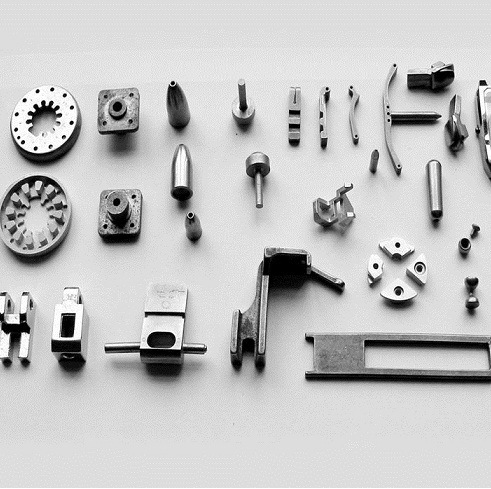

CISRI Metal Injection Molding (MIM) plant has the capabilities to achieve an annual production of 300 tons of MIM products of different alloy powders, Annual output extends to 120 million pieces. Now we can research and develop many kinds of alloys and various new products to meet the demand of precision parts for many industries. It 's honored to be the certified supplier for more than ten renowned companies around the world. With 90% of the products exported to Japan, USA and Europe.

Main product series:

W, Mo, tungsten alloy products; Tool steel products; SUS316L, SUS440C, and 17-4pH stainless steel products; Low alloy steel products; Super-alloy and heat resistant alloy products; Titanium alloy products

Metal Injection Molding (MIM) advantage:

1. Directly manufacturing small sized part (0.1-200g) with complicated geometric shapes

2. The parts tolerance can be held to +/-0.1~0.5%, glabrous surface, up to Ra3.2.

3. The parts made by Metal Injection Molding (MIM) have high relative density (95%-99%),

4. More consistent microstructure and higher mechanical property.

5. High efficency and economic solution for mass production in high volume.

6. Extensive processing for many materials

| Parameters | Investment casting | MIM |

| Minimum aperture diameter | 2mm | 0.4mm |

| Maximum depth of aperture Φ 2mm | 2mm | 20mm |

| Minimum wall thickness | 2mm | < 1mm |

| Maximum wall thickness | unlimited | 10mm |

| Φ 4mm tolerance | ± 0.2mm | ± 0.06mm |

| Surface finish(Ra) | 5μm | 1μm |

| Items | The best | Mill run |

| Angle | ± 0.5 º | ± 2 º |

| Density | ± 0.2% | ± 1% |

| Dimension | ± 0.1% | ± 0.3% |

| Roughness | Ra ∠ 1μ m | Ra∠5μm |

| Weight | ± 0.1% | ± 0.4% |

| MIM material | Density 103kg /m3 | Hardness | Tensile strength | Elongation% |

| Iron-based alloy | PIM4600 | 7.68 | 85HRB | 400 | 25 |

| PIM4650 | 7.68 | 100HRB | 600 | 15 |

| Stainless steel | 316L | 7.94 | 52HRB | 580 | 45 |

| Tungsten alloy | 95%W | 18.1 | HRC31 | 930 | 10 |

| 97%W | 18.5 | HRC33 | 890 | 6 |

| Carbide alloy | YG8X | 14.9 | HRA90 |

|

|

China Iron & Steel Research Institute Group (CISRI) is a Chinese state-owned enterprise incorporated by former Central Iron & Steel Research Institute of China and former Automation Research Institute of China.

For the last 60 years, CISRI is serving as an important R&D base and a leading provider of advanced materials and products in China. CISRI owns a broad spectrum of technical know-how and advanced products in various industrial fields such as functional materials, powder metallurgy materials, refractory metals, high temperature alloys and structural materials.

CISRI owns 8 production bases and more than twenty production lines all over China. We have China' S largest amorphous and nanocrystalline alloy production base, China' S largest flux-cored welding wire production base, China' S largest export-oriented production base of diamond blades, China' S first-class production facility for high temperature alloys and products, ect.

With 12 holding companies and 12 national centers and institutions, CISRI also serves as the innovation base for key technology in metallurgical industry, and the authoritative agency for metallurgical analysis and test.