1. Description

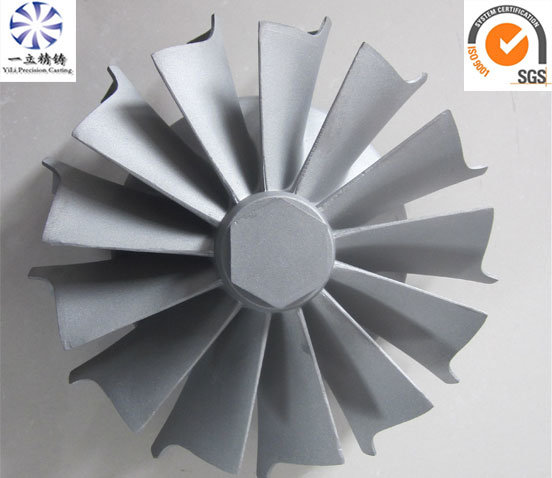

Vacuum Casting High Temperature Alloy Turbine Rotor Blades

What is our mainly business?

Products and service:

Series 1: Car and truck turbocharger parts

Turbine wheel, compressor wheel, nozzle ring, turbine

Rotor, turbine wheel shaft, diffuser, turbine housing, compressor housing, etc.

Series 2: Marine and locomotive turbocharger parts

Turbine wheel, compressor wheel, nozzle ring, diffuser, turbine blade, turbine housing, compressor housing, seal ring carrier\bearing support, etc.

Series 3: Aviation turbojet engine spare parts

Turbine wheel, compressor wheel, nozzle guide vanes, turbine blade, diffuser, intake casing, casing outer ring, inlet casing, jet nozzle, etc.

Series 4: Gas turbine, steam turbine parts

Turbine wheel, guide vane, compressor wheel, gas and steam turbine blade, etc.

Series 5: Oil, gas, chemical, pump, compressor parts

Pump impeller, close impeller, blower impeller, compressor impeller, water pump impeller, turbine blade, turbine impeller, Guide vane, etc.

A-1: Casting method:

At present, the precision casting process we adopt include: Vacuum casting, lost wax investment casting and low pressure casting, the vacuum casting products' advantage is the most outstanding in our company.

(1) Vacuum casting can help the excluding of gas in the mould and inhibit the turbulence and the volume of gas. It can overcome the disadvantages of the traditional casting, and make the filling ability of the metal liquid improve significantly.

(2) Because of the improvement of filling ability while vacuum casting, the metal liquid's casting temperature can be lower than the traditional casting about 20~30 degree.

(3) Possibility of casting parts with big difference on the wall thickness, thin-walled parts and parts with high quality and complicated shapes.

B: 5-Axis Machining

Our company introduced Japanese Sanchi MAZAK five-axis linkage CNC machining center VARIAXIS I-700. The machine is widely used in blade, impeller, mould industry and other various types of mechanical processing industry of complex curved surface parts processing, it can meet many kinds of processing needs of the medium and small box body parts and space curved surface parts.

C: Casting Machining

We have ordinary lathe, CNC Lathe and Wire-electrode cutting machine, so we can the castings machining.

Why Choose us as your cooperation partner?

A: Pass ISO9001-2008 Certification

B: Enough produce capacity and promise delivery time

C: Better quality wax, silica sol, Zircon power and Mullite Sand. All of this keep the shell we get with good quality.

D: We can provide the testing report according your need by ourself. We have domestic advanced testing laborator. Y

Another questions you will concern:

Q 1: For the casting, do you accept customized processing?

A 1: Yes, now our 100% products produce is customized processing, Now we produce the smallest casting length is 40mm, the thinnest place can meet 0.5mm, the maximum length is 500mm, the weight reached 13kg.

Q2: Now your mainly export country is?

A2: Now we have build long-term cooperation relationship with American, Iran Russia customer for blade produce.

Q3: Can I only buy few sample as testing?

A3: Yes, Of course. For you buy suitable products, at the beginning you can only buy one or two sample as testing.

Q4: Will you sign NDA for the any drawing we provide?

A4: Yes, for protect the business secret and our cooperation, it is our duty to sign NDA.

Weifang Yili Precision Casting Co., Ltd. is located in the famous industrial city, Weifang, in Shandong Peninsula, and is a professional manufacturer and high standards of precision castings.

Our main products include turbocharger spares, turbine wheels, compressor wheels, compressor impellers, gas turbine blades, nozzle rings, nozzle guide vanes, aviation power turbojets, turbofan engine turbine blades, turbine impellers of gas turbine, turbine blades of steam turbine, aviation ship engine turbine blades and other power equipment precision castings. The materials we adopt mainly include nickel base high temperature alloy, iron base high temperature alloy, cobalt base superalloy, and corrosion resistant stainless steel.