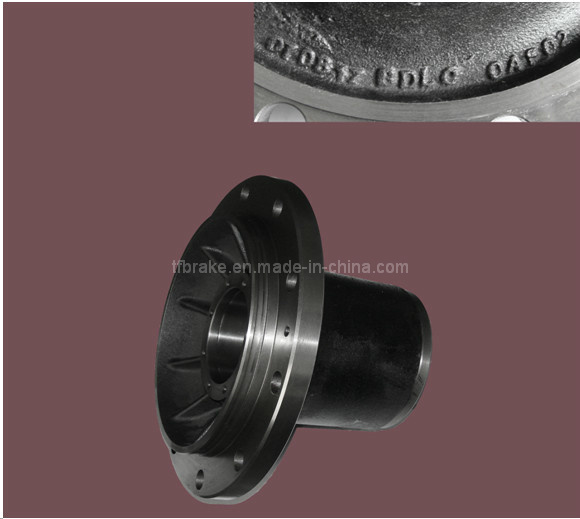

Casting iron wheel hub 1.wheel hub nodular graphite iron casting.

2.equipped with Disa sand process line.

3.With ISO9001:2000 and ISo/TS16949:2009 certificate4. OEM Service/Design Service/Buyer Label

5. OE Quality Bearing Design( FIT / FORM / FUNCTION )

6.Wide Product Range(Customers' drawing or samples are accepted)

7.Guaranted Quality at Satisfactory's Price

8.Prompt Delivery Time

9. Excellent Customer Service

Product Description: Iron casting

1.Title:OEM castings

2.Material: ductile iron, compacted(vermicular )graphite cast irons, gray iron

3. Product weight: 0.5kg to 40kg made by Disa line,and 30Ton made by Tokyu ,Hunter,HWS

4. Processing:casting,machining and coating

5.Techinics:shell mold casting,sand casting,investment casting and lost foam casting

Packaging & Shipping:

Packing methods:carton,pallet,wooden case

Company Information: Weifang Taifeng Brake Factory (Taifeng) was found in June 2003, with fixed asset of 200 minllion RMB and registered capital 20 million RMB. Taifeng is a large enterprise involed in stamping, casting, machining.Taifeng has got the Iso 9001:2000 and ISO/16949:2009 certificates.Taifeng has one American Hunter production line and two Japanese Tokyu casting lines.Annual production of ductile casting parts are more than 70,000 tons. Taifeng has four casting workshops and one hot core mold workshop and one cold core mold workshop, as well as advanced whole series of test equipments to make sure the quality is perfect.  Why Choose Us

Why Choose Us- Taifeng have been engaged in Casting and Machining industry for more than 10 years.

- The whole production cycle is monitored by our Quality Management System ISO 9001:2000 and ISO/TS16949 certificates.

- We now supply all forms of casting parts and cnc machining parts:lost wax investment casting, sand casting, die casting, gravity casting and cnc machining services.

- Rich OEM service experience.

- Our products has been sold to more than 30 countries, we are very familiar with the whole markets, especially for Europe and North America markets.

- Our Commitment & Responsibility:

1. Strict Quality control

2.Competitive Price

3.Quick Response To Any Inquires,Complaint,Technical Problem,etc

4.Timely Delivery

5.Small Quantity Acceptable

|

Our Features |

|

Process |

Investment Casting,Silicon sol casting,Die Casting,Sand Casting,Gravity Casting,etc |

|

Material |

Stainless Steel,Carbon Steel,Alloy Steel,Aluminum,Copper,Ductile Iron,Grey iron,etc |

|

Material Grade |

GB, ASTM , AISI , DIN , BS, JIS, NF |

|

Weight |

0.01 kg~150kg |

|

Accuracy |

Class CT4~CT11 |

|

Surface Roughness |

Up To Ra1.6~Ra6.3 |

|

Applied Software |

Proe ,Igs , Stp , Catia,Auto CAD , PDF, Jpeg, Jpg, Png,etc |

|

Production Capacity |

More Than 1000MT Per Month |

|

Heat Treatment |

Anneal,Quenching,Normalizing,Carburizing,Polishing,Plating, Painting,etc |

|

Machining Equipment |

CNC Center , CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc |

|

Measuring Tool |

CMM , Projector, Vernier Caliper, Depth Caliper, Micrometer,Pin Gauge, Thread Gauge , Height Gauge,etc |

|

QC System |

100% Inspection Before Shipment |

|

Application |

Auto Parts, Wheel Hub,Leaf Spring Lifting Ear,Brake Base Board, |

|

Brake Shoe,Brake Caliper,The Other Automobile Casting parts |

|

|

|

Lead Time |

Depends On Order Quantity.Normally 15~40 Days. |

|

Certification |

ISO9001:2000,ISO/TS16949 |

|

Payment Terms |

T/T , L/C, D/P , D/A,etc |

|

Shipment Terms |

FOB , CFR, CIF,EXW,DDP,DDU,FCA,etc |

Weifang Taifeng Brake Factory was found in June 2004, which is wholly owned subsidiary of Shandong Taiqi Investment Holding Group and governs the Shanxi Taifeng Auto Brake System Co., Ltd. We specializes manufacturing and exporting of auto parts. Our leading products are Wheel Hub, Disc Brakes (pneumatic, hydraulic)and Drum Brakes(pneumatic, hydraulic)...We provide excellent products and services in modular supplying mode.

With total areas of nearly 800 square meters and assets of 650 million RMB, Taifeng and its subsidiary currently have 1200 employees and 125 professional technicians and 38 senior engineers. Taifeng adopts 572 international advanced numerical control equipments and 35 first-class CNC equipments. Also, it founds the Shandong Technical Center with advanced facilities.

Our company was granted to certificate of ISO9001: 2000 Quality Management System, ISO/TS 16949: 2002 Quality Management System. Products of the company have been authenticated by China Certification Center for Automotive products and our company has the management right of import and export trade by itself.

Currently, with annual output of 600, 000 sets of disc brakes, 1.2 million sets of heavy truck and light truck drum brakes and 1 million wheel hubs, Taifeng has built a long term coorperation with big famous manufactures like FAW, Baoding Great Wall, Beijing Benz and Beiqi Foton, Sinotruck, Jianghuai Automobile etc. The products have a ready market in domestic, we have a variety of products exported to the United States, Australia, Spain and other countries and regions.

Our company supplys different kinds of products. High quality and favaroble price. We' Re pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.