

|

|

|

| 4 | After cutting roller B | Group | 2 | 2 | 4 |

|

|

|

|

|

| 5 | Segmented roller | set | 1 | 13.8 | 13.8 |

|

|

|

|

|

| 6 | Pinto shift steel machine | set | 1 | 7.8 | 7.8 |

|

|

|

|

|

| 7 | Finishing the transfer chain | set | 1 | 15.7 | 15.7 |

|

|

|

|

|

| 8 |

|

|

|

|

|

Our company is a big exporter of various kinds of steel and iron products, metal mineral.

One of our strongest parts is steel rolling mill and machinery/ equipment & metal processing.

Here are our steel products:

Steel plate/sheet/coil, steel pipe/tube, steel bar/rod, section steel (angle bar, flat bar, channel bar, I-beam, H-beam, wire rod/steel wire and stainless steel products.

The steel rolling mill offered by us can produce steel bar/rod, section steel (angle bar, flat bar, channel bar, I-beam, H-beam, steel rails and wire rod/steel wire.

Meantime, we are also dealing with the forging, casting, machining, heat treatment, melted-zinc-bath, other equipment (motor, reducer, etc) and furnace (heating, annealing, tempering, melting and so on).

If you have any doubts, please contact us without hesitate and send us the full inquiry with the detailed specification, material, size & quantity.