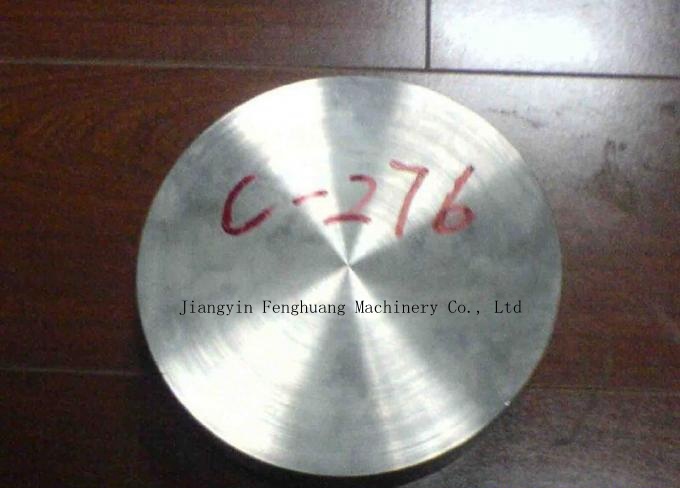

Hastelloy C-276

| UNS | Trademark | W.Nr |

| N10276 | HastelloyC276 | 2.4819 |

Hastelloy C-276 Chemical composition

| Alloy | % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S |

| C276 | Min. | balance | 14.5 | 15 | 4 | 3 |

|

|

|

|

|

|

|

| Max. | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.35 | 0.04 | 0.03 |

Hastelloy C-276 Physical properties:

| Density | 8.9 g/cm³ |

| Melting point | 1325-1370 ºC |

Hastelloy C-276 Alloy m inimum mechanical properties in the room temperature

| Alloy status | Tensile strength

Rm N/mm² | Yield strength

RP0.2 N/mm² | Elongation

A5 % |

| Solution treatment | 690 | 283 | 40 |

Hastelloy C-276 Characteristic

1.Excellent corrosion resistance to most of corrosion media in oxidation and reduction environments.

2.Excellent resist pitting, crevice corrosion and stress corrosion cracking performance.

Hastelloy C-276 Metallurgical structure

C276 is face-centered cubic lattice structure.

Hastelloy C-276 Corrosion resistance

C276 alloy suit for many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist the chloride corrosion, and tungsten make it corrosion resistance better.C276 is one of a few material that can resist the corrosion of most chlorine, hypochlorite and chlorine dioxide, this alloy have prominent corrosion resistance to high concentration chlorate( iron chloride and copper chloride).

Hastelloy C-276 Application field:

C276 is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system.This material especially suit for high temperature environment, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environment.

The digester and bleacher in the use of paper pulp and paper making industry.

Absorption tower, re-heater and fan in the FGD system.

The equipment and parts in the use of acidic gas environments.

Fenghuang Machinery Co is specialized in manufacturing of forgings for valves, oil-gasfield products and other mechanical parts, we are located in Jiangyin City which is a short two hours driving from Shanghai Port.

With complete manufacturing facilities and experienced technical staff, we are capable of supplying various forging materials, covering AISI, ASTM, EN and other global standards. Together with our advanced QC instruments and system, we ensure every product complies with our customer's technical requirements. After decades of accumulated experience, in addition to ordinary carbon steel, alloy steel, stainless steel, corrosion-resistant alloy, Heat-resistant alloy, Precision alloy and tool steel.

We take pride in both our quality and delivery reliability and through our knowledgeable staff we are always looking to improve our service and product offerings to valued customers.