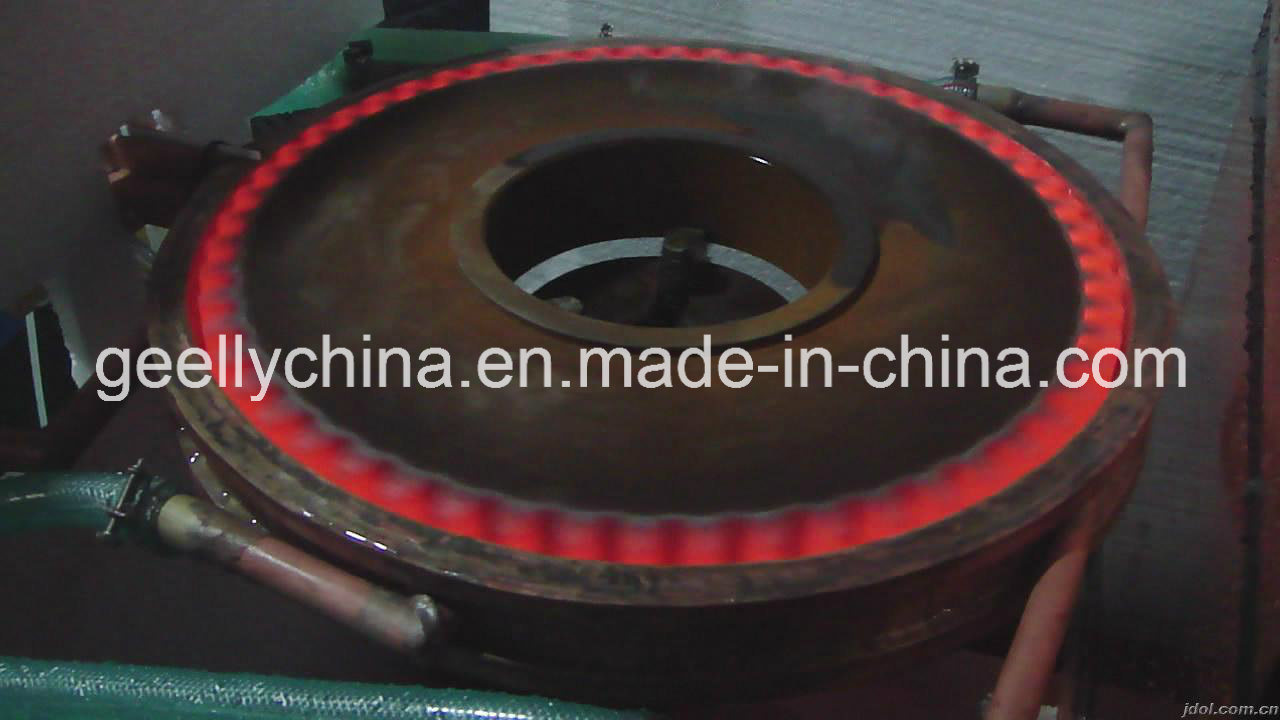

Factory Directly Sell Induction Gear Heating, Quenching, Forging Machine 120kw or 160kwApplication gear heating forging machine

1. Forging, rolling class

A. The variety of hot-rolled twist drill.

B.standard parts, hot forging fasteners, such as high strength bolts, nuts and so on.

C.drill steel, tempering brazing, forging, extrusion heating.

2. Heat treatment Class

A. The various hardware tools, hand tools, heat treatment. Such as pliers, wrenches, screwdrivers, hammers, axes and so on.

B kinds of auto parts, motorcycle accessories high-frequency quenching. Such as: crankshaft, connecting rod, piston pin, crank pin, wheel, camshaft, valves, all kinds of rocker arm, rocker shaft; transmission of various gears, spline shafts, drive axle, a variety of small axes, a variety of fork and other high-frequency quenching.

C. power tools on the gears, shafts and other high-frequency quenching.

D. a variety of hydraulic components, pneumatic components of high frequency hardening heat treatment. Such as the piston plunger, rotor pump rotor on a variety of valves for the shaft, the gear pump gear, etc. quenching.

