Permanent mold casting is metal casting process that employs reusable molds ("permanent molds"), usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminum, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.

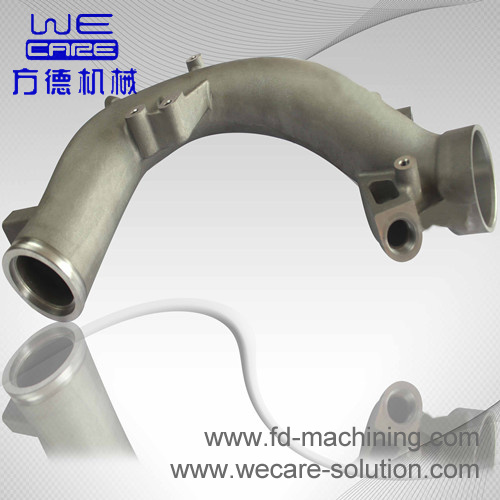

Typical parts include gears, splines, wheels, gear housings, pipe fittings, fuel injection housings, and automotive engine pistons

Ductile iron casting product

The production process is auto lathe, CNC machining, CNC turning, CNC cutting, CNC milling, threading, tapping, drilling, etc. It has smooth surface and professional process design, and has strict chemical composition test before pouring.

Process Casting, die casting, precision casting, investment casting and sand casting

Material GGG50/GGG60/GGG40-15/GGG40-18

Designs As customer' s drawings or samples

Coating Blank bitumen coated, without coating or coating as customer' s requirement

Machinery and Equipment CNC machining, milling machine, drilling machine, boring machine, etc

1. Tight tolerance, Provide ODM/OEM service

2. Advanced equipment, excellent R&D teams

3. ISO9001/2001, TS16949 approval, Strict quality control system

4. Precision machining, CNC machining, milling, turning, drilling, grinding, stamping, bending, casting, forging, punching, welding, laser cutting.

5. Various material available including Carbon steel, Stainless steel, aluminium and aluminium alloy, Brass and Brass alloy, Plastic etc.

6. Standard: According to the dimension tolerance of machining of customers' requirement.

7. Surface roughness: Ra0.8-3.2

8. Weight: Ranging from 0.50g to 10000kg

9. Surface finish: Polishing, oiled (rust-prevented), zinc-plated, nickel-plated, chrome-plated, hot-galvanized, sandblasting, painting, powder-coating.

10. Small quantity accepted

11. Usage: Auto & motorcycle, mining machinery, building industry, electrical and electronic products, industrial machinery and equipment and transportation. etc.

12. Inspection: In-house or third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: Hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

1. OEM/ODM/custom service is provided

2. High precision, tolerance can be ± 0.002mm

3. No MOQ

4. Fast lead time

5. DIN, JIS, ASTM, AISI, BS, GB standard

| Package | According to customer' s requirement; |

| Tolerance | CNC machining parts: +/-0.002 |

| Service available | We supply pre-production samples for customer final confirmation before mass production; |

| Certificate | SGS

CE

ISO |

Wecare Industrial Company is a world leader in the custom design and manufacture of metal component parts.

We are a full-service company. Our experienced engineers and manufacturing staff are ready to assist you with the design of your custom industrial components and produce the finished part. Our manufacturing capabilities include machined parts, die castings, sand casting and investment castings using the most advanced equipment.

Our services including the following;

. Engineering design of your custom component part

. AutoCAD and Solidworks 3-D support and service

. Production process support and quality control

Please give Wecare an opportunity to work with you. We pride ourselves on the high quality of our engineering and manufacturing, superior quality control and on-time delivery of your parts. Just as important is that we offer very aggressive prices in an effort to build a strong, long term relationship with our customers. We can provide you with a list of our customers upon request.

Wecare is headquartered in the city of Changzhou, Jiangsu Province, China. We have a satellite office in New Jersey for the benefit of our many USA customers.

What concerns you, What we care and focus.

You Trust, We care

We care quality-consistency and timely delivery;

We care to save your costs, to increase your competitiveness;

We care not only present cooperation, but future and long-term collaboration as well