Five Axis Horizontal Boring and Milling CNC Machining Center

| Price: |

Negotiable/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T |

Five Axis Horizontal Boring and Milling Machine CenterHigh Torque,High Precision,High RigidityHigh Torque·Spindle motor 37(continuous)/45(30min) KW super power.

·Maximum torque output 2500Nm (260kgf-m),the highest specifications for this class.

·The nose type spindle head can be close to the workpiece,which is suitable for heavy cutting.

·Rotary table can carry 10000-25000kg.

·Z axis can be continuously subjected to the axial load of 2000kgf,to ensure high torque and high speed to provide high speed to provide high cutting force. High torque gear headstockHigh Precision·Spindle bearing with oil mist lubrication ,surrouding and with the tubing jacket cooling design avoids thermal displacement problems.

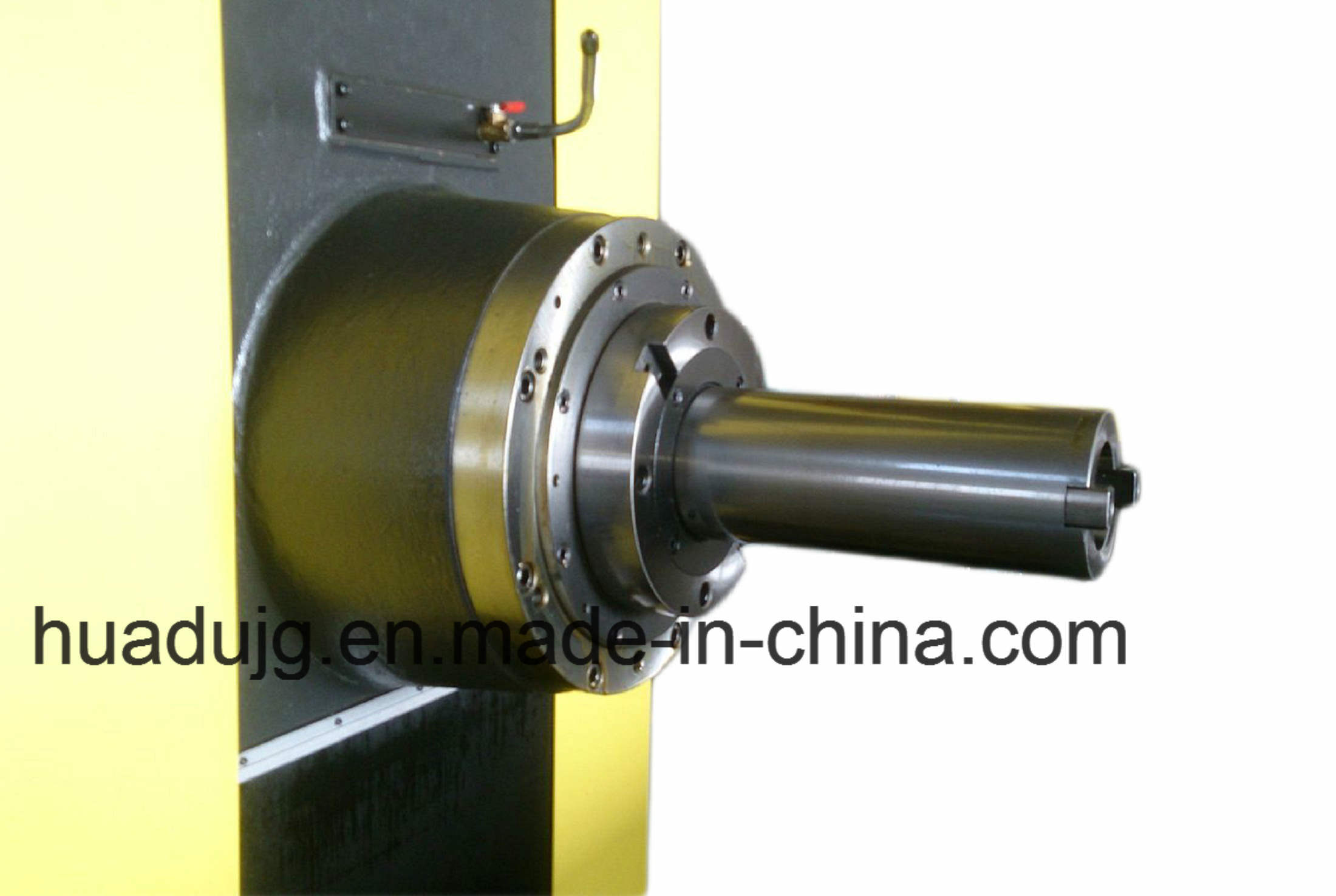

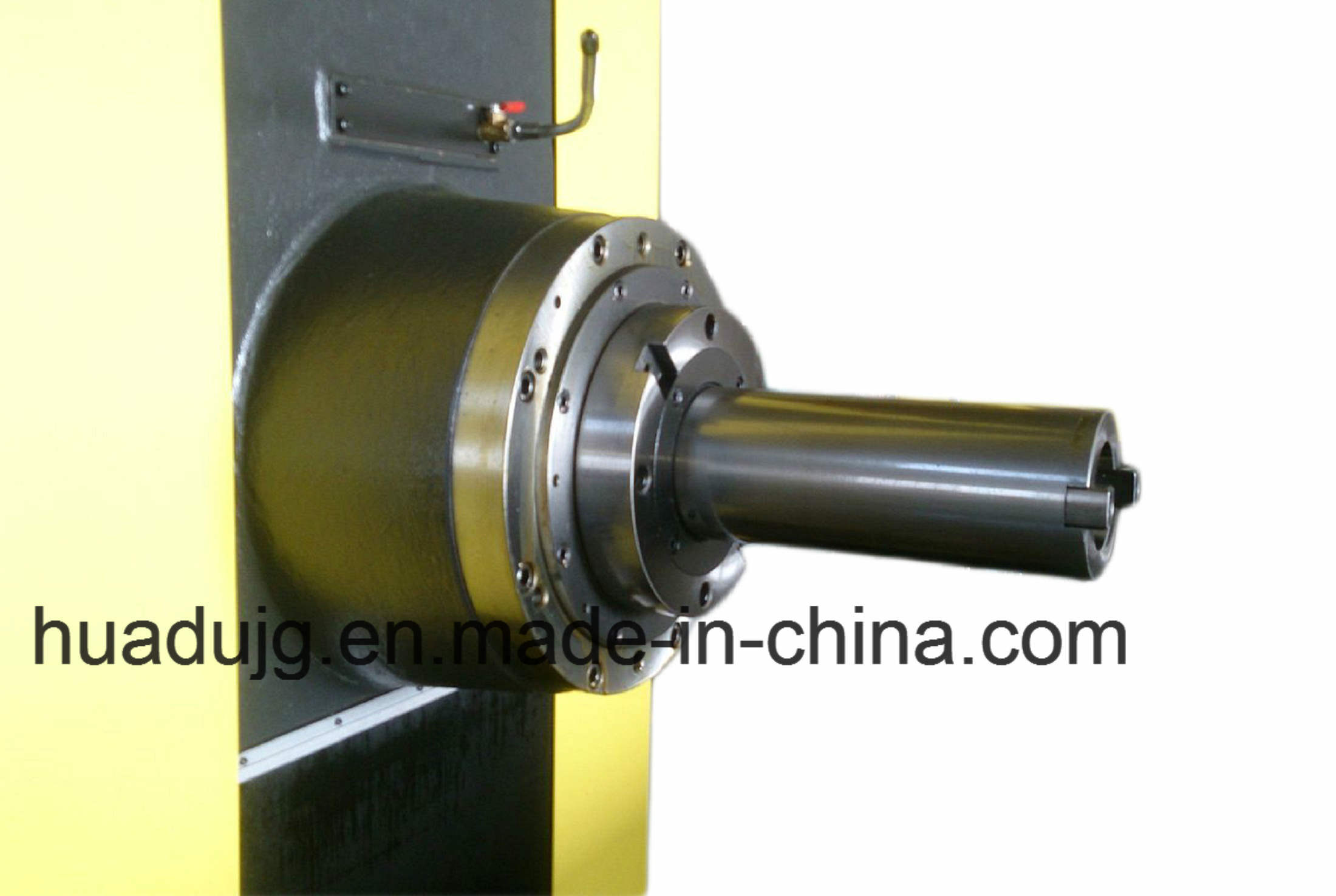

High torque gear headstockHigh Precision·Spindle bearing with oil mist lubrication ,surrouding and with the tubing jacket cooling design avoids thermal displacement problems.

·The flange portion of the spindle motor jacket cooling using tubing.

·Spindle with a special nitriding treatment ,used for many years and no wear.

·X/Y-axis rail screw and motor using Derect-drive without backlash mechanism.

·No overhanging phenomenon when the table moves.High Rigidity·Casting structure composed of stability,strong vibration resistance and strong senior cast iron with crch-type structure of high rigidity.

·Column resistance to bending ,torsional rigidity enhance 1.7 times,in the uppermost end Y-axis travel can also be stable machining.

·The combination of the nitride,cryogenic(-190ºC) spindle and the high precision,high rigidity spindle bearings ,can play the best long-term performance. Precision rotary table(double worm)HEADBoring axis adopts Germany imported materialSACM-645,after nitrogen treatment hardness up (HS100°±10°), and increase the wear resistance by streching cryogenic (-190ºC)aging treatment; spindle can be extended to 500-700mm long,suitable for deep processing.COLUMN(Patented Structure)High quality Meehanite cast iron ,the structure of high stength arch bridge is used in the internalstructure of the column.To increase the rigidity of the column to 27%,two electric furnace failure and vibration failure,to ensure that the seismic and long-term no deformation.

