DDR3 PIN

Products Information

SATA PIN SATA HARPOON PCIE PIN SATA PIN2

Connector for PC Board

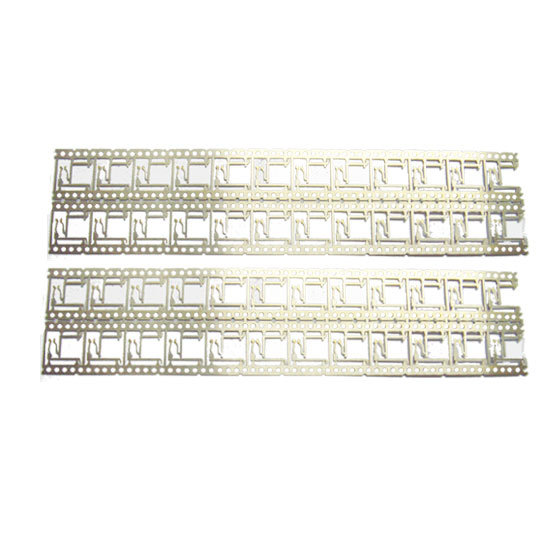

Product Name: DDR240 PIN

Spacing: 1.0MM

Material & Thickness: C2680R-EH T=0.1

CAV: 16; 16PCS at a stamping

Dimension: 23.0*8 MM

Tolerance: Standard tolerance + 0.03MM Critical dimension tolerance 0.01

Stamping speed: 700SPM

Capacity: 100, 000K

Machine: High precision Longmen vibration force

Pins: 240

About Us

Established in 1982, Helioway Group is a professional Hardware company specialized in mould design, mould manufacturing of connectors and casing for computer, cell phone, consumer electronics, auto parts etc. As well as precision metal stampings production.

We set up a plant in Guangzhou in Nov. 1999.

Helioway focuses on the R&D of high speed precise progressive die as well as stamping production since its establishment.

We have 86 die machines including BRUDERER. KYORI etc.

Process technology capability:

A: Zero loss of material use

B: The min. Space between connectors is 0.4mm

C: The pressing speed can reach 1000SPM

D: The precision of is ± 0.01mm

E: The rate of hole diameter and thickness is 0.85: 1

F: The stamping material thickness is 0.05-1.0mm

Company History

Mar, 2001

Helioway developed 2 x 16 Pin PCI connectors which helped our customer save about 40%'s cost and became a key supplier for world leading PC provider.

Jan. 2003

We developed a lot of products used on DIMM 168, PCI, PCI-E, DDRII, DDR III for PC main board with low cost, high quality which enhanced customers' competitiveness.

May, 2003

We became a approved supplier for FCI.

Jan. 2005

Helioway began to implement ISO-14001 quality control system and G/P system.

Helioway became an approved supplier for Molex, Tyco.

DEC, 2006

Helioway passed ISO-9001 & ISO-14001 quality system authentication.

Feb. 2008

Helioway began to participate all mould processing. We can do wire cutting, buffing, surface miller, surface-grinding etc. Also, we can provide one-stop service including mould design, mould making, parts manufacturing and stamping.

Mar. 2008

We developed the first HDMI insert molding with the cooperation of customer.

2009

We developed USD3.0, HDMI D TYPE

2010

We developed HDMI material saving mould and LED bracket products.

Helioway committed to the fast, correct and firm work method. We have dedicated to mould manufacturing technology and stamping production in 4C industry. By continuously deepen technology, we make great efforts to meet and exceed customer expectations.

|

Description of Products: |

Connector Terminal/DDR3 Pin |

|

Product material |

Phospor copper, bronze, etc, according to buyer' s requirment.

Plating: Tin, Silver, Nickel, Gold, according to buyer. |

|

Precision |

≤ 0.01mm |

|

Roughness |

1.6UM RA-6.3UM RA, or N7-N9 |

|

PROCESS |

Purcahsing order→ Engineering appraise and Request for change→ Layout design→ New product meeting→ Die design and Material plan→ Incoming material check→ Die processing→ Die Assembly→ Die trial→ Sample check→ Sample internal approval→ Sample submission→ Die Buyoff |

|

FINISH |

The type of surface treatment depends on the volume or according to customer' s requirement |

|

INSPECTION |

5~10 Samples with full dimension report send to customer for approval before delivery. |

|

CD record with construction/part drawing will be delivered with the dies. |

|

|

PACKAGING |

Wooden case, fumigation treatment. |

|

LEADTIME |

15~60 days (depending on different products) |

Established in 1982, Helioway Group is a professional Hardware company specialized in mould design, mould manufacturing of connectors and casing for computer, cell phone, consumer electronics, auto parts etc.As well as precision metal stampings production.

We set up a plant in Guangzhou in Nov.1999.

Helioway focuses on the R&D of high speed precise progressive die as well as stamping production since its establishment.

We have 86 die machines including BRUDERER.KYORI etc.

Process technology capability:

A:Zero loss of material use

B:The min.Space between connectors is 0.4mm

C:The pressing SPM can reach to 1000-1500

D:The precision parts tolerance can control in +/-0.01mm

E:The rate of hole diameter and thickness is 0.85:1

F:The stamping material thickness is 0.07---1.00mm

Company History

Mar, 2001

Helioway developed 2 x 16 Pin PCI connectors which helped our customer save about 40%'s cost and became a key supplier for world leading PC provider.

Jan.2003

We developed a lot of products used on DIMM 168, PCI, PCI-E, DDRII, DDR III for PC main board with low cost, high quality which enhanced customers' competitiveness.

May, 2003

We became a approved supplier for FCI.

Jan.2005

Helioway began to implement ISO-14001 quality control system and G/P system.

Helioway became an approved supplier for Molex, Tyco.

DEC, 2006

Helioway passed ISO-9001 & ISO-14001 quality system authentication.

Feb.2008

Helioway began to participate all mould processing.We can do wire cutting, buffing, surface miller, surface-grinding etc.Also, we can provide one-stop service including mould design, mould making, parts manufacturing and stamping.

Mar.2008

We developed the first HDMI insert molding with the cooperation of customer.

2009

We developed USD3.0, HDMI D TYPE

2010

We developed HDMI material saving mould and LED bracket products.

Helioway committed to the fast, correct and firm work method.We have dedicated to mould manufacturing technology and stamping production in 4C industry.By continuously deepen technology, we make great efforts to meet and exceed customer expectations.

Our clients include:

Singatron Enterprise Co.Ltd

Winning Enterprise Co., Ltd

Main Super Enterprise Co., Ltd

WIESON Enterprise Co., Ltd

Taisol Electronics Co., Ltd

Molex

Tyco

Fci

Sinbon