1. ISO9001: 2008: Certification Since 2007. Nov

ISO/TS16949: 2009: Certification Since 2007. Nov

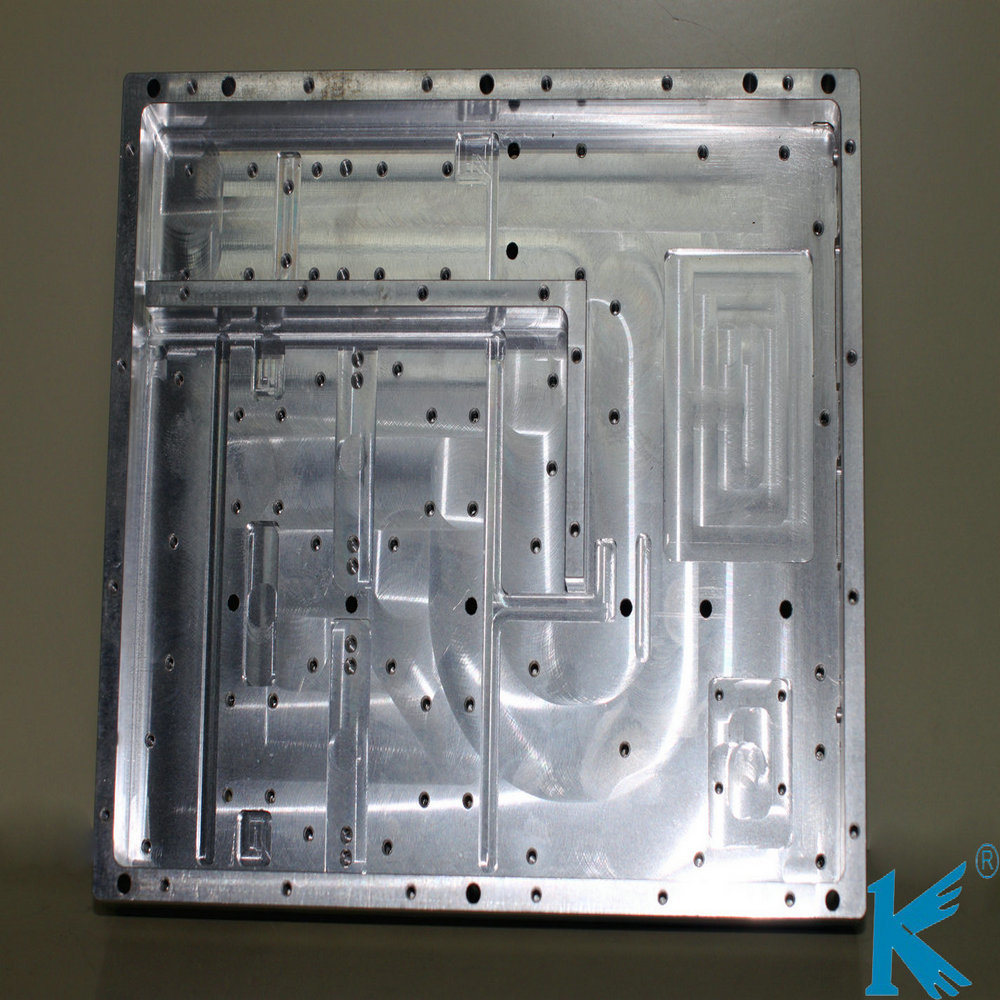

2. As drawings or samples or special requirements from customer like Faceplate Die Casting

3. We are experienced of OEM manufacturer for various kinds of OEM Metal Stamping Parts

4. Heat Treatment: According to customer's requirements for the Precision Parts

5. Packing: Crate, carton, wooden case, pallet according to clients' require;

6. Finish: Zinc Plated, chrome plated, powder coating, hot-DIP galvanized, electrophoresis or others;

7. Surface treatment: Polishing, zinc plating, nickel plating or chrome plating, phosphating etc

8. Part size: Diameter from 0.5mm to 150mm

9. Tolerance: Can be kept in +/-0.01mm

|

Product Name |

Faceplate Die Casting |

|

Material |

Brass /zinc /aluminum /carbon steel /stainless steel |

|

Specification |

As your request & drawings |

|

Process |

Forging/ milling /polishing /Painting /anodizing /brushing /casting /assembling /inspecting |

|

Color |

Golden /black metal /Shiny silver /anti-brass /anti-copper /chrome and etc |

|

Function |

Widely used in Machine Parts/Compressor /Auto Industry |

|

Quality control |

Strictly quality control in every production process |

|

Equipments |

Stamping machines /Auto-turning machines /CNC-turning machines /Milling machines /Drilling machines /kinds of Lathes /Testing equipments |

|

Main products |

Precision Machined Parts / CNC Machined Parts / Machinery Spare Parts /Auto Parts / Brass Fittings

Oil Plugs /Oil Level Indicators / Gear Boxes / Speed Reducers

Kinds of Valves / Bib cocks /Taps /Pipe Fittings / Tee Fittings / Vent Plugs |

|

Advantages |

More than 10-years' experience in precision hardware products

Certification : ISO9001: 2008; ISO/TS 16949: 2009

Factory Price /Superior Quality /Professional Service /Punctual Delivery

|

G.T.L Precision Technology (Shenzhen) Co., Ltd., specializes in research and development of high-tech precision hardware and fittings.With the rapid expansion of our business, G.T.L P Precision Technology (Shenzhen) Co., Ltd was set up in Shenzhen in 2002 as our first entity organization in the mainland.BEST Precision technology Co., Ltd is our Group export company in Shen Zhen, China.

As equipment plays a primary role in the production of any industry, we have successively introduced high-effective and high-tech machines in hardware industry from Japan and Taiwan to further our fully-equipped factory.Now we boast CNC processing centre and many kinds of digital control machine tools, including lathes, milling machines, plan grinding machines, internal and external cylindrical grinding machines, slow linear cutting machine and fast linear cutting machine and inspection machines with a processing precision up to ±0.002mm.Our efforts are dedicated to the production of precise CNC lathe works, rivet joint fasteners and inserts for a wide range of products including IT, auto fittings, audio and video equipment, sport equipment, computers, electric and electronic equipments, digital cameras, toys, illuminations, electric irons, cash registers, fishing kits, switches of air-conditioners, sanitary fittings, plastic and hardware, and mini motors, etc.

G.T.L is well standardized with normative and perfect quality control department as well as professional expertise technicians.All of the employees carry out each working procedure carefully in order to provide customers with satisfactory products and considerate service.To make sure that the tiny hardware plays its designated important role in the development of science and technology for human beings, we will perfect our skills constantly and make even greater efforts with perseverance to pursue our set goal of "Small hardware, big science".

It's the common pursuit of G.T.L employees that we will base ourselves on quality and people oriented products and constantly improve the quality to a higher level.