E. Heat treatment of metal parts. Such as the various gears, sprockets, all kinds of shafts, spline shafts, pins and other high-frequency quenching.

F. Machine tool industry guide, tools swallowtail quenching treatment. ![]()

![]()

![]() Technical paramters of 160kw HI frequency induction gear heating forging machine

Technical paramters of 160kw HI frequency induction gear heating forging machine | Model | GSF-160 |

| Work power | 3 phase 380V+/-10%, 50-60HZ |

| Input voltage | 320V-420V |

| Input current | 6-300A |

| Input power | 3-160KW(power adjusted stepless) |

| Oscillation frequency | 10-50 KHZ |

| Cooling water pressure | 0.3 MPA |

Size of geneartor:

Transformer | 850*600*1330mm

780*540*520mm |

| Weight of generator ; transformer | 147kgs; 108kgs |

| Water cooling protection point | Below 45 degree celsius |

Packing detail:1.Standard wooden case, plywood case, and custormized case;

2. Inner packing: packing plastic film and foam to avoid any damage during shipping

3.Accessories: induction coilX 2, foot pedal X1, installing and operating instruction X1 and custormized;Our service 1. Pre-sale service:

- 1. recommend the most suitable machine for customers, according to their application details.

- 2. Inquiry and consulting support.

- 3. Sample testing support.

- 4. View our Factory.

2. In-sale service:

- 1. Strictly control all the prduction process

- 2. Take run test, according to relevant equipment test run regulations.

- 3. Strictly inspection the machine, before delivery

- 4. Delivery on time.

3. After-sale service:

- 1. 12 months warranty period

- 2. Within one year free warranty, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, we will provide replacement parts after detecting the faults.

- 3. If any big quality problems occurs during the guarantee period, we will send maintenance

- 4. technician to provide visiting service after checking with the customer and charge for a favorable price.

- 5. We provide a lifetime favorable price to the buyer with the materials and spare parts used in system operation, equipment maintenance.

- 6. The above mentioned are only basic after-sale service requirements, we will make more promises related to quality assurance and operation guarantee mechanism.

FAQ

China Supplies Induction Heating Power Supply

Questions and Answers:

1. Which countries your products are exported to?

Our products are sold many countries and Areas

2.How about the warranty?

All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.

3.How to install your machine?

We have paper installation instructions and videos, we will teach till you learn it.

4. Which export port you use?

Any China port is ok, usually, we will use Shenzhen ,Guangzhou ,Hongkong port, it can appoint as you like.

5.How about the payment terms and delivery time ?

Payment terms for small machines: 100% T/T, Western Union,Cash in advance.

The big machines and big amount: 30% deposit,70% before shipment (we will take relative pictures for total process for customer's confirmation)and the related papers. You can pay by T/T,L/C, Western Union or other ways.

6.If I have paid but can not receive the goods, how should I do?

Made-in-china website is a famous trade platform and has been mature those years ,every supplier on it has paid large integrity fund,and we have Chinese business licenses which can be checked on China official website or we can show it to you,so that situation will never happen,

7.What is your nature of your company:dealer or factory ?

We are manufacturer,warmly welcome to visit our factory and contact us.

![]()

Shenzhen Geelly Technology Co., Limited is specialized in manufacturing High and Medium Frequency Induction Heating heaters and related equipment.

We own gifted engineers for developing and improving of induction heating generators. We have research lab and production base, We manufacture wide range of product lines which include induction heaters in range of power from 3KW to 240KW and output frequency range from 2kHz to 1.1MHz. We also manufacture and design Gold melting furnace, Platinum melting furnace, and the coils of induction heaters. Industrial refrigerating machines. We also offer spare parts of induction heater and some auxiliary parts, such as Silver-Gold Filler Metals, foot switches, High temperature resistant insulating tape and so on.

Our induction heater have been used by more and more customers home and abroad due to the good quality and reasonable cost. Our products offer a perfect solution in the fields of metal heating soldering and brazing, forging, shaping, heat treatment and melting.

We offer technical consultation to inquires with instant feedback and recommend suitable machine models for varied applications.