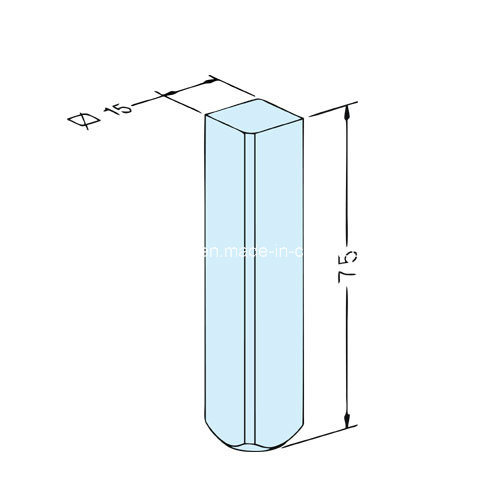

EDM Square 15 Electrode Shaft for mould discharge machining (3A-009866)

Detailed description:

1. Version: Set of 40 blanks. Drawn steel

2. To solder or bond to copper or graphite electrode blanks

3. Can be used on EDM/wedm for precision machine.

Our products advantage:

Fast: Clamping in seconds. The way of clamp traditional manual lock clamp greatly reduce manual work and save time.

Save: Save aligment of processing suitable for variety and special workpiece processing achieve free preset and detection on outside.

Precision: Unique standard interface precision repeat locating.

Our company advantage:

We has the advanced production facility such as JUNG form

Grinding machine and ELB highprecision surface grinding machine of Germany, MOORE jig grinding

Machine of USA, internal and external grinding machine and thread grindingmachine of Switzerland, and

OKUMA machining center andTSUGAMI numerical controlmachine of Japan.

Delivery time:

1-3days for sample order, 3-7days for official order

Why choose us?

1. The lowest production cost.

2. Flexible production plan.

3. Better quality production

If you interested our products, please feel free to contact me

Mobile: +8618038003166

| finished size | 25*25*50mm |

| Version | : Set of 40 blanks. drawn steel |

| Application | To solder or bond to copper or graphite electrode blanks |

Shenzhen Jingzuan Precision Hardware & Tools Co. Ltd was established in 2000 and specialized in designing, manufacturing and sales of 3A fast positioning JIG system, zero point system, ball lock shaft system and all kinds of un-standard JIG, numerical control machine collet chuck, guide sleeve, and etc machine tool accessories. Shenzhen company covers an area of 3, 000 square meters.

The company has the advanced production facility introduced from Germany, Switzerland, the USA and Japan, such as JUNG form grinding machine and ELB high-precision surface grinding machine of Germany, MOORE jig grinding machine of USA, internal and external grinding machine and thread grinding machine of Switzerland, and OKUMA machining center and TSUGAMI numerical control machine of Japan. The company established constant-temperature grinding room of 20± 0.5º C and high-precision constant temperature measuring center, and introduced high-precision measuring equipment, such as German ZEISS coordinate measuring machine, NIKON V-16A projector, ZEISS tool microscope and TESA MICRO-HITE altimeter. The stable quality and high cost performance ratio are highly appreciated by domestic and overseas customers.

Our comapny fully implemented ISO 9001 quality management system and is a great asset to highquality products of the company.