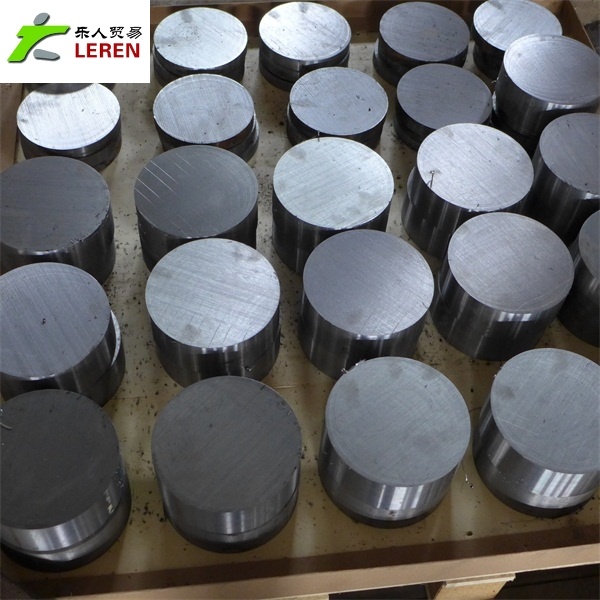

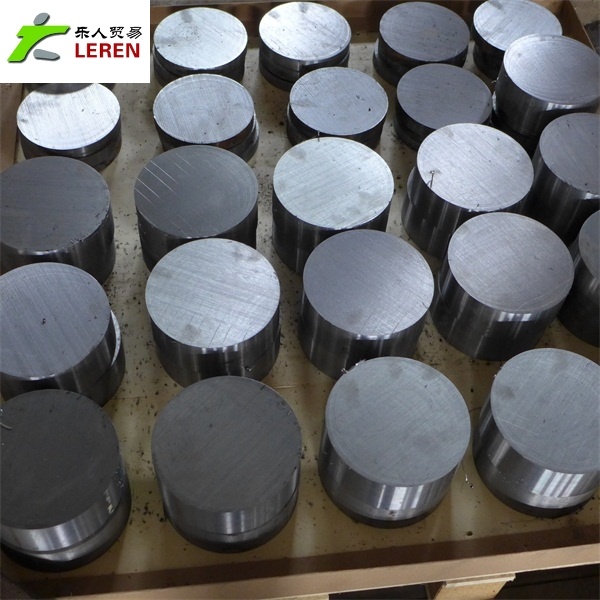

Forged Steel Round Bar AISI 1045 S45c 42CrMo/4140/En19 /40crnimo

| Price: |

Negotiable/Ton |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

10/Ton |

| Pay Type: |

L/C,T/T |

Forged steel round bar AISI 1045/CK45/S45C/S35C/4140/4150

Forging steel bar to make forged parts or forging ring1.Chemical Composition (%):| Grade | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo4 | 0.38-0.45 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.90-1.20 | 0.15-0.25 |

| 1.7225 | 0.38-0.45 | ≤0.40 | 0.60-0.90 | ≤0.025 | ≤0.035 | 0.90-1.20 | 0.15-0.30 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| Grade | C | Si | Mn | P | S |

| 1035 | 0.32-0.38 | 0.15-0.35 | 0.60-0.90 | Max 0.030 | Max 0.030 |

| 1045 | 0.43-0.50 | 0.15-0.35 | 0.60-0.90 | Max 0.030 | Max 0.030 |

| 1050 | 0.48-0.55 | 0.15-0.35 | 0.60-0.90 | Max 0.030 | Max 0.030 |

| 1055 | 0.50-0.60 | 0.15-0.35 | 0.70-1.00 | Max 0.030 | Max 0.030 |

| 1522 | 0.18-0.24 | 0.15-0.35 | 1.10-1.40 | Max 0.030 | Max 0.030 |

| 1524 | 0.19-0.25 | 0.15-0.35 | 1.35-1.65 | Max 0.030 | Max 0.050 |

| 1541 | 0.36-0.44 | 0.15-0.35 | 1.35-1.65 | Max 0.030 | Max 0.050 |

2.Available sizes:Round: Dia. 10 - 1000mm20mm-300mm with hot rolled supply condition;200-1000mm with forged supply condition3.Delivery condition: Hot rolled or forged, Peeled or black surface, annealed or QT.4.Applications:Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears.5.Heat Treatment:Soft annealing: heat to 680-720°C, cool slowly.Hardness after annealing: Max. 241 HBHardening: 820 - 850 °CNormalizing temperature: 840-880°CTempering: 540-680°C6. Inspection: 100% Ultrasonic according to the test standards:SEP1921-84,GR.3 CLASS C/C 7. Packing situation: standard seaworthy packing or as customer required8. Delivery time: 30 days after order confirmed 9. Process: EAF+LF+VD ( necessary) +UT+ Peeled(optional) +Turned (optional) + Heat Treatment (optional)

