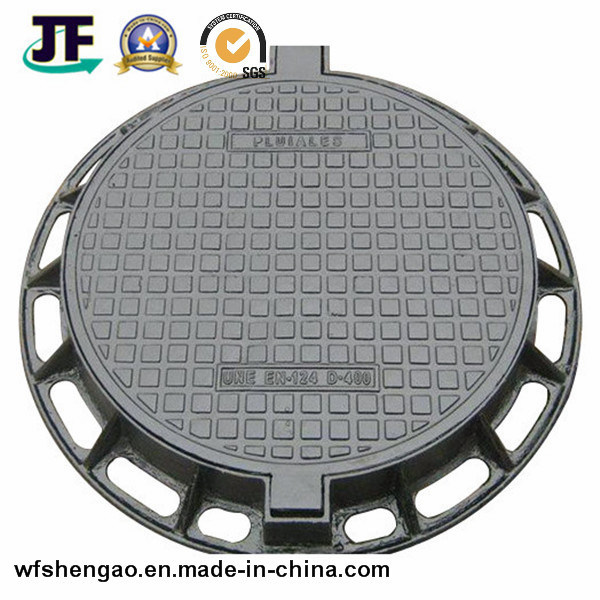

Ductile Iron Round Manhole Cover/Composite Manhole Cover for Septic Tank

1. Against theft ---WEIFANGSHENGAO Manhole Cover with shockproof rubber sealing is non-metallic, non-conductive and non-sparking, has no value of recycling, completely solving the theft problems.

2. High load capacity ---Its main components are fibreglass and unsaturated resin. JINMENG's existing moulds load capacity are A15, B125, C250, D400, E600.

3. Free design---Such as Color, Logo, Panel, Load and Dimension can be desigened according to the requirements of customer.

4. Long life ---Minimum lifespan is 30 years free of maintenance .

5. Well sealed ---It can be installed hermetically, and effectively prevent poisonous gases leaking out from cesspool. and no noise pollution or rebound.

6. Good wear and corrosion resistance ---It will never rust because it has good wear and corrosion resistance.

7. High and low temperature resistance ---Excellent insulator ( from-40°C~200°C)

8. Lighter weight and more competitive price--- the weight of composite manhole cover especially SMC manhole cover is lighter. The composite manhole cover is more convenient to transport, install and repair.

2. Application:

(1) Electric power pipeling well; Post, telecommunication, communication pipeline well;

(2) Street lamp well, fire control well, all kinds of valve well;

(3) City water, drainage pipeline well; Heat supplied, gas well;

(4) Anti-corrosion project, open ditch; It as well as can be made according to customers requirements.

Specifications

1.Process: Sand Casting, Investment Casting (Precision Casting/Lost-Wax Casting).

2.Casting experience: 10years,OEM service available

3.Surface: blackening, galvanize, plating,painting,etc.

4.Material: QT, iron, steel

5.Technology: sand casting

6.Advantages: Delivery on time, according to the demand for materials

7.Packing: wooden case or as your requirement.

8.Deliverywithin 20 days after receiving last confirm information.

9.Production Capacity: Sand Casting 2000 tons per month,Investment Casting 120 tons per month.

10.Certification: ISO 9001:2008.

2)Manufacturing process

1.Sample or Drawing by customer

2.Tooling proposal&Discussion

3.3D Tooling Design

4.Tooling production

5.Rough parts manufacturer

6.CNC Machining

7.Fitting&Finish

8.Tooling Measurement&Check

9.Assembly

10.Trial Production

11.Correction

12.Final Trial

13.Samples Inspection

14.Sample Approval by customer

15.Tooling Approval

16.Ductile iron sand casting

2)Company Profile:

We mainly undertake the casting parts,machined parts and other products.Our Import and Export Department have many years experiences of foreign trade,products are mainly exported to the United States,Denmark,Italy,Russia,Australia etc.

Characteristics of our manhole cover:

1. Material: cast gray iron, ductile iron.

2. Shape: round, square, rectangle and triangle.

3. Diameter: from 200mm to 1200mm.

4. Weight: from 7kg to 154kg or according to customers\' requirment

5. Packing: in wooden pallet with plastic layer

6. Annual output: 10,000 tons

7. Coating: black bitumen or Coating as per customers\' requirement

8. Use :municipal engineering, Traffic, pavement ,electronics,telecom, cable, petroleum, chemical industry, or drainage system and industrial facilities of valve well.

Clear Opening: 390*390mm

Frame size: 490*490mm

Frame depth: 75

Testing Loading: D400

Material: Ductile iron GGG500-7&400-12

Standard : EN124

1. Advantage of our Manhole Covers

1) Can supply all kinds of load class Product such as A15/B125/C250/D400/E600/F900

2) Against theft and safety, double sealed, watertight type

3)material No. GGC50(DIN1693-73),QT500-7(GB/T1348-1988), 80-55-06(ASTM A536), FCD500(JISG 5502-2001),500/7(BS2789:1985).

4)Free charge of design.

5) 3 day pay for ready if the request in storck.

