*About company

Our company focues on the technique of Lost-wax, Silicon sol precision casting, Investment & vacuum casting, and our compay is an ISO9001: 2008 certified company engaged in manufacturing of world class Nickel base alloy castings, Stainless steel castings, Alloy steel castings, Carbon steel castings, Cast iron castings, Aluminum alloy castings. Our OEM products are widely used in the industrials of Locomotive, Aerospace, Large vessels, Construction machinery, Chemicals, Oil, Marines, Railways and Automobiles, etc.

K18 Turbo Turbine Wheel Inconel 713C Vacuum Casting

*Our advantages1Fully automatic the free cylinder pressure wax machine

2Water blasting machine for surface treatment of high standards

3Constant temperature and humidity system shell pipeline

4Efficient vacuum melting and casting furnace

5Automatic large heat treatment furnace

6Aluminum alloy low pressure casting machine

7Hot steam dewaxing autoclave

8OEM service offer

*OEM ServiceWe can produce all kinds of investment casting, vacuum casting, turbine rotor, turbocharger, turbojet engine parts, stainless steel castings, Carbon steel castings, Alloy steel castings, Aluminum alloy castings, etc. Maybe your demands of products is different from other clients, please don't worry, we can produce the product according to your drawings or samples. So the product fully meet your requirements. If you have any requirements, welcome to contact me. If you have no purchasing plan now, Welcome to record our company's information, maybe you will use them in the future. Thank you!

*Nickel-based alloy turbine used for engine Turbocharger Turbine Wheel Used for Engine

Nickel-based alloy castings is used for turbocharger or marine engine, aircraft engine, ship engine or train engine, etc.

At present, the precision casting process we adopt include: vacuum casting, lost wax investment casting and low pressure casting, the vacuum casting products' advantage is the most outstanding in our company.

(1) Vacuum casting can help the excluding of gas in the mould and inhibit the turbulence and the volume of gas. It can overcome the disadvantages of the traditional casting, and make the filling ability of the metal liquid improve significantly.

(2) Because of the improvement of filling ability while vacuum casting, the metal liquid's casting temperature can be lower than the traditional casting about 20~30 degree.

(3) Possibility of casting parts with big difference on the wall thickness, thin-walled parts and parts with high quality and complicated shapes.

*Stainless steel castings

*Stainless steel castingsStainless steel have good rustproof and corrosion resistance property.

Production flow: Drawings-Mould making-Making wax model-System shell-Roasting casting-Cut gate-Sandblasting-

Heat treatment -Sandblasting-Grinding-Sandblasting-Appearance inspection-Professional inspection-Return to repair- Fluoroscopy -Sandblasting-Incoming inspection

*Carbon steel and Alloy steel castingsThe company specializes in manufacturing of Carbon steel castings which are made up with high quality raw material so that make them durable and long lasting.

Our world class Alloy steel castings are made up with sturdy and durable raw material that make them long lasting and ensure excellent performance during usage.

*Aluminum alloy castingsProduction flow: Drawings-Mould making-Make plaster mold-Drying plaster type-Pouring-Heat treatment-Car gate-Sandblasting-Grinding-Sandblasting-Appearance inspection-Professional inspection-Grinding-Fluoroscopy-Sandblasting-Incoming inspection

*Cast iron castingsProcess: Prepare the precoated sand; Make the shell with shell mould machine; Assemble the mould; Smelting with electric furnace and pour; Inspect the chemical composition with quick analyser before pouring; Inspect the graphite structure and economy organization with metalloscope; Clean with cylinder shot blast machine; Heat treatment with electric furnace; Machine with CNC machine and drill with drill press; Brush the antirust oil on part surface.

| Weifang YiLi Precision Casting Co.,Ltd. |

| Casting Process | Precision casting, Silicasol casting, Investment & vacuum casting, Lost wax casting, Sand casting, Low pressure die casting |

| Casting Material | Nickel-based alloy, Stainless steel, Aluminum alloy, Carbon & alloy casting, Cast iron, Grey iron, Ductile iron, Iron-based superalloy,etc. |

| Standard | AISI, DIN, ASTM, JIS, BS(As per customer need) |

| Maching & processing | Heat-treatment, Polishing, sand blasting, painting, Electro-plating, Chemical plating, and other machining processing |