10.Other gradescomposition

| Steel grades | C | Si | Mn | Cr | Mo | Ni | P | S | V | w |

| Carbon Structure Steel | Q235(B)/SS400/S235JR/A36 | ≤ 0.20 | ≤0.35 | ≤1.4 | 0.3-0.4 |

| ≤0.30 | ≤ 0.045 | ≤ 0.045 |

|

|

| 20#/CK22, CK20/1020/050A20/S20C | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | 0.3-0.4 |

| ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| 45#/CK45, C45/1045/080M46/S45C | 0.42-0.5 | 0.17-0..37 | 0.5-0.8 | 0.3-0.4 |

| ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| Alloy Structure Steel | 20Cr/20Cr4/5120/527A19/SCr420H | 0.18-0.24 | 0.17-0.37 | 0.50-0.80 | 0.70-1.00 | ≤0.15 | ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| 40Cr/41Cr4/5140/520M40/SCr440 | 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | 0.8-1.1 | ≤0.15 | ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| 30CrMo/4130/1717COS110/SCM420 | 0.26-0.34 | 0.17-0.37 | 0.4-0.7 | 0.8-1.1 | 0.15-0.25 | ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| 35CrMo/34CrMo4/4135/708A37 | 0.32-0.40 | 0.17-0.37 | 0.4-0.7 | 0.8-1.1 | 0.15-0.25 | ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| 42CrMo/42CrMo4/4140/708A42/708M40 | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | 0.90-1.2 | 0.15-0.25 | ≤0.30 | ≤ 0.035 | ≤ 0.035 |

|

|

| 8620H | 0.17-0.23 | 0.15-0.35 | 0.65-0.95 | 0.35-0.65 | 0.15-0.25 | 0.35-0.75 | ≤0.025 | ≤ 0.035 |

|

|

| 40CrNiMoA/40CrNiMo22/4340/871M40/SNCM439 | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.60-0.90 | 0.15-0.25 | 1.25-1.65 | ≤ 0.025 | ≤ 0.025 |

|

|

| Spring Steel | 55Si2Mn/55Si7/9255/250A53/SUP6 | 0.52-0.60 | 1.50-2.00 | 0.60-0.90 | ≤0.35 |

| ≤0.35 | ≤ 0.035 | ≤ 0.035 |

|

|

| 60Si2MnA/65Si7/9260/250A61/SUP7 | 0.56-0.64 | 1.60-2.00 | 0.70-1.00 | 0.3-0.4 |

| ≤0.35 | ≤ 0.025 | ≤ 0.025 |

|

|

| 50CrVA/50CrVA/6150/735A50/SUP10 | 0.47-0.54 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | ≤0.15 | ≤0.30 | ≤ 0.025 | ≤ 0.025 |

|

|

| GCr15/100Cr6/E52100/534A99/SUJ2 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | ≤0.10 | ≤0.30 | ≤ 0.025 | ≤ 0.025 |

|

|

| Bearing Steel | 52100 | 0.93-1.05 | 0.15-0.35 | 0.25-0.45 | 1.35-1.60 | ≤0.10 | ≤0.25 | ≤ 0.025 | ≤ 0.015 |

|

|

| Cold Working Die Steel | CrWMn/105WCr6 | 0.9-1.05 | ≤0.40 | 0.8-1.1 | 0.9-1.2 |

|

| ≤0.030 | ≤0.030 |

| 1.2-1.6 |

| 9Mn2V/O1/SKS3/105WCr6 | 0.85-0.95 | ≤0.40 | 1.70-2.00 |

|

|

| ≤0.030 | ≤0.030 | 0.1-0.25 |

|

| Cr12/D3/SKD1/X210Cr12 | 2.00-2.30 | ≤0.40 | ≤0.40 | 11.5-13.0 |

|

| ≤0.030 | ≤0.030 |

|

|

| Cr12Mo1V1/D2/SKD11/X165CrMo12V | 1.40-1.60 | ≤0.60 | ≤0.60 | 11.0-13.0 | 0.70-1.20 |

| ≤0.030 | ≤0.030 | 0.5-1.1 |

|

| Hot Working Die Steel | 5CrNiMo/l6/skt4/55CrNiMoV2 | 0.5-0.6 | ≤0.40 | 0.5-0.8 | 0.5-0.8 | 0.15-0.30 | 1.40-1.80 | ≤0.030 | ≤0.030 |

