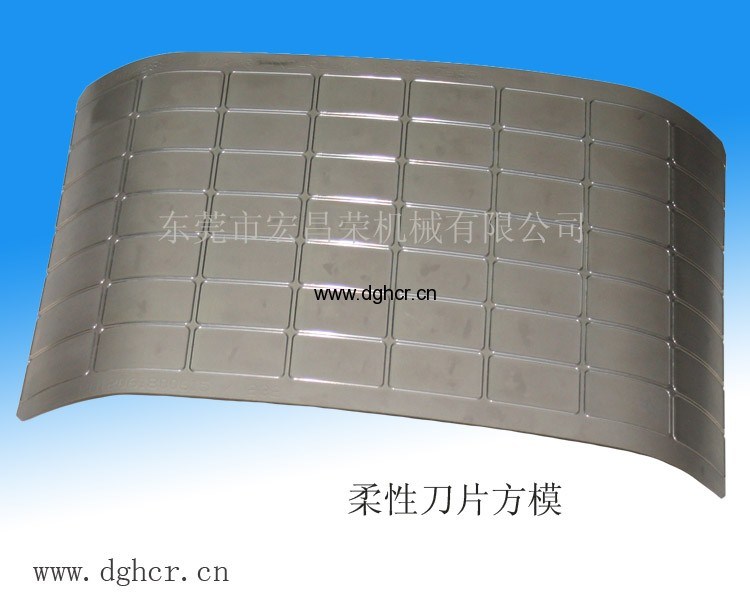

Flexible Die, also known as flexible version, rotary die-cutting version or knife skin equiped on magnetic roller is cost-effective tool in connection rotary die-cutting.

Flexible Die from HCR utilizes top quality steel imported from Europe, going through rigid chemical milling then to be finished by CNC machining. There is no human touch to sharpen or amend blades. Blade height can be controlled within a few microns to designed TPH. Blade to blade distance can also be controlled precisely within requested tolerances, to meet the growing stringent requirements from label printing industry, in particularly from the electronic label segment. Flexible Dies from HCR are treated with special surface coating to ensure anti-rust and durability.

Applications

The vast majority of adhesive cylinder label products like high-grade cosmetic label, ordinary bar code label and supermarket label can be rotary die-cutting by cost-effective flexible die. The angle and height of Flexible die can be adjusted to fit the different paper and body paper of material even complex shaped electronic label or thick cardboard. Flexible Die also can be used with magnetic roller with special specifications to complete on-line processing. Compared with carving knife, flexible die is more accurate and easy to be made, the cost is relatively low.

Compared with flat knife, the die-cutting trace on adhesive body paper is more uniform.

Technical Specifications

1. The height of flexible die can be adjusted to fit different material in design, the height of die within the scope of 3 microns ensure uniformity of die-cutting.

2. The angle of Flexible die can also be adjusted to fit different material in design, to achieve balance of die-cutting and extend the life of tool.

3. Flexible Die with special design can also be applied in continuous cutting work.

Flexible Die can be designed double knives of high cutting, folding, dotted and micro line according to customer needs.

Unique Features

Flexible Die from HCR use special surface coating technology to strengthen ability of anti-rust and anti-corrosion, the hard surface can prolong service life. Flexible Die also perfectly combined the advantages of high quality of die cutting and the effective control of cost. According to different needs of customers the highest cutting can do 25 to 60 wire. To cut different label paper and colloid, laser hardened knife processing technology is more durable. Delivery within 7 working days.

Information of order flexible die To provide: (1)model of rotary (2) data of magnetic roller, including the teeth of gear, the diameter of shoulder and body (3)pattern of cutting, cutting line graph is finished graph after the cutting shape graph. If the cylinder die-cutting is put on the surface of materials, the line chart on knife version is a mirror of shape graph; (4) details of cutting material. There are several ways to tell the supplier details: (a) material supplier number and material list, (b) the type and thickness of surface sheet and bottom sheet (c) send a roll of material to us.

Dongguan Hong Changrong Machinery Co., Ltd. Was founded in 2007, is a high-tech company specializing in the production of rotary die, dedicated to the wheel and mold production of narrow printing and demand of processing industry in China. Company is located in the national famous hardware, machinery and mold Town --Changan of Dongguan City, Guangdong Province. Only 10 minutes to the Guangzhou-Shenzhen highway and Changan crossing, 25 minutes to Shenzhen International Airport, the traffic is very convenient.

Hong Changrong machinery adopts advanced technology and raw material from European, with the precision and rigorous technology, specialize in producing magnetic roller, print roller, cutting roller, pneumatic roller, print roller shaft, magnetic platform, screen head, cylinder die-cutting seat, anvil roller and provide a series of service of knife mold repairing. Agent of German Wink Die. Its products and services have been widely recognized by customer. Hong Changrong machinery adhering to the principle of "customer first, forge ahead, innovation" provide quality service to customers.

As for new customers, the company giving the optimal scheme of mold design and provide timely technical service when use to ensure customers use the optimal rotary mold. To ensure the quality of products, the company adhere to use high-quality raw materials and components imported, high-precision manufacturing equipment, strict control of each link in the production, guarantee long-term stability of the product. The operation of company based on two shifts per day to ensure customer delivery requirements and can work overtime according to requirements to ensure that customers are not affected.

To The Pearl River Delta region, we can provide service on-site, outside of province we give help by express, logistics which ensure the interests of customers and maintain long-term friendship. Because of these we obtained more and more recognition and trust from customers. We sincerely hope to cooperate with that of noble aspirations, also hope our friends put forward views and good suggestions. Let Hong Changrong continue to grow in expectation of everybody!