Proces: sand casting or precision casting

Material: aluminum, steel ,iron

Material: GradeGB, ASTM, AISI, DIN, BS, JIS, NF

Weight: 10g~150kg

Accuracyclass: CT4~CT7

Surface Roughness: up to Ra1.6~Ra6.3

Applied software: ProE (. igs, . STP), Auto CAD, PDF, JPEG, JPG, PNG

Production capacity: more than 1500MT per year

Heat Treatment: anneal, quenching, normalizing, carburizing, polishing, plating, painting

Machining Equipment: CNC center, CNC machines, turning machines, drilling machines, milling machines, grinding machines

Measuring Tool: CMM, vernier caliper, depth caliper, micrometer, pin gauge, thread gauge, height gauge

QC system: 100% inspection before shipment

MOQ: 500kg

Lead Time: sample fast, lot production depends on customers' request

Certification: ISO9001

Payment Terms: T/T, L/C, D/P, D/A

Shipment Terms: FOB, CFR, CIF

OUR ADVANTAGES:

1) Experience in casting and served customers all around the world.

2) More than 500 professional employees working together to pursue a wonderful career.

3) International advanced-level equipment such as CNC, numerical lathes, furnance, welding equipment, CMM and detect &testing equipment we used to ensure our product's quality.

4) OEM service, you demand is our pursued.

5) ISO quality control

6) Standard: ASTM BS JIN DIN etc

7) Applied software for specification drawings: PRO/E, Auto CAD, Solidwork, CAXA, UG. etc

