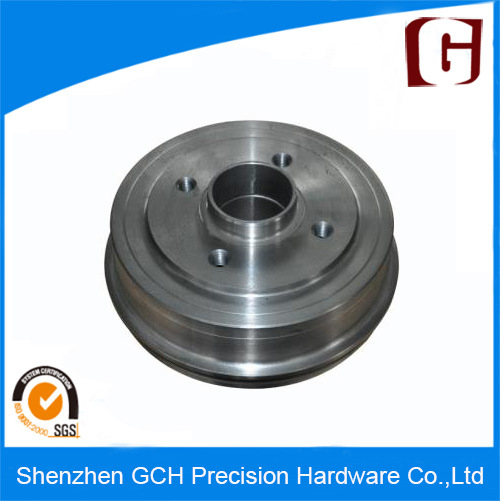

customized Stainless Truck Die Casting Parts

Product Description:

1. OEM and ODM 100%

2. High quality

3. Best service and best products

4. Advanced technology and equipment.

Product features:

1. Application: Auto parts/Engine parts/Agriculture equipment parts/LED Lighting parts/Train parts and so on.

2. Material: 6061,8407, SKD11 or per customer's requirements.

3. Die casting equipment: 180T/280T/400T/600T/800T/1000T;

4. Mold material: H13/1.2344

5. Mold life: 50, 000 shots;

6. Main process:

1> Die casting;

2> Deburring;

3> Sandblasting;

4> Machining;

5> Leakage test;

6> Surface treatment

Quick introduction about our capability:

Certificate: | ISO9001: 2000 |

| OEM & ODM products range: | Auto parts, Engine parts, Agriculture equipment parts, Lighting parts, Train parts, etc. |

| Die casting equipment capability: | 180T/280T/400T/600T/800T/1000T |

| Product weight: | From 0.05~10kg |

| Machining equipment: | CNC, Lathe machine, Milling machine, Drilling machine, and so on |

| Test equipment: | Optical Spectrum Analyzer, CMM, Hardness test equipment, Tensile test machine |

| Surface treatment: | Powder coating, Anodization, Chrome plating, Painting, Sand blasting |

Our company is specialized in die casting products& CNC machining parts. We provide One-stop Service, Please kindly check our details.

1. Aluminum Die Casting Mold Material: 6061,8407, SKD11 or per customer's requirements...

2. Mold Design: According to Technical Drawings or Samples.

3. Mold Lead Time: 20 ~ 30 days

4. OEM and ODM orders are all Welcomed.

5. High Quality & Competitive Price & prompt delivery.

6. Advanced equipment and excellent R&D Team, Highly skilled manufacturing

Process, Strict quality Control System.

How we can keep the high quality parts always?

1.All our material will be tested by SGS before production

2. Full control of process:

(1).During the part production,our QC worker will inspect the part size every one hour,this will help us to keep the correct tolerance during production

(2). When the parts machining finished,they will be arranged to have surface finished(such as anodize or powder coated),after that,our QC worker will inspect the parts again,because after surface finished,part tolerance may be difference sometimes,if there is any defective parts we found,we will pick them out directly

(3). Before shipping,our package worker will check the part surface and see if there is any scrach or any other thing that affect the part looking,if yes,pick them out.

What can we do for you?

1.Professional,Competitive price and Fast delivery time

We engaged in this area for almost 10 years, skilled engineer can help you process the project well and perfect,

also we own our factory,that we can control the cost and delivery time very well.We can try best to meet your request.

Protect our customer profit well.

Even we have very strictly quality control system,but we still can`t promise every part you received will 100% perfect,

so if there is any defective part you received,you just need to offer us the evidence(such as picture),we will check and

confirm it.After that,we will repair or redo them.

Because of our strictly quality control system,so we have the confidence to promise our customer with this.Please kindly

noted that it`s our advantage compare with others,we realize that only the high quality and good service can keep the friendly

and long-term business relationship with our customer and it`s also the only way for an enterprise to be existed...

Contact information:

Contact person:Stephen Song

Tel:86-(755)-29931388

Fax:86-(755)-29931288

Add: 1st Building, A area, Buyong Industiral Zone, Shajing Street, Bao'an district, Shenzhen, China.

Established in 2010, Shenzhen GuoChangHong Precision Hardware Co., Ltd is a professional manufacturer specialize in the manufacturing precision CNC machining components and die casting parts. We produce products in many fields, such as electronic cigarette parts, automotive spare parts, aerospace machining parts, industrial sensors, LED lighting parts, mechanical components and sport parts and so on.

We have dozens of support equipment in our workshop, such as CNC milling machine/Horizontal CNC milling machine/4 Axis CNC Milling machine/5 Axis CNC milling machine/CNC Turing machine/Grinding machine/wire Cut machine, also have inspection equipments such as two dimensional and three dimensional measuring instrument, digital projector, video measuring system, surface finishing testing machine...We're equipped to manufacture, inspect, assemble and deliver virtually any precision component as customer desire

From our establishment, We has always put quality first, customer first, pioneering and innovative, and sustainable management, we commit to provide good service to our customer and become partner of many famous enterprise, We believe it is our responsibility to take all steps necessary to protect our environment.

We are looking forward to building long-term business relationships with you for mutual benefit. Customers from worldwide are warmly welcome to contact us. Welcome you to visit our factory for your business!