1. pump parts

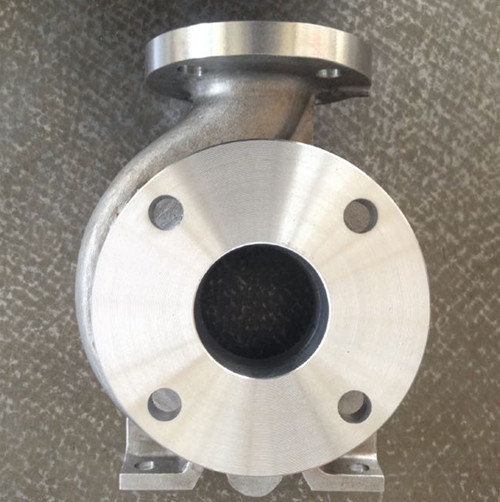

The pump parts are our main products :

| Name | pump parts |

| Parts | Casing |

| Material | Carbon steel ,stainless steel 316 ,CD4 , low alloy, high chrom, cast iron, bronze, ductile iron and so on |

| Size | According to the drawings |

| Manufacturing | Sand casting |

| Machining | CNC Lathe, Universal Lathe, CNC Cutting Machine, Dynamic Balancing Machine |

| Testing | Spectrameter, Hardness Tester, Toughness Tester, Dynamic Balancing Tester, PT Tester, Hydro Test, High Pressure 1500 psi etc. |

2.Castings manufacture craft

| Caft | Clarify | Process | Material |

| Lost Wax Casting | waterglass bonded sand | moulding | Stainless steel, carbon steel, low alloy, high chrom, cas iron, bronze, ductile iron brass, etc. |

| silicon colloidal | pouring |

| composite shell | machining |

| testing |

| Sand Casting | resin sand | moulding | Stainless steel, carbon steel, low alloy, high chrom, cas iron, bronze, ductile iron brass, etc. |

| pouring |

| silicate bonded sand | machining |

| testing |

| Lost Foam Casting |

| moulding | Stainless steel, carbon steel, low alloy, high chrom, casiron, bronze, ductile iron brass, etc. |

| pouring |

| machining |

3.Other pump parts/Castings ,please kindly send us the drawigns which is great help for our quotation and producing .

Pump Part Description | Material | Application |

| Impeller, liner, throat bush etc. | High chrome, Ceramic | For mines and other wear resistance working conditions |

| Impeller, liner, throat bush, F.P.L. Insert, etc. | Natural rubber, elastomer and polyurethane | Corrosion (especially acid) and abrasion conditions |

| Cover plate, frame plate, base, bearing housing, etc. | Grey iron and ductile iron | All kinds of working conditions |

| Expeller, expeller ring, stuffing box, etc. | Stainless steel, high chrome | Chemical industry, corrosion (especially for acid) conditions |

| Shaft, shaft sleeve, lantern ring, neck ring, etc. | Stainless steel, 1045 steel |

|

| Seal, O ring | Elastomer |

|

| Bolt | Stainless steel, 1045 steel |

|

4. Packaging of pump casing

Small part, single packed then put into paper carton then to crate.

Minimum poly wooden board thickness: 20mm

Steel band: 19×0.5mm or 15×0.5mm

Common crate size is less than 1200X1000X1000mm

Our foundry is specilized in producing the pump components such as casing, impeller, bowls, shaft and other pump spare parts meanwhile we provide customers' designed pumping solutions for any pumping requirment.

We also specialize in manufacturing the highest quality castings, all kinds of machinery parts with many material such as stainless steel, carbon steel, alloy steel, iron etc by sand casting, investment casting and lost foam process according to customers' drawings or samples.

We can make the parts final machining by our own machining shop with many advanced equipments like CNC lathe, CNC cutting machinery, miller and others controlled by experienced workers. We execuit the strict inspection by many kinds of accurate inspection tools.

We have our own trading company--Zlt International Trade Co., Ltd with the principle of high quality, perfect service and sincere integrity, on this condition, we have got very good fame from our customers who come from Germany, USA, Canada, Sweden, Israel, Hungary, Mexico, Guyana, etc

Welcome to visit our foundry in Zibo city, Shandong Province, China!