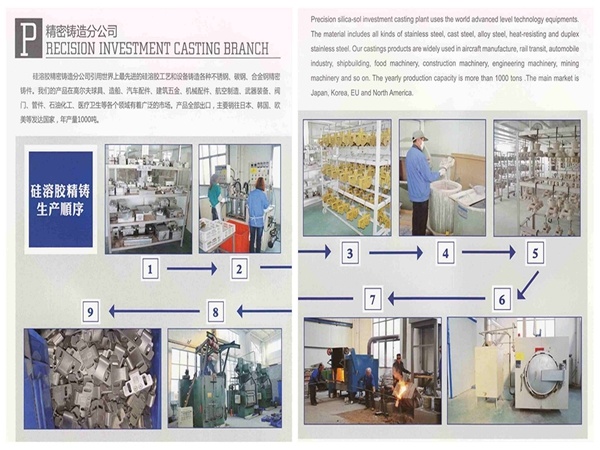

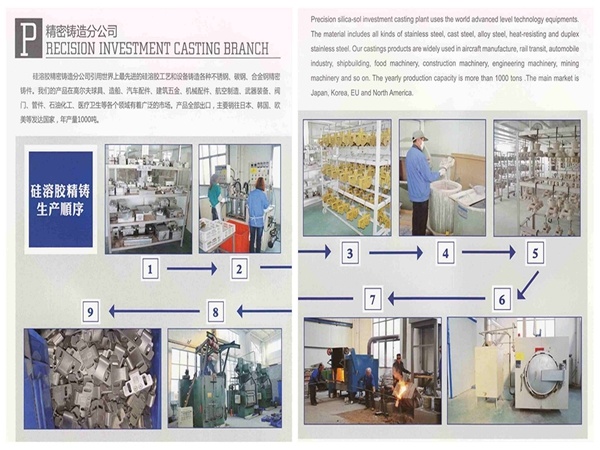

Workshop facility of investment casting

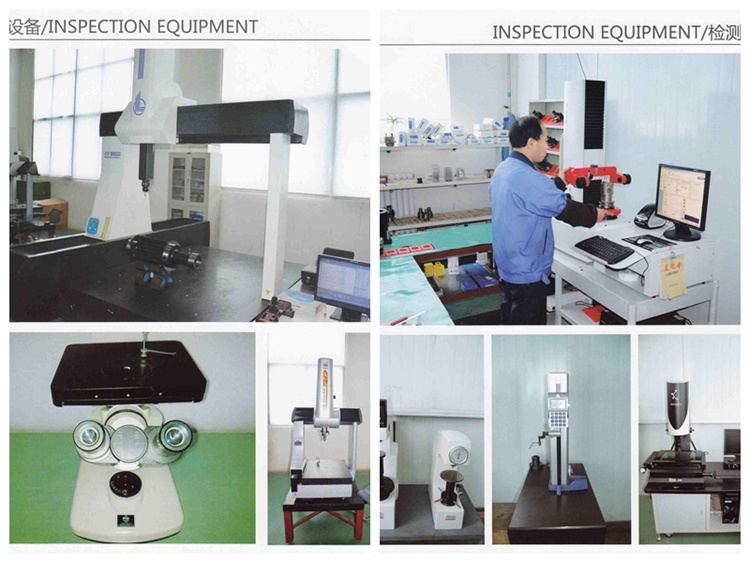

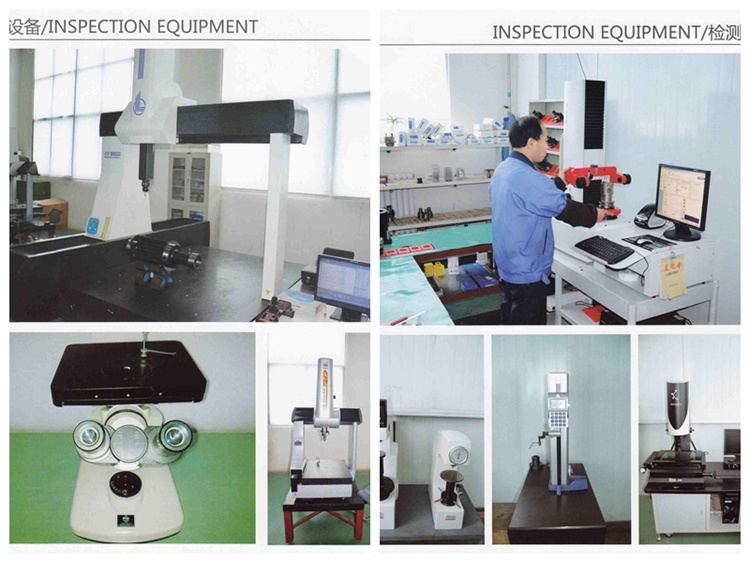

QC Equipment CMM for investment casting

Facility may involved for Q&C:

Material:

l. Chemical composition:

Ø OBLF Spectrometer with 29 channels in bi-metal of AL+FE

2. Mechanical Property

Ø Hardness test

Ø Mechanical property inspection

Ø Impact inspection

3. Microstructure:

Ø Microscope Metallographic Analysis as per AQL based on heating number

4. Structure tightness

Ø Destruction test

Ø Weight test

Crack inspection:

l.MT

2.UT

3.X-ray

Coating test:

lCoating thickness tester

lSalt spray test

Dimension:

l. Conventional gauge

2. Go & No-go gauge

3. CMM

Leakage check

Press load test

Ø Will be effected acc. to different projects.

Output of our Q. C.:

1. Finished products:

Ø meets AQL requirement. 50ppm, 500ppm, 1000ppm, 5000ppm may vary acc. to project.

2. Q. C report:

Ø Dimensional report(all dimension/key dimension)

Ø Material report in 3.1b acc. to EN10204(2004)

Ø Other detailed report like heat treatment curve, crake testing,

Ø pressure testing, leakage inspection also available if needed.

Product Range of investment casting

Our company specializes in the mechanical parts and metal components.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

We are able to provide a wide range of products. Have been successfully supplying Pump Parts, Motor Parts, Construction Machinery Parts, Agricultural Machinery, Drainage System, Manhole cover, Park bench, Railway parts to our current customers. Our main product line includes sand casting, precision/investment/lost wax casting, forging and machining. Materials varies from grey iron, ductile iron, bronze, aluminium, steel, stainless steel, and so on.

| PROCESS | MATERIAL | STANDARD |

SAND

CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM

BS

JIS

DIN

etc |

| Furan Resin Sand |

| Cold Harden Resin Sand |

INVESTMENT

CASTING | Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum |

| Silica Sol |

| FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum |

| Die Forging |

| Roll Forging |

| STAMPING MACHINING | STAMPING MACHINING | All metal material |

Qingdao Xinghe Machinery Co., Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

Our main product line includes sand casting, precision casting, die casting, forging, stamping, welding and CNC machining. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.