Hydraulic ironwoker

Web:www.rsm-ironworker.com

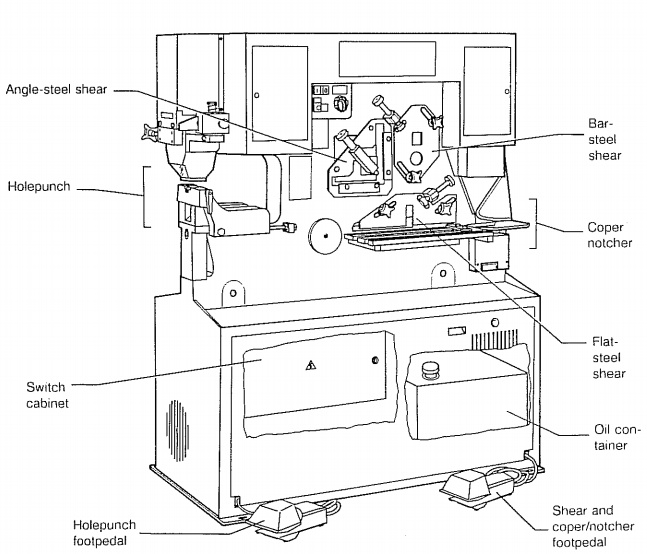

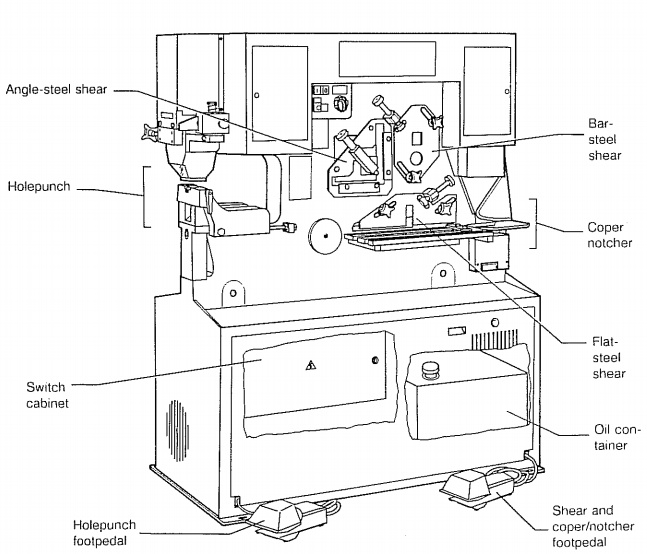

Introduction:These universal machines are supplied with standard tooling including repetition support tables at punch,shear and notch stations and with easily adjusted holddowns at all five work stations to safely control the operations.Comprehensive safety guards are fitted as standard on all work stations. Free standing on a suitable floor, they just require electrical connection to be ready for work. For two operator utilization , the hydraulic system is activated by two shielded foot controls, one operating the punch end cylinder, the other operating the shear end cylinder. The shear cylinder provides the power to the three shearing and the notch stations. The system gives accurate power inching at all five work stations and allows the machine to be stopped at any position giving safe and accurate tool setting and work positioning. Limit switches at both ends of the machine control stroke length at all stations. Centralised lubrication is metered by one-shot system, being only one feature of the low maintenance requirement. An optional 'Production Pack' is available to enhance the machine specification, this includes: 1 low volt halogen lamp on a movable magnetic base, 1.0 m long touch and cut ruled length stop,fine adjustment facility to the punch stroke and measuring scales in the notch table.

Features

- Large punch table with multi-purpose bolster - removable table block for overhang channel / joist flange punching.

- Punch table, shear table and notch table standard equipment

- Non-tiltable and as thus wear-free angle-cutting blades.

- Power inching and adjustable strokes at punch & shear end.

- Centralised pressure lubrication.