|

|

| 4Cr5MoSiV1/H13/SKD61/X40CrMoV51 | 0.32-0.45 | 0.8-1.20 | 0.2-0.5 | 4.75-5.5 | 1.10-1.75 |

| ≤0.030 | ≤0.030 | 0.8-1.2 |

|

| 4Cr5MoSiV/H11/SKD6/X38CrMoV51 | 0.33-0.43 | 0.8-1.20 | 0.2-0.5 | 4.75-5.5 | 1.10-1.60 |

| ≤0.030 | ≤0.030 | 0.30-0.60 |

|

| 3Cr2W8V/H21/SKD5 | 0.3-0.4 | ≤0.40 | ≤0.40 | 2.2-2.7 |

|

| ≤0.030 | ≤0.030 | 0.2-0.5 | 7.5-9.0 |

| Plastic Die Steel | 45-55/1045-1055/S45C-S55C/C45-C55 | 0.42-0.5 | 0.17-0..37 | 0.5-0.8 | 0.3-0.4 |

| ≤0.30 | ≤ 0.030 | ≤ 0.030 |

|

|

| 40Cr/5140/SCr440/41Cr4 | 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | 0.8-1.1 | ≤0.15 | ≤0.30 | ≤ 0.030 | ≤ 0.030 |

|

|

| 3Cr2MoV/P20/40CrMnMoS36 | 0.28-0.40 | 0.20-0.80 | 0.60-1.00 | 1.4-2.0 |

|

| ≤0.030 | ≤0.030 |

| 0.3-0.55 |

| 3Cr2NiMnMo/P20+Ni/PDSSS/2738 | 0.32-0.40 | 0.2-0.4 | 1.10-1.50 | 1.7-2.0 | 0.25-0.40 |

| ≤0.030 | ≤0.030 |

|

|

11.

Our mill is the frist batch of Chinese metallurgy industry through the ISO9002qualitysystem,ISO14001environmental management system and OHSAS18001 occupational safety and health management system. The mill possesses a perfect quality control network,the quality from material to products being kept under close monitoring.On-line equipped are over 30sets of advanced dtedcting instruments introducted from Germany,Japan,Switzerland,Holland and other counteirs,including SPECTROLAB M9 direct-reading spectrograph,EMTA-620 infrared carbon&sulphur analyzer,STMUTTTX10 XRF,EMGA-620 nitrogen-oxygen measuration equipment,microscope and image analyzer,both our detecting equipment and detecting operation reaching the advanced levels at home. 11.Our service

Contacts person:Ms.Sunny Sun S-kype:sunny88962

| Prod Model: |

Dia: 200mm-1000mm |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Name Of Products: |

Forged Steel Round Bar |

| Products Material: |

Alloy or Carbon Forged Steel Round Bar |

| Grade: |

S45c S35c 4140 4150 8620 4340 etc. |

| Diamteter: |

200mm-1000mm |

| Length: |

1000mm-10000mm |

| Supply Condition: |

Forged+Q+T |

| Delivery Condition: |

Black Surface or Black Surface |

| Key Words: |

Forged/Forging |

| Delivery Time: |

10-20days |

| Processing Object: |

Metal |

| Molding Style: |

Forging |

| Heat Treatment: |

Q+T |

| Surface Treatment: |

Black or Rough Machine |

| Standard: |

AISI/ASTM/DIN/GB/JIS |

| Molding Technics: |

Hot Forging |

Qingdao Helio Steel Co., Ltd. Was established in March19, 2012. Our company's business staff members possess professional service capabilities of steel products, with more than a decade of experience on steel production, technology development, product sales and foreign trade. We comply the principle of friendly cooperation and mutual benefit, and persist in developing together with new and old customers.

Our company is located in Qingdao, a coastal city of Shandong Province, which is near Laiwu Steel Group. Only Laiwu City has steel production capacity of 20 million tons each year. Meanwhile, it is also the largest production base of powder metallurgy products in the whole country. Otherwise, there are more than ten well-known steel manufacturers within the province and the surrounding areas, so steel resources here is abundant and we can meet customers' various requirements.

Our company is mainly engaged in steel products for various specifications and materials, such as continuous casting billets, continuous casting tubes, hot-rolled bars, tubes, hot-rolled square steel, flat steel, H section steel, hot-rolled coils, cold-roll large-size panels, forging materials, and forgings.

We also run the import and export of steel products, based on the needs of customers at home and abroad to develop a variety of special steel products and timely delivery. I hope to sincerely cooperate with domestic and foreign customers, providing high-quality and low-priced products and professional services.