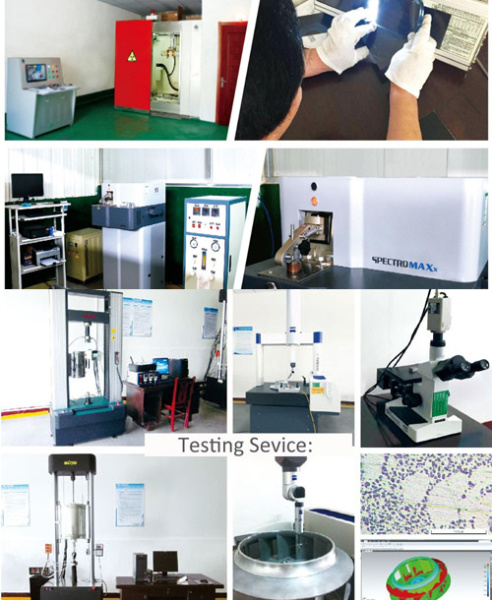

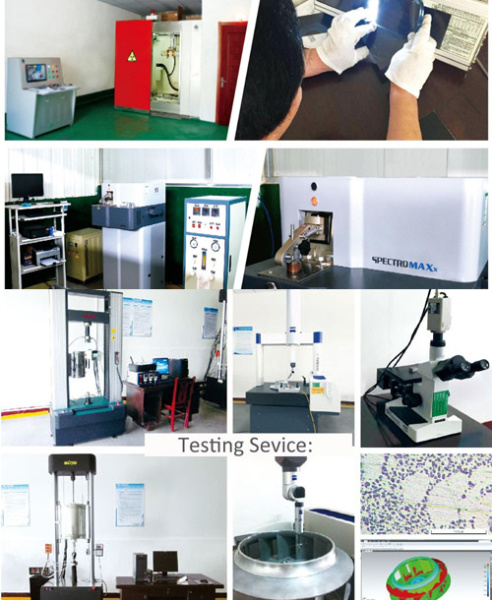

| Inspection Equipments | Spectrum analysis instrument, Metallurgical analysis,Tensile strength tester, Hardness tester, Roughness tester, deflection tester, Impact test machine, projector, Altimeter, Scal Micrometer, pressure tester |

K18 Turbo Turbine Wheel Inconel 713C Vacuum Casting

Weifang Yili Precision Casting Co., Ltd. is located in the famous industrial city, Weifang, in Shandong Peninsula, and is a professional manufacturer and high standards of precision castings.

Our main products include turbocharger spares, turbine wheels, compressor wheels, compressor impellers, gas turbine blades, nozzle rings, nozzle guide vanes, aviation power turbojets, turbofan engine turbine blades, turbine impellers of gas turbine, turbine blades of steam turbine, aviation ship engine turbine blades and other power equipment precision castings. The materials we adopt mainly include nickel base high temperature alloy, iron base high temperature alloy, cobalt base superalloy, and corrosion resistant stainless steel.

Our company has advanced production equipment, strong technical force, perfect management and high-quality assurance system. Besides, we are trained with regularity, experienced workforce, and excellent and full-range pre-sales, sales, and after-sales services. We currently have the most advanced precision casting production equipment domestically and internationally. We have introduced fully automatic cylinder pressure wax machines, water sandblasting machines, shell pipelines, high vacuum melting casting furnaces, large automatic heat treatment furnaces, aluminum alloy low-pressure casting machines, high degree automatic equipment, and fluorescent flaw detectors which are special detection equipment effectively ensuring the quality of products.

Our company not only sells products throughout China, but also exports them to the United States, Europe, the Middle East and other countries and regions. We have developed our turbine wheels with ninety models. We also manufacture other superalloy or stainless steel precision castings according to customers' demand for specific products.

Our company focues on the technique of Lost-wax, Silicon sol precision casting, Investment & vacuum casting, and our compay is an ISO9001: 2008 certified company engaged in manufacturing of world class Nickel base alloy castings, Stainless steel castings, Alloy steel castings, Carbon steel castings, Cast iron castings, Aluminum alloy castings. Our OEM products are widely used in the industrials of Locomotive, Aerospace, Large vessels, Construction machinery, Chemicals, Oil, Marines, Railways and Automobiles, etc.

Our company focues on the technique of Lost-wax, Silicon sol precision casting, Investment & vacuum casting, and our compay is an ISO9001: 2008 certified company engaged in manufacturing of world class Nickel base alloy castings, Stainless steel castings, Alloy steel castings, Carbon steel castings, Cast iron castings, Aluminum alloy castings. Our OEM products are widely used in the industrials of Locomotive, Aerospace, Large vessels, Construction machinery, Chemicals, Oil, Marines, Railways and Automobiles, etc. *Stainless steel castings

*Stainless steel castings