Precision rotary table(double worm)HEADBoring axis adopts Germany imported materialSACM-645,after nitrogen treatment hardness up (HS100°±10°), and increase the wear resistance by streching cryogenic (-190ºC)aging treatment; spindle can be extended to 500-700mm long,suitable for deep processing.COLUMN(Patented Structure)High quality Meehanite cast iron ,the structure of high stength arch bridge is used in the internalstructure of the column.To increase the rigidity of the column to 27%,two electric furnace failure and vibration failure,to ensure that the seismic and long-term no deformation.

ROTARY TABLE(Patent)All-area support of hydraulic fracturing design,unique twin-turbo without backlash drive,six columns tightening force at any angle up to 13500kg/cm²,cylinder lock with 90-degree pin alignment.Specification

| HBM-110T2 | HBM-110T3 | HBM-130T3 |

| Travel |

| X/Y/Z Axis Travel | 2800/1800/1500mm | 3000/2100/1500mm | 3000/2100/1500mm |

| W-axis diameter/peojecting | 110/500mm | 110/500mm | 120/700mm |

| Spindle center to table | 0-1800mm | 0-2100mm | 0-2100mm |

| Line Guideway |

|

|

|

| Table |

| Worktable size | 1440mm*1600mm | 1440mm1600mm | 1440mm*1600mm |

| Max.loading of worktable | 8000kg | 8000kg | 8000kg |

| Degree Minimum division | 0.001° | 0.001° | 0.001° |

| Spindle |

| Spindle taper/Rivet | BT50-45° | BT50-45° | BT50-45° |

| Power of spindle motor | 22/26 | 22/26 | 22/26 |

| The number of revolution and gear | Full gear 2500 continuous Variable Speed |

| Fast Process |

| X/Y/Z Axis Rapid Feed Rate | 10000mm/min | 10000mm/min | 10000mm/min |

| B Axis rotation speed | 1r/min | 1r/min | 1r/min |

| W Axia Rapid Feed Rate | 4000mm/min | 4000mm/min | 4000mm/min |

| Min.set unit & moving unit | 0.001mm | 0.001mm | 0.001mm |

| Procesion |

| Positioning accuracy(JIS) | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Repeatability accuracy(JIS) | ±0.003 | ±0.003 | ±0.003 |

| Tool Magazine |

| Tool magazine | 60 | 60 | 60 |

| Electric |

| Standard Control System | FANUC 0IMD | FANUC 0IMD | FANUC 0IMD |

| Feed Motor | 7,7,7,4,4KW | 7,7,7,4,4KW | 7,7,7,4,4KW |

| Power capacity | 70KVA | 70KVA | 70KVA |

| Size |

| Machine Height | 3800mm | 4100mm | 4100mm |

| Area Covered | 7500mm*7800mm | 8500mm*7800mm | 8500mm*7800mm |

| Machine Weight | 26000kg | 26000kg | 32000kg |

| Prod Model: |

HBM-130T3 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia |

| Wight: |

32000kg |

| Rotary Table Dimensions: |

1440*1600 |

| Nc System: |

Fanuc |

| Process Usage: |

Metal-Cutting CNC Machine Tools |

| Movement Method: |

Contour Control |

| Control Method: |

Closed-Loop Control |

| Numerical Control: |

CNC/MNC |

| Performance Classification: |

High-End CNC Machine Tools |

| Processing Precision: |

0.01mm |

Our company supplies different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

"Huadu Precision" is a die set industrial leader, Mr. Xiangbin founded in A. D. 2004, the company partners adhering to the "produce high-end machine tools, strengthen national industry, casting manufacturing powerhouse" as own duty.

Company through joint venture merger overseas brands, with the management idea "integrity and efficient, the value of sharing" and collected dozens of domestic and overseas research and development, sale, mechanical and electrical integration type of elite talent. We committed to manufacture the numerical control machine tools with "steady, accurate, fast, beauty, wisdom""Huadu Precision" has rapidly in some industries developed and into the "Made in China" brand among the forefront of high-end CNC machine tool and the user preferred standards.

Our company invested nearly 500 million yuan($80 million, ), covers about 100 acres, having tens of thousands of square meters of modern factory building. We have imported a batch of ultra-precision industrial machines from Japan and Taiwan; Formation in kunshan Precision and dongguan Precision, as the main body of the two major manufacturing bases;

The main products include: Horizontal boring and milling machining center, dynamic column type precision horizontal machining center, CNC horizontal open box machine, gantry machining center and so on four big series. Products are widely used in automotive, mold, valves, machinery, energy and other industries.

"Huadu Precision": Adhere to the "strictly selected high-quality materials, strict enforcement of craft, strict buy first-class accessories, never cut corners, " the quality policy. Adhere to continuous improvement, constant innovation, obsessed with the details of the "spirit of craftsman", let China's CNC equipment really achieve world-class level.