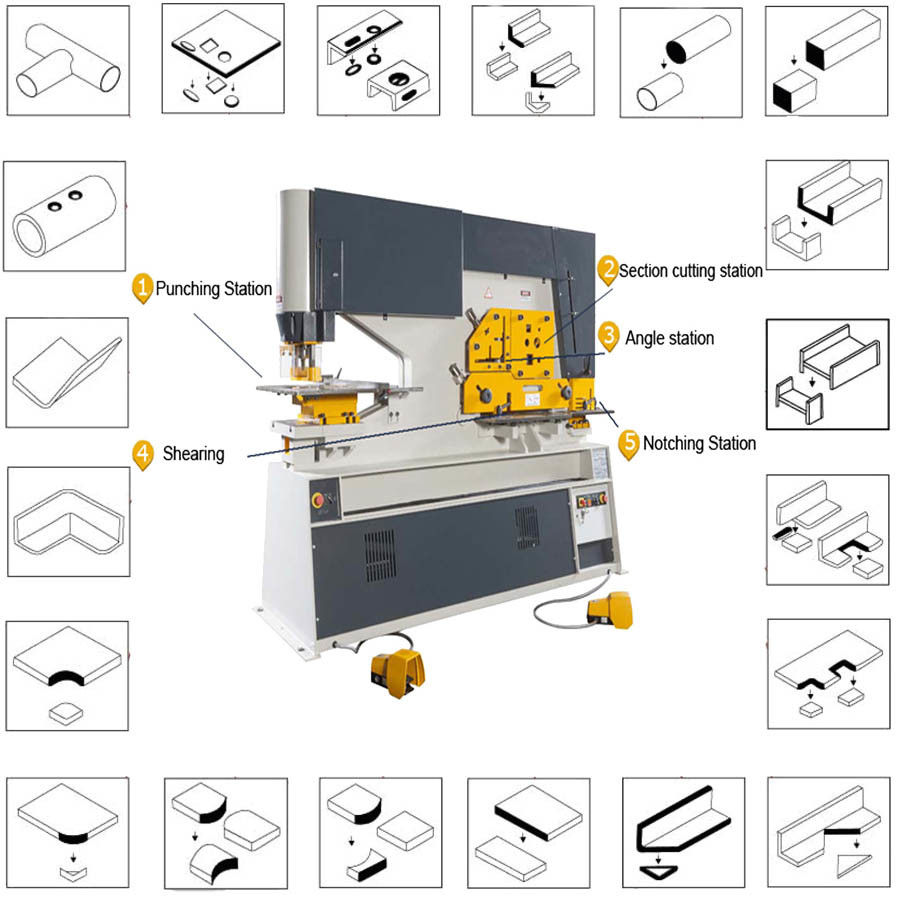

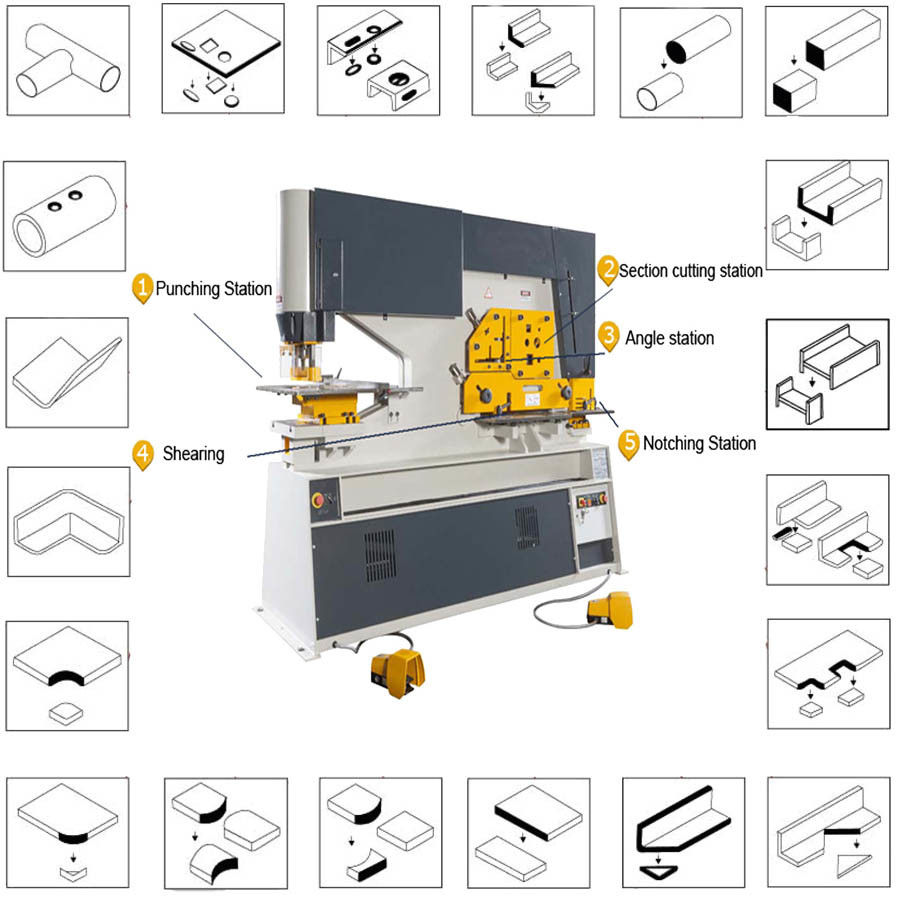

- Wide variety of applications - for large hole punching, crimping, tube notching, bar bending, sheet bending, punch press applications

- Large throat depth at the punching station - extra deep throat models available.

- Mitre cut flanges of angle under shear blade.

- Alternative rectangular/vee notching facility.

- Work station guards standard fitment.

- Two cylinder operation.

- Overload relief on hydraulic system.

