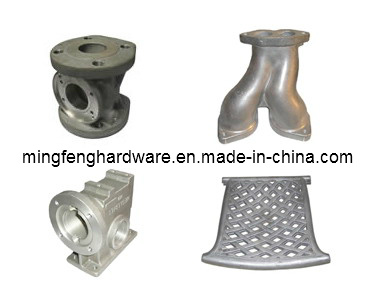

Many of the engineering properties of steel can be realized with Ductile Iron Casting. It has the ability to be cast in heavier sections and can be used to produce larger castings than malleable iron. Ductile Iron Casting has replaced forgings, weldments and steel castings in an ever increasing number of applications.

Ductile Iron Casting is particularly well suited for:

Valves

Pump - Gears and Rollers

Spring Hangers

Suspension Parts

Wheel Hubs

Bearing Caps

Hardware

Universal Joints

Threadless Connectors and Flanges

Various Automotive and Agricultural Items.

Molten metal is injected, under pressure, into hardened steel dies, often water cooled. Dies are opened, and castings are ejected.

Metals:

Aluminum, Zinc, Magnesium, and limited Brass. Stainless steel.

Size Range:

Not normally over 2 feet square. Some foundries capable of larger sizes.

Tolerances:

Al and Mg ± . 002"/in.

Zinc ± . 0015"/in.

Brass ± . 005"/in.

Add ± . 001" to ± . 015" across parting line depending on size.

Surface Finish:

32-63RMS

Minimum Draft Requirements:

Al & Mg: 1° To 3°

Zinc: 1/2° To 2°

Brass: 2° To 5°

Normal Minimum Section Thickness:

Al: . 03" Small Parts: . 06" Medium Parts

Mg: . 03" Small Parts: . 045" Medium Parts

Zinc: . 025" Small Parts: . 040" Medium Parts

Ordering Quantities:

Usually 2, 500 and up.

Normal Lead Time:

Samples: 12-20 weeks.

Production:

4-8 weeks A. S. A.

Qingdao Mingfeng Hardware Products Co., Ltd is located in Qingdao, one of the largest Sea City in China.

We can supply casting parts, machining parts, welded parts, forged parts and

Stamping parts. We export our parts, especially castings to Italy, Belgium, danmark, Germany, France, USA, Brazil, etc.

The relevant industry: Building industry, machinery industry, household

Appliances industry, and common hardware accessories.

We have advanced casting equipment, milling, turning, and grinding

Equipment, high precision CNC equipment and finishing equipment.

Standard workshop covers an area of 20000 m2, which equiped with facilities:

CNC machining centers;

Die spotting machine;

3-d coordirating instrument;

Wire-cut EDM;

Casting machine(200t-800t);

Heating production lines and machines.

Engineering software:

PRO/e, ug, solidworks, moldflow(EDM), jscast( mold flow analysis )

Certificate: ISO9001, TS1649, SGS.