Main Products

Hot work Tool Steel

1. Hot work Tool Steel Round/Flat bar (H13/1.2344/4Cr5MoSiV1/SKD61)(Brand Product)

High wear resistance, toughness and hot hardness. It is mainly used for extruding, die-castingmold and complex-shaped mold, etc.

2. Hot work Tool Steel (1.2714/L6/5CrNiMo/SKT4)

It is mainly used for manufacturing hot-extrusion die, swage hammers, etc.

3. Hot work tool steel 1.2343/ H11/SKD6/4Cr5MoSiV

High thermal strength, hardness, wear-resistance and toughness.It is mainly used for tools forextrusion; molds for plastics; tools for cold punching and hot sharing.

Cold Work Tool Steel

1. Cold Work Tool Steel Round/Flat Bar (1.2379/D2/Cr12Mo1V1/SKD11)

High wear resistance, necessary toughness and high chromium steel. It is mainly used for high-output pressing mold, circuit board mold etc.

2. Cold work tool steel (D3/1.2080/Cr12/SKD1)

High wear-resistance and high Chrome steel. It is mainly used for punching tools for thin sheets,profile rolls, knives for paper and plastics, shear knives for thin sheets.

3. Cold work tool steel O2/1.2842/9Mn2V

Nice quenching intensity, dimensional stability and good wear resistance. It is mainly used forprecision instruments, small-sized cold pressing mold, ornaments.

Plastic mold steel

1. Plastic mold steel (1.2316/3Cr17Mo)

High Corrosion-resisting mirror surface steel and high-grade mirror mold in weak acid ormoisture environment. It is mainly used for die steel for plastic industry, optical instrument, PVS,etc.

2. Plastic mold steel (1.2311/P20/618/3Cr2Mo)

One of plastic mold steels. It possesses fine polishing property and easy processing. It is mainlyused for dies in plastic industry, such as various large-sized or medium-sized precision plastic moldand low melting point alloy parts.

3. Plastic Mold Steel (1.2738/718/3Cr2NiMnMo)

Mirror surface plastic mold steel. It is mainly used for manufacturing oversize and largeplastic mold, delicate and long-lifetime mold, etc

4. Plastic Mold Steel (1.2083/S-136/SUS420J2/4Cr13)

Corrosion-resisting mirror surface, high-Cr steel and high-grade mirror mold in weak acid ormoisture environment, mainly used for PVC, optical instrument, etc.

Alloy structural steel

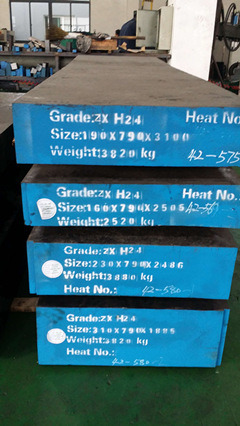

1. Alloy structural steel 42CrMo/4140/SCM440

High quality structural alloy steel. It is mainly used for making various kinds of machinery,automobile, mining spare part.

Ningbo beilun machinery forging company is situated in Daqi industry park of Beilun area, near to the Wanqiu Mountain and 30km to the Ningbo airport. It has been established for more than 20 years with convenient transportation around this beautiful environment.

It is a comprehensive enterprise integrating forging, sawing, rough machining and processing center and manufactured products into one.

As market's growing up, the Xunhu commerce co. Ltd was built covering 5, 000 square meters. Based on the production, sales, and research, the company closely cooperates with a famous enterprise and a university.

Implementing the guidelines of precision, criterion, caution and strictness, the company advocates the quality management principle "No defect on goods quality, zero tolerance on quality problem, and 100% to quality target".

By the means of lean production, fine management, improvement and promotion of activity and 6Son-site management, the company builds the marketing system of accurate consulting before sales, strict and careful management and tracking service after sales.

Besides offering excellent products to customers, the company also forms a close alliance with factories of heat treatment against the mould steel's problems, such as cracking, collapse, local deformation and fissure. And the service as followed:

1. The materials and heat treatment are under control according to customer's requirements

2. The vacuum quenching and normalizing are finished alone to meet our demand.

3. Customers and the company negotiate and cooperate with the factory which conveys the heat treatment based on clients request.

Advantages;

1. It will avoid bringing inconvenience to customers while problems happening.

2. It allows fully play to our products property.

The company would like to become your business partner so that we can make innovative promotion to win the market development.