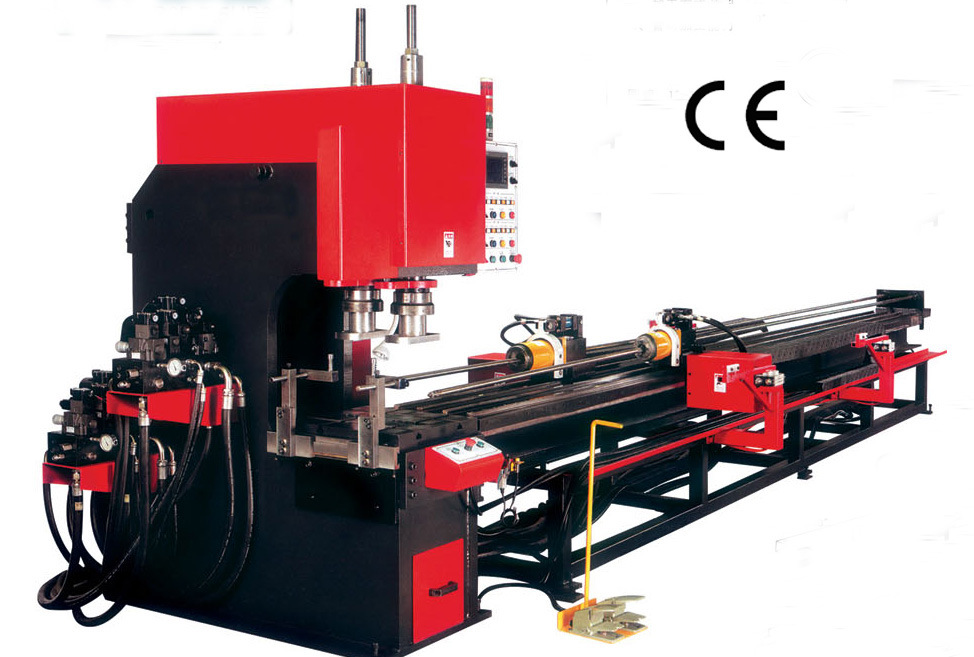

TFT human machine interface display, touch controllable display setting, digital control systems, serve motor position scaling precision and modular memory function

Operational Function: Jogging/Automatic Functions

Engineering Motion Classification: I single puncturing operation, 2 irregular interval puncturing, 3 regular interval puncturing

Oil Hydraulic System: Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

Whenever the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM. It is also featured with high speed downward moving, low speed processing and hi- speed position resume. It is available to increase the formation stability of work pieces during puncturing. In addition to increasing the activation speed, it can effectively reduce HP lead to save electrical energy.

The electrical control system is designed with human machine interface 150mm(Stroke available for positioning) the mold set is designed with 600mm in depth available for forward and backward 150mm moving accessibility Our machine is designed with the Italy-made digital scale (LCD display) with high precision.

Our machine is adopted with Japan-made serve motor driving devices and the feed-In and receiving speed can be set to high speed and high precision to enhance the productivity.

It is featured with sufficient clamping force of clamping oil cylinders and the position of work pieces is stable and uneasily loose off.

Application: Square tube rectangle pipe and round pipe puncturing

Servo Feed-in Positioning Frame Length: 7OO0mm

Body: 1500mm W: 8200mm H: 250gmm Total Weight: 5T

Yongfeng Machinery Co., Ltd is a professional machine manufacturer, mainly produce the following series of products: GQ40A, GQ40B opening reinforcing steel bar cutting machine, GQ50, 60 enclosed reinforcing steel bar cutting machine, GQ40Cenclosed reinforcing steel bar cutting machine, GW50 reinforcing steel bar bending machine, GW40A reinforcing steel bar bending machine, GW40Z reinforcing steel bar bending machine(patented product), GW40 reinforcing steel bar bending machine, GW32 (automatic) reinforcing steel bar bending machine, GW18 (patented product) full automatic angel positioned stirrup and bending machine, GW16 full automatic angel positioned stirrup and bending machine, GJ12 reinforcing steel bar straighten cutting machine, UJW200 stucco mixer. Our products series have been researched, manufactured and improved for more than 10 years, and passed ISO9001: 2000 quality system certification, stable performance, reliable quality, reasonable price, our products are sold all over China and exported Egypt, Nigeria, Russia, Kazakhstan, Middle East and so on each country and area, receives vast user`s favorable comment deeply.

Since2007, our company pooled capital with Taiwan Yongfeng Machinery Co., Ltd to establish Lanxi Yongfeng Machinery Co., Ltd, main products are CNC, NC, TNC and PLC hydralic pipe bender, hydraulic rounding machine, hydraulic digital-control flange forming machine, punching machine, curve puncher, forging machine etc.

Welcome new and old custormers join us and negotiate business.