- Interchangeable bearings, seals and valves readily available from

stockists of hydraulic equipment.

- Machines with very low maintenance requirements.

Application:

| MODEL | MULTI 60 | MULTI 70 | MULTI 80 | MULTI 95 | MULTI 125 | MULTI 175 |

|

| RATED CAPACITY | 60T | 70T | 80T | 95T | 125T | 175T |

| PUNCHING |

| Hole Punching(D x T) | 28x15 | 26X20 | 28X20 | 27X25 | 32X25 | 40X32 |

| Max. hole punching(D x T) | 57x8 | 57X9 | 57X10 | 57X12 | 57X16 | 57X22 |

| Stroke | 55 | 55 | 55 | 80 | 80 | 80 |

| Standard depth of throat | 305 | 305 | 305 | 355 | 355 | 625 |

| Extend depth of throat | 625 | 625 | 625 | 625 | 625 | 625 |

| Max. hole size | 57 | 57 | 57 | 57 | 57 | 57 |

| Max. hole size | 160 | 160 | 160 | 160 | 225 | 225 |

| Max. section steel | 305 | 305 | 305 | 305 | 305 | 380 |

| SHEARING |

| Max. thickness for plate | 230X20 | 300X20 | 300X20 | 380X20 | 380X25 | 380X30 |

| Max. width for plate | 375X10 | 375X15 | 450X15 | 480X15 | 600X15 | 600X20 |

| Cut corner in angle steel, Max. 45 degree | 100X15 | 100X15 | 100X15 | 120X15 | 120X15 | 125X15 |

| ANGLE CUTTING |

| 90° | 130X13 | 130X13 | 150X13 | 150X15 | 150X18 | 200X20 |

| 45° | 70X10 | 70X10 | 70X10 | 80X10 | 80X10 | 80X10 |

| SECTION CUTTING |

| Round steel/Square steel | 45 | 45 | 45 | 50 | 55 | 65/55 |

| Channel steel/H steel | 130X65 | 130X65 | 130X65 | 160X90 | 200X100 | 200X100 |

| T steel* | 90X12 | 90X12 | 90X12 | 100X12 | 120X12 | 150X15 |

| NOTCHING |

| Plate thickness | 10 | 10 | 12 | 12 | 12 | 16 |

| Width-rectangle | 45 | 45 | 40 | 52 | 60 | 60 |

| Depth-rectangle | 90 | 90 | 90 | 100 | 100 | 100 |

| Depth-V shape | 60 | 60 | 60 | 70 | 80 | 80 |

| Cut edge | 100X10 | 100X10 | 100X10 | 100X13 | 100X13 | 100X14 |

| CONER NOTCH |

| Max. corner cutting ability | 250X6 | 250X6 | 250X6 | 250X6 | 250X6 | 250X6 |

| TUBE NOTCH |

| Max. outside diameter for tube | 83 | 83 | 83 | 108 | 108 | 165 |

| BENDING |

| flat steel bending | 250X12 | 250X13 | 250X13 | 250X20 | 250X22 | 250X25 |

| plate bending | 500X3 | 500X3 | 500X3 | 500X3 | 700X3 | 700X4 |

| PUNCHING AT NOTCH STATION |

| Depth | 125 | 125 | 125 | 125 | 125 | 125 |

| Max. ability | 38X7 | 38X8 | 38X8 | 38X10 | 38X12 | 38X13 |

| TECHNICAL DATA |

| Power for main motor | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 |

| Net weight for machine | 1570 | 1620 | 1925 | 2730 | 3100 | 5550 |

| Machine size (L x W x H cm) | 164X71X178 | 164X71X180 | 190X79X191 | 190X79X191 | 200X80X203 | 270X112X216 |

Resource Sheetmetal Machinery is an international supplier focus on the sheet metal equipment and the solution.

Our offer includes CNC press brake, press brake, laser cutting machine, shearing machine, busbar machine, drilling machine, fastener insertion machine, folding machine, notcher machine, power press, production line as well as other different kinds of machine tooling and accessories.

What we are

-RSM offer you the preferential price and also professional service and technical support.

-We make the most reasonable modular and the specialized solution for your own productions.

-We are committed to create one-stop Chinese sheetmetal solution export base platform by network platform, VIP customer, product showroom.

Advantage

-Professional sheet metal sourcing partner

-Buffet mixed salad whole solution

-Famous factory Shanghai international representative office

-Attractive Price

-Guarantee quality

Service

-Help customers take very little time and effort to find the most suitable products easily.

-We respond quickly to customers and communicate effectively with them, which aims to make you find what you need as soon as possible.

-As a buyer's representative and partners, we avoid simply pursuit of short-term interests. We kown much about who has the advantage of specific technical. We give you sound advice.

We are your bridge to China, once you have decided, RSM will be your consultants and negotiators!