2. Detailed information of manhole cover

1) Various manhole cover made by GX Foundry strictly conform to standard and free from sand holes, blowholes,distortion or any other defects

2)Processes:

a) Automatic machine lines

b) Moulding boards

c) Green sand with hand moulding

3)Guarantee: GX Foundry will replace any heavy duty castings that have been properly installed and broken in normal use,free of charge after receipt of the broken castings.

Our Services

Design - Manufacture - Sale - Service

Any sizes and types of Cast Iron manhole covers / gratings can be customized.

Product Quality:

Service life: 30 years . (We guarantee that our manhole covers won't break and out of shape after 30 million times roller

compaction. ) High strength, high elongation and high corrosion resistance's ductile cast iron be used as the raw material

for making manhole covers. Its strength is much higher than No.45 superior carbon steel, 3~5 times higher than common

cast iron covers. 10~30 times higher than cement, resin, steel fiber and so on.

1. Manhole cover and road grate sample can be sent.

2. Customer marking acceptable

3. AutoCAD design

4.As the independent thrid part to check the product for oversea customer and supply the lawfull product quality report.

5.execute the BS EN 124 standard to promise the customer's product quality.

Item | Description | Material | Technical Process |

| 1 | Ductile iron

castings | ASTM A 536-Gr.60-40-18,65-45-12,80-55-06,80-60-03;

DIN-GGG40,GGG50,GGG60,GGG70;

JIS-FCD40,FCD50,FCD60,FCD70;

BS-Gr370-17,Gr420-12,Gr500-7,Gr600-3,Gr700-2;

NF-FGS370-12,FGS400-12,FGS500-7,FGS600-3,FGS700-2; | Green-sand moulding

Resin-sand moulding

Lost foam cast

Shell-core cast

Electric-furnace smelting |

| 2 | Grey iron

castings | ASTM A48-No.20,25,30,35,40,45,50;

ASTM A126-Class A, Class B, Class C;

DIN-GG10,GG15,GG20,GG25,GG30,GG35;

JIS-FC10,FC15,FC20,FC25,FC30,FC35;

BS-Grade 150,180,220,260,300,350;

NF-FGL150,FGL200,FGL250,FGL300,FGL350; | Green-sand moulding

Resin-sand moulding

Lost foam cast

Shell-core cast

Electric-furnace smelting |

| 3 | Carbon steel

castings | ASTM A216-Gr. WCB, Gr. WCA, Gr. WCC;

ASTM-415-205, 450-240, 485-275, 80-40;

DIN- GS-C25(1.0619), GS-38(1.0416),

GS-45(1.0446), GS-52(1.0552), GS-60(1.0558);

JIS-SC410, SC450, SC480, SCC5;

BS-A1, A2, A5;

NF-GE230, GE280, GE320, GE370 | Soluble glass sand moulding

Resin-sand moulding

Lost wax casting

(Investment casting)

Lost foam cast

Shell-core cast

Electric-furnace smelting |

| 4 | Stainless steel

castings | ASTM-CF-8M, CF-8, CA-15, CA-40, 316, 304;

DIN-G-X6CrNi18 9(1.4308), G-X7Cr13(1.4001)

G-X20Cr14(1.4027), 1.4408;

JIS-SCS13, SCS 1, SCS 2, SCS 14A;

BS-304C15, 410C21, 420C29, 316, 304;

NF-Z6CND18.12M, Z6CN18.10M, Z12C13M, Z20C13M | Soluble glass sand moulding

Resin-sand moulding

Lost wax casting

(Investment casting)

Electric-furnace smelting |

| 5 | Alloy steel

castings | DIN-GS-40Mn5(1.1168), GS-20Mn5(1.1120);

GS-37MnSi5(1.5122), GS-34CrMo4(1.7220);

JIS-SCMn3, SCW480, SCSiMn2, SCCrM3, SCMnCR3;

ASTM-LCC

UNS-J02505, J13048

NF-G20M6, G35CrMo4 | Soluble glass sand moulding

Resin-sand moulding

Lost wax casting

(Investment casting)

Electric-furnace smelting |

Please contact us for more information:

All the pattern or words on the surface of manhole cover you need, we can manufacture it for you.I represent all my company members welcome every golbal friends to visit our company for our more development and good bussiness with you.

Packaging & Shipping

Standard export packaging. Client's suggestions can be accepted.

We assure you of our best services at all times!

WeiFang Shengao Machinery Co., Ltd is located in WeiFang the famous city in China and the world center of kites. It is 140 kilometers far away from Qingdao port, the transporation is very convenient. Our company use the location advantages of ShanDong province to integrate resources so that we can processing according to the drawings of customers. We mainly undertake the casting parts, machined parts and other products. Our Import and Export Department have many years experiences of foreign trade, products are mainly exported to the United States, Denmark, Italy, Russia, Australia etc.

Over the years, company adhere to the guideline for management of "Quality first, Reputation first, Delivery just-in-time, Price best". We will try our best to improve the technical level and perfect the enterprise management. Our company will depend on superior quality of products and sincere service to cooperate with dometic and overseas, new and old customers and establish eternal friendship to create a bright future.